Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (3): 98-104.doi: 10.19964/j.issn.1006-4990.2023-0421

• Environment·Health·Safety • Previous Articles Next Articles

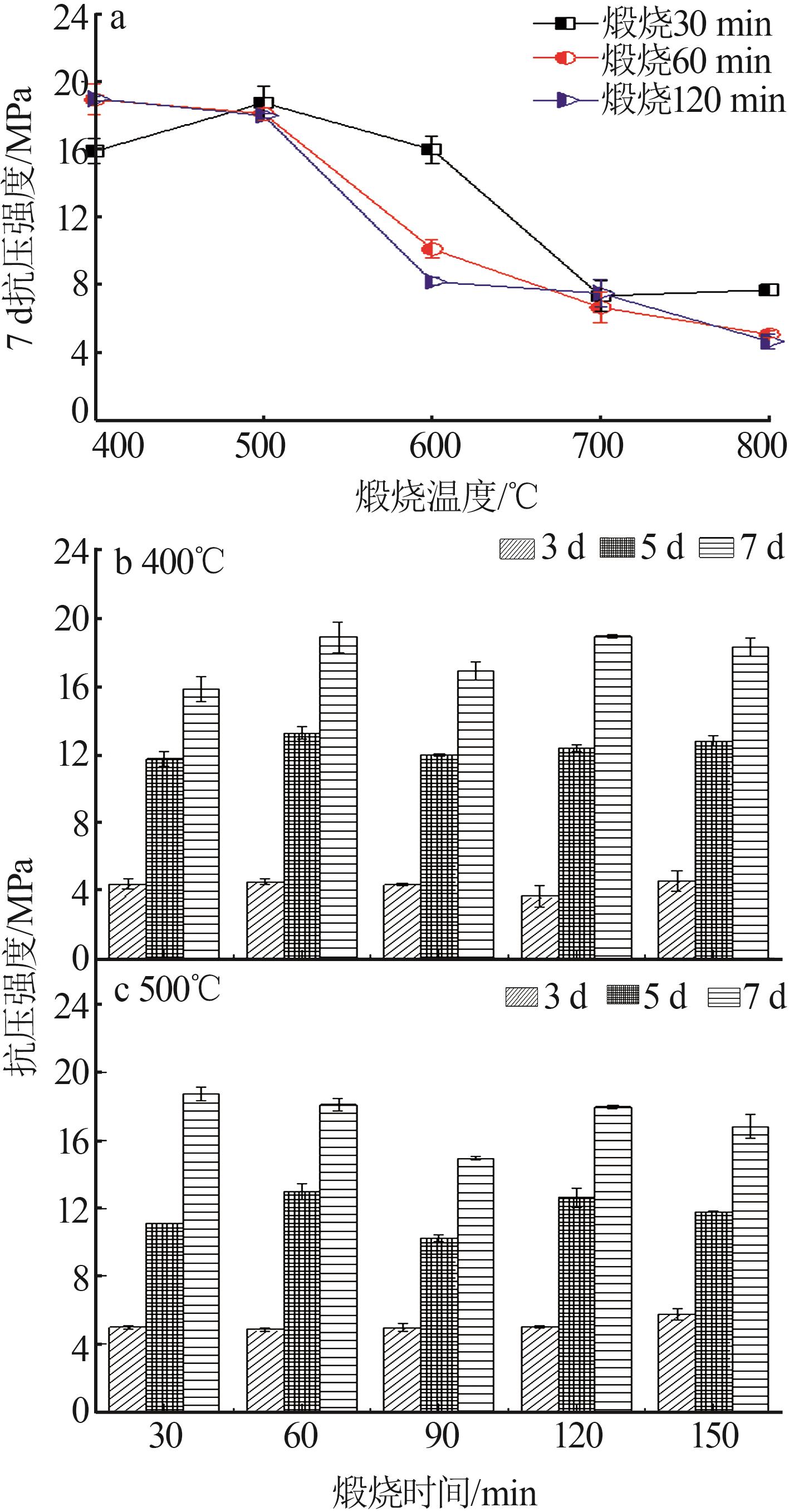

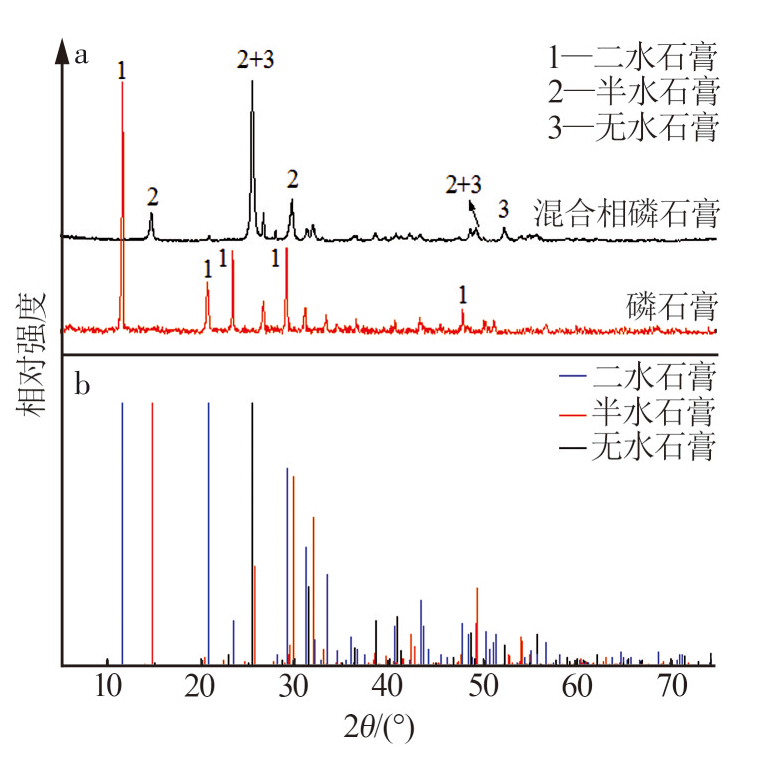

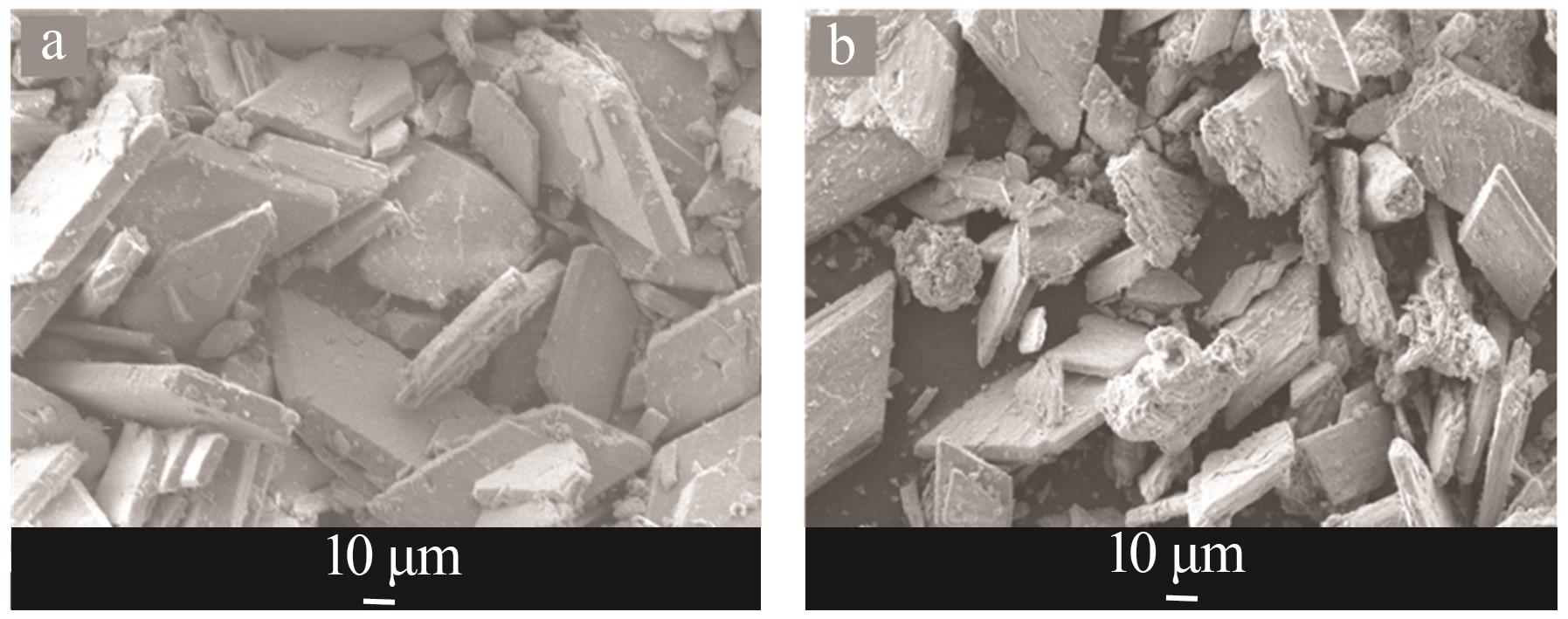

Research on preparation and early performance of mixed phase phosphogypsum-based cementing materials

WANG Ruting1,2( ), ZHAO Xiaorong1,2,3, HUANG Xuquan1,2,3,4(

), ZHAO Xiaorong1,2,3, HUANG Xuquan1,2,3,4( ), WANG Haojie1,2,3, XUE Fei1,2,3, CAI Jiawei1,2

), WANG Haojie1,2,3, XUE Fei1,2,3, CAI Jiawei1,2

- 1.Engineering Research Center of Eco-environment in Three Gorges Reservoir Region,Ministry of Education,China Three Gorges University,Yichang 443002,China

2.College of Hydraulic & Environmental Engineering,China Three Gorges University,Yichang 443002,China

3.Yichang Key Laboratory of Solid Waste Disposal and Resource Utilization,China Three Gorges University,Yichang 443002,China

4.Hubei Province Enterprise-college Cooperation Innovation Center for Comprehensive Utilization of Phosphogypsum,Yichang 443002,China

-

Received:2023-08-23Online:2024-03-10Published:2024-03-14 -

Contact:HUANG Xuquan E-mail:1819373548@qq.com;huangxuquan@126.com

CLC Number:

Cite this article

WANG Ruting, ZHAO Xiaorong, HUANG Xuquan, WANG Haojie, XUE Fei, CAI Jiawei. Research on preparation and early performance of mixed phase phosphogypsum-based cementing materials[J]. Inorganic Chemicals Industry, 2024, 56(3): 98-104.

share this article

| 1 | WEI Zhongqi, DENG Zhengbin.Research hotspots and trends of comprehensive utilization of phosphogypsum:Bibliometric analy-sis[J].Journal of Environmental Radioactivity,2022,242:106778. |

| 2 | 吴浩,韩超南,汤昱.我国磷石膏资源化利用研究进展[J].现代化工,2023,43(3):18-21. |

| WU Hao, HAN Chaonan, TANG Yu.Research progress on reutilization of phosphogypsum in China[J].Modern Chemical Industry,2023,43(3):18-21. | |

| 3 | 崔荣政,白海丹,高永峰,等.磷石膏综合利用现状及“十四五”发展趋势[J].无机盐工业,2022,54(4):1-4. |

| CUI Rongzheng, BAI Haidan, GAO Yongfeng,et al.Current situation of comprehensive utilization of phosphogypsum and its development trend of 14th Five-Year Plan[J].Inorganic Chemicals Industry,2022,54(4):1-4. | |

| 4 | QIN Xiantao, CAO Yihu, GUAN Haowei,et al.Resource utilization and development of phosphogypsum-based materials in civil engineering[J].Journal of Cleaner Production,2023,387:135858. |

| 5 | MURALI G, AZAB M.Recent research in utilization of phosphogypsum as building materials:Review[J].Journal of Materials Research and Technology,2023,25:960-987. |

| 6 | REN Zhisheng, WANG Lu, WANG Hao,et al.Solidification/stabilization of lead-contaminated soils by phosphogypsum slag-based cementitious materials[J].Science of the Total Environment,2023,857:159552. |

| 7 | 潘祖德,刘琦,曹阳,等.磷石膏基矿井充填材料制备及其性能研究[J].无机盐工业,2022,54(11):90-95. |

| PAN Zude, LIU Qi, CAO Yang,et al.Study on preparation and properties of phosphogypsum based mine filling materials[J].Inorganic Chemicals Industry,2022,54(11):90-95. | |

| 8 | 刘路珍,陈德玉,何玉龙,等.磷石膏粒径及pH值对其复合胶凝材料的影响[J].非金属矿,2015,38(3):5-8. |

| LIU Luzhen, CHEN Deyu, HE Yulong,et al.Effect of particle size and pH value of phosphogypsum on composite binders based on phosphogypsum[J].Non-Metallic Mines,2015,38(3):5-8. | |

| 9 | 苗训,陆跃贤,付汝松,等.半水磷石膏参与固化原状磷石膏制备复合胶凝材料[J].无机盐工业,2022,54(4):10-16. |

| MIAO Xun, LU Yuexian, FU Rusong,et al.Hemihydrate phosphogypsum as used to solidify the raw phosphogypsum to prepare composite cementitious material[J].Inorganic Chemicals Industry,2022,54(4):10-16. | |

| 10 | DENG Fang, YE Jian, LIU Yanling,et al.Influence of cement on properties of calcined phosphogypsum based composite cementitious materials[J].Journal of Materials Research and Technology,2023,24:3145-3156. |

| 11 | 许晴莹,杨鼎宜,吕伟,等.球磨时间对磷石膏基胶凝材料性能影响研究[J].无机盐工业,2022,54(5):101-108. |

| XU Qingying, YANG Dingyi, Wei LÜ,et al.Effect of grinding time on properties of phosphogypsum based cementitious materials[J].Inorganic Chemicals Industry,2022,54(5):101-108. | |

| 12 | 冯洋,杨林,曹建新,等.磷石膏煅烧改性制备自流平砂浆的研究[J].硅酸盐通报,2020,39(9):2891-2897. |

| FENG Yang, YANG Lin, CAO Jianxin,et al.Calcining modification of phosphogypsum to prepare self-leveling mortar[J].Bulletin of the Chinese Ceramic Society,2020,39(9):2891-2897. | |

| 13 | 李德星,郭荣鑫,林志伟,等.磷石膏制备α半水石膏的研究现状[J].硅酸盐通报,2022,41(3):860-869. |

| LI Dexing, GUO Rongxin, LIN Zhiwei,et al.Research status of preparation of α-hemihydrate gypsum from phosphogypsum[J].Bulletin of the Chinese Ceramic Society,2022,41(3):860-869. | |

| 14 | 李凤玲,钱觉时,倪小琴,等.快烧对磷石膏脱水相组成及胶凝性能的影响[J].硅酸盐学报,2015,43(5):579-584. |

| LI Fengling, QIAN Jueshi, NI Xiaoqin,et al.Effect of fast-firing on dehydrated phase composition and cementitious property of phosphogypsum[J].Journal of the Chinese Ceramic Society,2015,43(5):579-584. | |

| 15 | 杨敏,曹建新,谢燕.半水石膏激发Ⅱ型无水磷石膏的研究[J].武汉理工大学学报,2010,32(18):63-65. |

| YANG Min, CAO Jianxin, XIE Yan.Activation of anhydrite-Ⅱ phosphogypsum by hemihydrate[J].Journal of Wuhan University of Technology,2010,32(18):63-65. | |

| 16 | 董江峰,姜明明,赵小蓉,等.改性β-半水磷石膏固化含铅淤泥的性能及机理[J].化工环保,2022,42(2):231-236. |

| DONG Jiangfeng, JIANG Mingming, ZHAO Xiaorong,et al.Properties of lead-bearing sludge cured by modified β-hemihydrate phosphogypsum and its curing mechanism[J].Environmental Protection of Chemical Industry,2022,42(2):231-236. | |

| 17 | ZAKIRA U, ZHENG Kai, XIE Ning,et al.Development of high-strength geopolymers from red mud and blast furnace slag[J].Journal of Cleaner Production,2023,383:135439. |

| 18 | BOHÁČ M, PALOU M, NOVOTNÝ R,et al.Investigation on early hydration of ternary Portland cement-blast-furnace slag-metakaolin blends[J].Construction and Building Materials,2014,64:333-341. |

| 19 | 周富涛,石宗利.磷石膏制备建筑石膏工艺研究[J].新型建筑材料,2007,34(7):48-52. |

| ZHOU Futao, SHI Zongli.Research on the Study on process of building plaster using phosphogypsum[J].New Building Materials,2007,34(7):48-52. | |

| 20 | HU Yueyang, REN X, YE Jiayuan,et al.The reactive products and reactivity of modified red mud and ground granulated blast furnace slag at different alkalinities[J].Construction and Building Materials,2022,346:128471. |

| 21 | 黄照昊,罗康碧,李沪萍.磷石膏中杂质种类及除杂方法研究综述[J].硅酸盐通报,2016,35(5):1504-1508. |

| HUANG Zhaohao, LUO Kangbi, LI Huping.Types of impurity in phosphogypsum and the method of removing impurity research review[J].Bulletin of the Chinese Ceramic Society,2016,35(5):1504-1508. | |

| 22 | 黄绪泉,赵小蓉,唐次来,等.磷石膏基胶结材固结磷尾矿性能及浸出特征[J].环境工程学报,2016,10(10):5957-5963. |

| HUANG Xuquan, ZHAO Xiaorong, TANG Cilai,et al.Properties and leaching characteristics of cemented phosphate tailings backfill with phosphogypsum-based cementation material[J].Chinese Journal of Environmental Engineering,2016,10(10):5957-5963. | |

| 23 | 陈洁,刘亮,赵小蓉,等.甲酸钙对改性磷石膏基材料性能影响[J].非金属矿,2021,44(6):79-83. |

| CHEN Jie, LIU Liang, ZHAO Xiaorong,et al.Effect of calcium formate on the performance of modified phosphogypsum substra-te[J].Non-Metallic Mines,2021,44(6):79-83.[24] HINAA,NANCOLLASG H,GRYNPASM.Surface induced constant composition crystal growth kinetics studies.The brushite-gypsum system[J].Journal of Crystal Growth,2001,223(1/2):213-224. | |

| 25 | HUANG Xuquan, JIANG Mingming, ZHAO Xiaorong,et al.Mechanical properties and hydration mechanisms of high-strength fluorogypsum-blast furnace slag-based hydraulic cementitious binder[J].Construction and Building Materials,2016,127:137-143. |

| 26 | REN Zhisheng, WANG Lu, WANG Hao,et al.Stabilization and solidification mechanism of Pb in phosphogypsum slag-based cementitious materials[J].Construction and Building Materials,2023,368:130427. |

| 27 | TREZZA M A, LAVAT A E.Analysis of the system 3CaO·Al2O3-CaSO4·2H2O-CaCO3-H2O by FT-IR spectroscopy[J].Cement and Concrete Research,2001,31(6):869-872. |

| 28 | ÁLVAREZ-AYUSO E, NUGTEREN H W.Synthesis of ettringite:A way to deal with the acid wastewaters of aluminium anodising industry[J].Water Research,2005,39(1):65-72. |

| 29 | QIAN G R, SHI J, CAO Y L,et al.Properties of MSW fly ash-calcium sulfoaluminate cement matrix and stabilization/solidification on heavy metals[J].Journal of Hazardous Materials,2008,152(1):196-203. |

| [1] | WANG Peixiong, GONG Xiaomei, DING Jiaqi, CAO Hong. Effect of crystal modifier on preparation of α-hemihydrates gypsum from industrial gypsum [J]. Inorganic Chemicals Industry, 2024, 56(4): 112-117. |

| [2] | CHEN Feng, FENG Kang, LI Ming, SHEN Haojie, TIAN Chengtao, TANG Yuan, LI Zhili, HE Dongsheng. Application of organically modified calcium sulfate whiskers in asphalt modification [J]. Inorganic Chemicals Industry, 2024, 56(3): 125-130. |

| [3] | ZHANG Guidong, YANG Xuejiao, GUO Xudong, YANG Lin. Study on hydration properties of type Ⅱ anhydrite prepared by calcination and atmospheric acidification [J]. Inorganic Chemicals Industry, 2024, 56(2): 104-110. |

| [4] | WANG Yanyu, GU Shouyu, HOU Cuihong, JING Hongquan, GUAN Hongling, ZHANG Hui. Sulfur escape and slag physical phase analysis by carbon thermal reduction melting based on phosphogypsum ingredients [J]. Inorganic Chemicals Industry, 2024, 56(2): 86-94. |

| [5] | DENG Hua, HOU Shuomin, LI Zhongjun, XU Gang, CHI Ru′an, XI Benjun. Current situation and prospect of comprehensive utilization of phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(1): 1-8. |

| [6] | XIA Guiying, YANG Liuchun, YUAN Zhiye. Study on direct leaching of rare earth elements from phosphogypsum with sulfuric acid [J]. Inorganic Chemicals Industry, 2024, 56(1): 107-113. |

| [7] | CUI Gengyin, XIE Lang, LU Yuexian, KONG Dewen, WANG Lingling. Optimization of mechanical properties of basalt fiber reinforced phosphogypsum-based composites based on RSM [J]. Inorganic Chemicals Industry, 2023, 55(8): 116-123. |

| [8] | LI Heng, ZHANG Hui, ZI Xuemin. Analysis on calcination process progress of phosphogypsum [J]. Inorganic Chemicals Industry, 2023, 55(6): 27-35. |

| [9] | ZHANG Lei, LI Meng, XIANG Wenguo, HU Jun, CHEN Shiyi, DUAN Lunbo. Feasibility analysis of calcination and decomposition process of phosphogypsum in circulating fluidized bed [J]. Inorganic Chemicals Industry, 2023, 55(6): 85-91. |

| [10] | DONG Xinyu, WANG Haifeng, HE Yue, YANG Pan, WANG Song, YANG Chunyuan, WANG Qin, HUANG Bifang, WANG Jiawei. Exleaching toxicity analysis and harmless treatment of electrolytic manganese residue [J]. Inorganic Chemicals Industry, 2023, 55(5): 85-90. |

| [11] | XU Li, FANG Keneng, BI Yongxiang, YANG Min, CHEN Qianlin. Preparation of modified granular-like CaSO4 and its application in polyvinyl chloride [J]. Inorganic Chemicals Industry, 2023, 55(3): 104-112. |

| [12] | GUO Shuang, XING Dongxian, GUO Xiao, JI Xiaojie, TANG Jianwei, HUA Quanxian, WANG Baoming, LIU Yong. Study on preparation and modification of phosphogypsum-based architectural gypsum [J]. Inorganic Chemicals Industry, 2023, 55(12): 102-110. |

| [13] | LIU Chao, FAN Chuigang, LIU Runguo, YU Dongxue, LI Songgeng. Preparation of α-hemihydrate gypsum from phosphogypsum by flotation and atmospheric trans-crystallization in solution [J]. Inorganic Chemicals Industry, 2023, 55(11): 107-114. |

| [14] | GUO Ze, ZHANG Pengfei, YANG Fan, ZHANG Hanquan, LU Manman. Preparation of β-hemihydrate gypsum by phosphogypsum roasting [J]. Inorganic Chemicals Industry, 2023, 55(10): 106-113. |

| [15] | CHEN Mingsheng,LIU Peng,KONG Dewen,LI Yuan,YU Ke,HUANG Yansen,WU Ningbo,CHANG Juanjuan. Effect of external admixtures on mechanical and thermal conductivity of phosphogypsum composite cementitious materials [J]. Inorganic Chemicals Industry, 2022, 54(9): 113-118. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||