Inorganic Chemicals Industry ›› 2024, Vol. 56 ›› Issue (4): 34-41.doi: 10.19964/j.issn.1006-4990.2023-0277

• Research & Development • Previous Articles Next Articles

Treatment effect and flocculation mechanism of abandoned drilling mud by different flocculants

YANG Bin1( ), LI Yinyue2, DONG Mingkun2, HAN Ximeng2, GUI Xin2, ZHANG Fawen2(

), LI Yinyue2, DONG Mingkun2, HAN Ximeng2, GUI Xin2, ZHANG Fawen2( )

)

- 1.Zhengzhou Ecological Environment Monitoring Center, Zhengzhou 450007, China

2.College of Forestry, Henan Agricultural University, Zhengzhou 450002, China

-

Received:2023-05-19Online:2024-04-10Published:2024-04-18 -

Contact:ZHANG Fawen E-mail:12639479@qq.com;zhangfawen@henau.edu.cn

CLC Number:

Cite this article

YANG Bin, LI Yinyue, DONG Mingkun, HAN Ximeng, GUI Xin, ZHANG Fawen. Treatment effect and flocculation mechanism of abandoned drilling mud by different flocculants[J]. Inorganic Chemicals Industry, 2024, 56(4): 34-41.

share this article

| 1 | 中华人民共和国自然资源部. 全国石油天然气资源勘查开采通报(2020年度)[EB/OL].[ 2021-09-17]. . |

| 2 | 王彩林. 废弃钻井泥浆随钻无害化处理[D]. 天津: 天津工业大学, 2017. |

| WANG Cailin. Harmless treatment of waste drilling mud while drilling[D]. Tianjin: Tianjin Polytechnic University, 2017. | |

| 3 | 毛志新, 张太亮, 赵德银, 等. 煤层气聚合物钻井废液无害化处理研究[J]. 钻采工艺, 2012, 35(3):82-85,13. |

| MAO Zhixin, ZHANG Tailiang, ZHAO Deyin, et al. Research on non-hazardous treatment for coal-seam gas polymer waste drilling fluid[J]. Drilling & Production Technology, 2012, 35(3):82-85,13. | |

| 4 |

KHAZAIE A, MAZARJI M, SAMALI B, et al. A review on coagulation/flocculation in dewatering of coal slurry[J]. Water, 2022, 14(6):918.

doi: 10.3390/w14060918 |

| 5 | 杨双春, 佟双鱼, 李东胜, 等. 废弃钻井液无害化处理技术研究进展[J]. 应用化工, 2019, 48(12):3037-3041. |

| YANG Shuangchun, TONG Shuangyu, LI Dongsheng, et al. Research progress on harmless disposal technology of waste drilling fluid[J]. Applied Chemical Industry, 2019, 48(12):3037-3041. | |

| 6 | 梁止水, 杨才千, 高海鹰, 等. 建筑工程废弃泥浆快速泥水分离试验研究[J]. 东南大学学报(自然科学版), 2016, 46(2):427-433. |

| LIANG Zhishui, YANG Caiqian, GAO Haiying, et al. Experimental study on rapid separation between water and slurry from construction engineering[J]. Journal of Southeast University(Natural Science Edition), 2016, 46(2):427-433. | |

| 7 | 姚蒲. 工程废泥浆吸附特性及脱水方法研究[D]. 成都: 成都理工大学, 2019. |

| YAO Pu. Study on adsorption characteristics and dehydration method of engineering waste mud[D]. Chengdu: Chengdu University of Technology, 2019. | |

| 8 | 高宇, 周普玉, 杨霞, 等. 絮凝剂对工程废弃泥浆脱水性能的影响[J]. 环境工程学报, 2017, 11(10):5597-5602. |

| GAO Yu, ZHOU Puyu, YANG Xia, et al. Effect of flocculants on dehydration properties of construction waste slurry[J]. Chinese Journal of Environmental Engineering, 2017, 11(10):5597-5602. | |

| 9 | 郑怀礼, 高亚丽, 蔡璐微, 等. 聚合氯化铝混凝剂研究与发展状况[J]. 无机盐工业, 2015, 47(2):1-5. |

| ZHENG Huaili, GAO Yali, CAI Luwei, et al. Research and development status of poly aluminum chloride coagulant[J]. Inorganic Chemicals Industry, 2015, 47(2):1-5. | |

| 10 | 赵媛媛. 阳离子型聚丙烯酰胺的制备及絮凝性能研究[D]. 南宁: 广西大学, 2022. |

| ZHAO Yuanyuan. Synthesis and flocculation properties of cationic polyacrylamide[D]. Nanning: Guangxi University, 2022. | |

| 11 | 王玉飞, 王献杰, 许春馨, 等. 絮凝剂对钻井废液的无污染处理[J]. 当代化工, 2022, 51(8):1773-1777. |

| WANG Yufei, WANG Xianjie, XU Chunxin, et al. Non-pollution treatment of drilling waste fluid by flocculant[J]. Contemporary Chemical Industry, 2022, 51(8):1773-1777. | |

| 12 | 邱正松, 张现斌, 陶瑞东, 等. 一种钻井废液深度处理方法与工艺:中国,102139971A[P]. 2011-08-03. |

| 13 | 乔三原, 刘庆旺, 范振忠. 阳离子双子絮凝剂处理海水基钻井废液[J]. 油田化学, 2020, 37(4):721-725,729. |

| QIAO Sanyuan, LIU Qingwang, FAN Zhenzhong. Treatment of seawater based drilling waste water with cationic gemini treatment agent[J]. Oilfield Chemistry, 2020, 37(4):721-725,729. | |

| 14 |

LIU Yang, ZHANG Yuchen, XIE Tao, et al. The study of optimization of flocculation and destabilization technology of waste PEM drilling fluid in Bohai oilfield[J]. Frontiers in Energy Research, 2021, 9:796786.

doi: 10.3389/fenrg.2021.796786 |

| 15 |

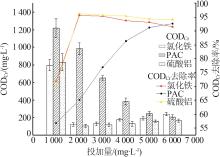

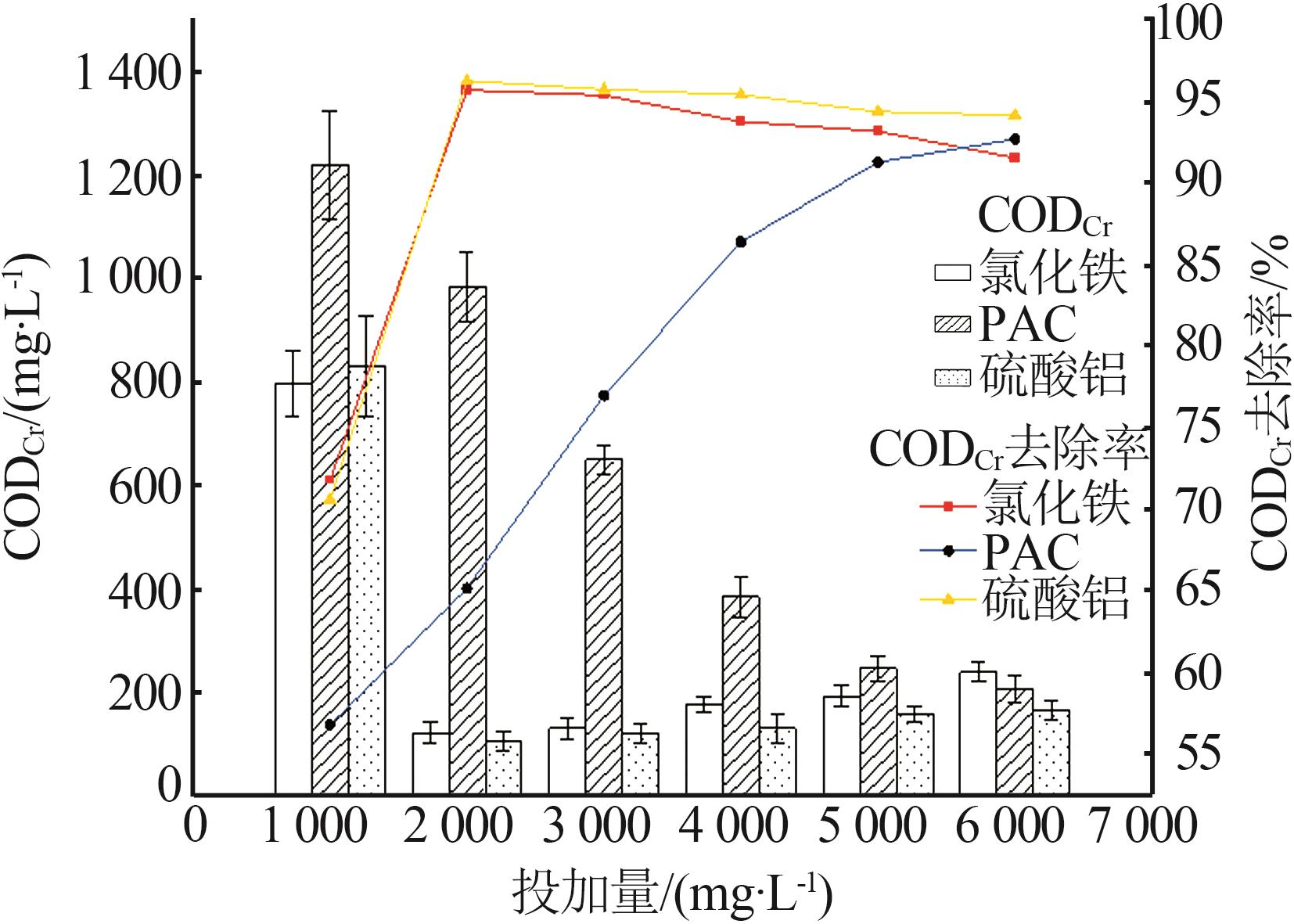

于冬冬, 钱雅洁, 刘保江, 等. 钻井泥浆废水混凝处理实验研究[J]. 工业水处理, 2020, 40(5):56-59.

doi: 10.11894/iwt.2019-0669 |

|

YU Dongdong, QIAN Yajie, LIU Baojiang, et al. Study on the coagulation treatment of drilling mud wastewater[J]. Industrial Water Treatment, 2020, 40(5):56-59.

doi: 10.11894/iwt.2019-0669 |

|

| 16 | 国家环境保护总局. 污水综合排放标准:GB 8978—1996[S]. 北京: 中国标准出版社, 1996. |

| 17 | 中华人民共和国环境保护部. 水质化学需氧量的测定重铬酸盐法:HJ 828—2017[S]. 北京: 中国环境出版社, 2017. |

| 18 | 国家环境保护局. 水质 悬浮物的测定 重量法:GB 11901—1989[S]. 北京: 中国标准出版社, 1990. |

| 19 | 国家环境保护局. 水质 色度的测定:GB 11903—1989[S]. 北京: 中国标准出版社, 1990. |

| 20 | 生态环境部. 水质 石油类和动植物油类的测定 红外分光光度法:HJ 637—2018[S]. 北京: 中国环境科学出版社, 2018. |

| 21 | 国家环境保护总局, 国家技术监督局. 固体废物 总铬的测定 二苯碳酰二肼分光光度法:GB/T 15555.5—1995[S]. 北京: 中国标准出版社, 1996. |

| 22 |

MUSTERE C P, MOROSANU I, CIOBANU R, et al. Assessment of coagulation-flocculation process efficiency for the natural organic matter removal in drinking water treatment[J]. Water, 2021, 13(21):3073.

doi: 10.3390/w13213073 |

| 23 | 罗伟. 钻井废弃泥浆固化路基材料性能研究[D]. 成都: 西南石油大学, 2015. |

| LUO Wei. Study on properties of subgrade material solidified by drilling waste mud[D]. Chengdu: Southwest Petroleum University, 2015. | |

| 24 | 王远英. 长庆油田胡尖山区压裂废液处理技术的研究与应用[D]. 西安: 西北大学, 2021. |

| WANG Yuanying. The research and application of fracturing wastewater treatment technology in Hujianshan area of Changqing Oilfield[D]. Xi 'an: Northwest University, 2021. | |

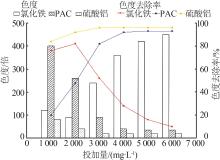

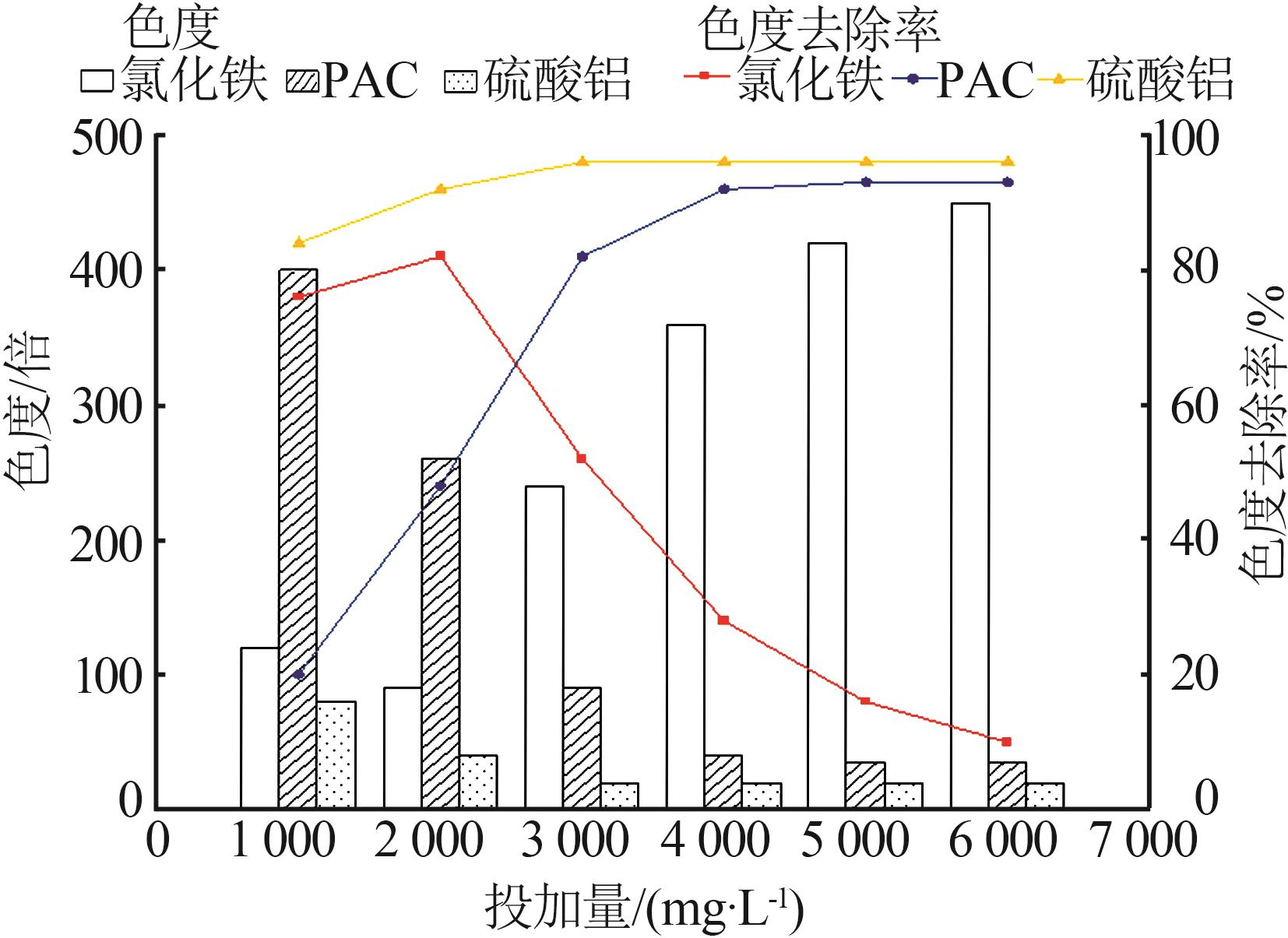

| 25 | 唐一鸣, 刘丹, 李启彬, 等. 硫酸铝混凝法处理页岩气钻井废水实验[J]. 水生态学杂志, 2020, 41(4):108-115. |

| TANG Yiming, LIU Dan, LI Qibin, et al. Treatment of polymer mud shale gas drilling wastewater by coagulation with Al2(SO4)3-PAM[J]. Journal of Hydroecology, 2020, 41(4):108-115. | |

| 26 | LIN Jieli, LI Jiesen. Reduction and resources treatment of construction waste slurry[J]. IOP Conference Series:Earth and Environmental Science, 2019, 233: 052055. |

| 27 |

YANG Peng, LI Dandan, ZHANG Weijun, et al. Flocculation-dewatering behavior of waste activated sludge particles under chemical conditioning with inorganic polymer flocculant:Effects of typical sludge properties[J]. Chemosphere, 2019, 218:930- 940.

doi: S0045-6535(18)32277-X pmid: 30609498 |

| 28 | 杨红梅, 谷晋川, 张德航, 等. PAC与PAM复合絮凝剂处理泡菜废水[J]. 土木建筑与环境工程, 2017, 39(4):95-101. |

| YANG Hongmei, GU Jinchuan, ZHANG Dehang, et al. Analysis of flocculant PAC and PAM in the treatment of pickled cabbage wastewater[J]. Journal of Civil,Architectural & Environmental Engineering, 2017, 39(4):95-101. | |

| 29 |

LI Bo, ZHAO Jianhai, GE Wenqi, et al. Coagulation-flocculation performance and floc properties for microplastics removal by magnesium hydroxide and PAM[J]. Journal of Environmental Chemical Engineering, 2022, 10(2):107263.

doi: 10.1016/j.jece.2022.107263 |

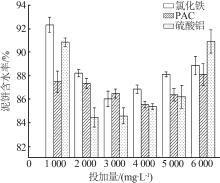

| 30 | 李春林, 吴言坤, 吕焕杰, 等. PAM类有机絮凝剂对高黏粒含量废弃泥浆脱水性能影响研究[J]. 隧道建设(中英文), 2022, 42(2):260-267. |

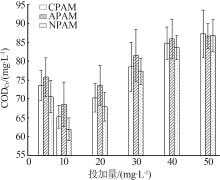

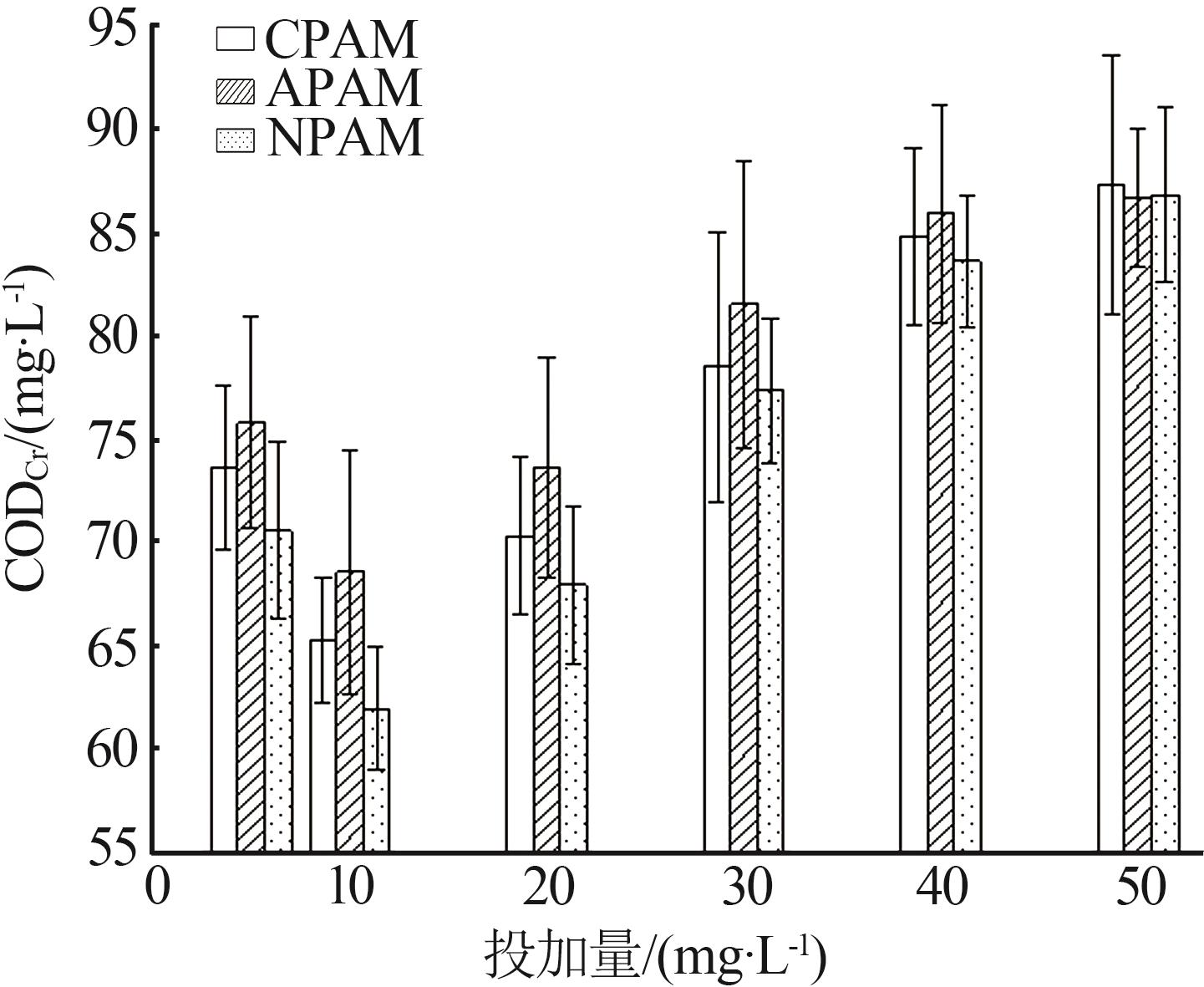

| LI Chunlin, WU Yankun, Huanjie LÜ, et al. Influence of polyacrylamide organic flocculant on dewatering performance of waste slurry with a high content of clay particles[J]. Tunnel Construction, 2022, 42(2):260-267. | |

| 31 |

AI Jing, WANG Zhiyue, DIONYSIOU D D, et al. Understanding synergistic mechanisms of ferrous iron activated sulfite oxidation and organic polymer flocculation for enhancing wastewater sludge dewaterability[J]. Water Research, 2021, 189:116652.

doi: 10.1016/j.watres.2020.116652 |

| 32 |

ZHANG Jingzhen, YUE Qinyan, XIA Chao, et al. The study of Na2SiO3 as conditioner used to deep dewater the urban sewage dewatered sludge by filter press[J]. Separation and Purification Technology, 2017, 174:331-337.

doi: 10.1016/j.seppur.2016.11.004 |

| 33 | DU C L, PENG M G, LI Z W, et al. Experimental study on the effect of C-PAM and A-PAM on dewatering performance of waste mud[J]. Journal of Physics:Conference Series, 2021, 2045(1): 012030. |

| 34 | 史志鹏. 非离子聚丙烯酰胺(NPAM)对絮凝体沉降特性的影响研究[D]. 杨凌: 西北农林科技大学, 2019. |

| SHI Zhipeng. Flocculation and sedimentation characteristics of flocs under the influence of nonionic polyacrylamide[D]. Yangling: Northwest A & F University, 2019. | |

| 35 | WANG Dongxing, DI Shengjie, WU Linfeng, et al. Sedimentation behavior of organic,inorganic,and composite flocculant-treated waste slurry from construction works[J]. Journal of Materials in Civil Engineering, 2021, 33(7): 04021134. |

| 36 | 梁效, 王勇海, 吴天骄, 等. 无机和有机絮凝剂复配对铁尾矿沉降特性研究[J]. 金属矿山, 2020(11):129-133. |

| LIANG Xiao, WANG Yonghai, WU Tianjiao, et al. Study on the settlement characteristics of iron tailings by combination of inorganic and organic flocculants[J]. Metal Mine, 2020(11):129- 133. | |

| 37 |

NGUYEN C V, NGUYEN A V, DOI A, et al. Advanced solid-liquid separation for dewatering fine coal tailings by combining chemical reagents and solid bowl centrifugation[J]. Separation and Purification Technology, 2021, 259:118172.

doi: 10.1016/j.seppur.2020.118172 |

| 38 | 王东星, 伍林峰, 唐弈锴, 等. 建筑废弃泥浆泥水分离过程与效果评价[J]. 浙江大学学报(工学版), 2020, 54(6):1049-1057. |

| WANG Dongxing, WU Linfeng, TANG Yikai, et al. Mud-water separation process and performance evaluation of waste slurry from construction engineering[J]. Journal of Zhejiang University (Engineering Science), 2020, 54(6):1049-1057. | |

| 39 |

ZENG Hua, TANG Honghu, SUN Wei, et al. Strengthening solid-liquid separation of bauxite residue through the synergy of charge neutralization and flocculation[J]. Separation and Purification Technology, 2022, 285:120296.

doi: 10.1016/j.seppur.2021.120296 |

| 40 |

WANG Houfeng, HU Hao, WANG Huajie, et al. Combined use of inorganic coagulants and cationic polyacrylamide for enhancing dewaterability of sewage sludge[J]. Journal of Cleaner Production, 2019, 211:387-395.

doi: 10.1016/j.jclepro.2018.11.208 |

| 41 | OVENDEN C, XIAO Huining. Flocculation behaviour and mechanisms of cationic inorganic microparticle/polymer systems[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2002, 197(1/2/3):225-234. |

| 42 |

TANG Xiaomin, WANG Honghua, XIANG Zhaobao, et al. Flocculation performance enhancement of organic polymer flocculants via adjusting cationic block length:Molecular structure and characteristics[J]. Chemical Engineering Research and Design, 2022, 181:253-265.

doi: 10.1016/j.cherd.2022.03.036 |

| 43 | 夏新星, 陈文峰, 王龙涛. 复合调理剂对废弃建筑泥浆脱水性能的影响[J]. 环境工程学报, 2022, 16(4):1313-1322. |

| XIA Xinxing, CHEN Wenfeng, WANG Longtao. Effect of composite conditioner on dewatering performance of high alkaline construction slurry[J]. Chinese Journal of Environmental Engineering, 2022, 16(4):1313-1322. |

| [1] | WANG Lijuan, YAN Kezhou, GUO Zhiqiang, ZHAO Zhonghe, GUO Yanxia, CHENG Fangqin. Preparation of poly-aluminum chloride from acid leaching liquor of red mud-coal gangue activated by sodium salt [J]. Inorganic Chemicals Industry, 2023, 55(4): 76-83. |

| [2] | LI Xiaoqi,SUN Yongjun,CHEN Aowen,YU Yuanyuan,SUN Wenquan,ZHOU Jun. Study on preparation of magnetic heavy metal capture flocculant [J]. Inorganic Chemicals Industry, 2022, 54(2): 81-84. |

| [3] | YANG Tie-Jian, YAN Xin. Research on CPAM coagu-flocculation mechanism in brine purification process [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(6): 32-. |

| [4] | LIAO Pan, CHEN Xue-An, CHANG Xin-An, XIAO Wei-Qiang, WANG Shao-Hua. Study on removal of silicon and preparation of high purity ferric oxide red from acid leaching filtrate of tailings [J]. INORGANICCHEMICALSINDUSTRY, 2012, 44(7): 41-. |

| [5] | Yang Mingping;Hu Zhongyu. Preparation of polysilicate polyferric chloride flocculant (PSPFC)by leaching ferric tailings with hydrochloric acid pickling wastewater [J]. INORGANICCHEMICALSINDUSTRY, 2008, 0(4): 0-0. |

| [6] | Liu Houfan;Pan Qinghui;Zhou Xinmu;Xia Guoqiang;Gao Changhua. Study on arsenic removal in the preparation of feed grade zinc oxide by ammonia-ammonium sulfate method [J]. INORGANICCHEMICALSINDUSTRY, 2008, 0(3): 0-0. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||