| 1 |

郑绍聪,宁平,汪帆,等.磷石膏热分解制备二氧化硫和氧化钙研究[J].无机盐工业,2013,45(9):45-47.

|

|

ZHENG Shaocong, NING Ping, WANG Fan,et al.Study on preparation of sulfur dioxide and lime by thermal decomposition of phosphogypsum[J].Inorganic Chemicals Industry,2013,45(9):45-47.

|

| 2 |

崔荣政,白海丹,高永峰,等.磷石膏综合利用现状及“十四五”发展趋势[J].无机盐工业,2022,54(4):1-4.

|

|

CUI Rongzheng, BAI Haidan, GAO Yongfeng,et al.Current situation of comprehensive utilization of phosphogypsum and its development trend of 14th Five-Year Plan[J].Inorganic Chemicals Industry,2022,54(4):1-4.

|

| 3 |

杜明霞,王进明,董发勤,等.磷石膏资源化利用研究进展[J].矿产保护与利用,2020,40(3):121-126.

|

|

DU Mingxia, WANG Jinming, DONG Faqin,et al.Research progress on resource utilization of phosphogypsum[J].Conservation and Utilization of Mineral Resources,2020,40(3):121-126.

|

| 4 |

李纯,薛鹏丽,张文静,等.我国磷石膏处置现状及绿色发展对策[J].化工环保,2021,41(1):102-106.

|

|

LI Chun, XUE Pengli, ZHANG Wenjing,et al.Disposal status of phosphogypsum in China and countermeasures for green development[J].Environmental Protection of Chemical Industry,2021,41(1):102-106.

|

| 5 |

谷守玉,苗俊艳,侯翠红,等.磷石膏综合利用途径及关键共性技术创新研究建议[J].矿产保护与利用,2020,40(3):115-120.

|

|

GU Shouyu, MIAO Junyan, HOU Cuihong,et al.Comprehensive utilization of phosphogypsum and research suggestions on key common technology innovation[J].Conservation and Utilization of Mineral Resources,2020,40(3):115-120.

|

| 6 |

LI Beixing, LI Long, CHEN Xiao,et al.Modification of phosphogypsum using circulating fluidized bed fly ash and carbide slag for use as cement retarder[J].Construction and Building Materials,2022,338:127630.

|

| 7 |

熊春杨,吕淑珍,牛云辉,等.四川某地磷石膏制备建筑石膏及其性能研究[J].非金属矿,2020,43(3):33-36.

|

|

XIONG Chunyang, Shuzhen LÜ, NIU Yunhui,et al.Preparation of building gypsum from phosphogypsum in Sichuan and its properties[J].Non-Metallic Mines,2020,43(3):33-36.

|

| 8 |

张峻,解维闵,董雄波,等.磷石膏材料化综合利用研究进展[J].材料导报,2023,37(16):167-178.

|

|

ZHANG Jun, XIE Weimin, DONG Xiongbo,et al.Research progress on comprehensive utilization of phosphogypsum for materials:A review[J].Materials Reports,2023,37(16):167-178.

|

| 9 |

高强.“双碳”背景下磷石膏制硫酸联产水泥技术面临的机遇与挑战及发展建议[J].磷肥与复肥,2023,38(3):25-28.

|

|

GAO Qiang.Opportunities,challenges and development suggestions of co-production of sulfuric acid and cement from phosphogypsum under the background of “double carbon”[J].Phosphate & Compound Fertilizer,2023,38(3):25-28.

|

| 10 |

FENG Yuan, XUE Zixin, ZHANG Baifa,et al.Effects of phosphogypsum substitution on the performance of ground granulated blast furnace slag/fly ash-based alkali-activated binders[J].Journal of Building Engineering,2023,70:106387.

|

| 11 |

LIN Yan, SUN Hongjuan, PENG Tongjiang,et al.A simple and efficient method for preparing high-purity α-CaSO4·0.5H2O whiskers with phosphogypsum[J].Materials,2022,15(11):4028.

|

| 12 |

刘月,杨树青,张万锋,等.磷石膏和碱蓬对盐渍化土壤水盐及细菌群落结构的影响[J].环境科学,2023,44(4):2325-2337.

|

|

LIU Yue, YANG Shuqing, ZHANG Wanfeng,et al.Effects of phosphogypsum and suaeda salsa on the soil moisture,salt,and bacterial community structure of salinized soil[J].Environmental Science,2023,44(4):2325-2337.

|

| 13 |

兰文涛.半水磷石膏基矿用复合充填材料及其管输特性研究[D].北京:北京科技大学,2019.

|

| 14 |

SUN Jian, LIU Wenqiang, WANG Wenyu,et al.Optimizing synergy between phosphogypsum disposal and cement plant CO2

|

|

capture by the calcium looping process[J].Energy & Fuels,2016.Doi:10.1021/acs.energyfuels.5b02786 .

|

| 15 |

COSTA R P, DE MEDEIROS M H G, RODRIGUEZ MARTINEZ E D,et al.Effect of soluble phosphate,fluoride,and pH in Brazilian phosphogypsum used as setting retarder on Portland cement hydration[J].Case Studies in Construction Materials,2022,17:e01413.

|

| 16 |

余苏,李建锡,马丽萍,等.磷石膏分解特性对磷石膏制硫酸联产水泥新工艺的影响研究[J].昆明理工大学学报(理工版),2010,35(4):80-84.

|

|

YU Su, LI Jianxi, MA Liping,et al.Thermal effects of phosphogypsum on co-production of acid and cement[J].Journal of Kunming University of Science and Technology(Science and Technology),2010,35(4):80-84.

|

| 17 |

马丽萍.磷石膏资源化综合利用现状及思考[J].磷肥与复肥,2019,34(7):5-9.

|

|

MA Liping.Current situation and consideration of comprehensive utilization of phosphogypsum resources[J].Phosphate & Compound Fertilizer,2019,34(7):5-9.

|

| 18 |

YING Guoliang, ZHOU Mingkai, LI Beixing.Experimental studies and technology process on phosphor-gypsum decomposition for producing sulfuric acid and lime[J].Applied Mechanics and Materials,2011,69:103-107.

|

| 19 |

XU Yue, LI Jianxi, KAN Lili.Investigation on a new hydraulic cementitious binder made from phosphogypsum[J].Advanced Materials Research,2013,864-867:1923-1928.

|

| 20 |

陈肖虎,庄昌凌,王家伟,等.一种磷石膏和粉煤灰制酸联产橡塑阻燃剂的方法:中国,108976503A[P].2018-12-11.

|

| 21 |

张晖,屈凌波,侯翠红,等.高杂质磷石膏制硫酸联产矿渣棉纤维的方法:中国,113753864B[P].2023-06-02.

|

| 22 |

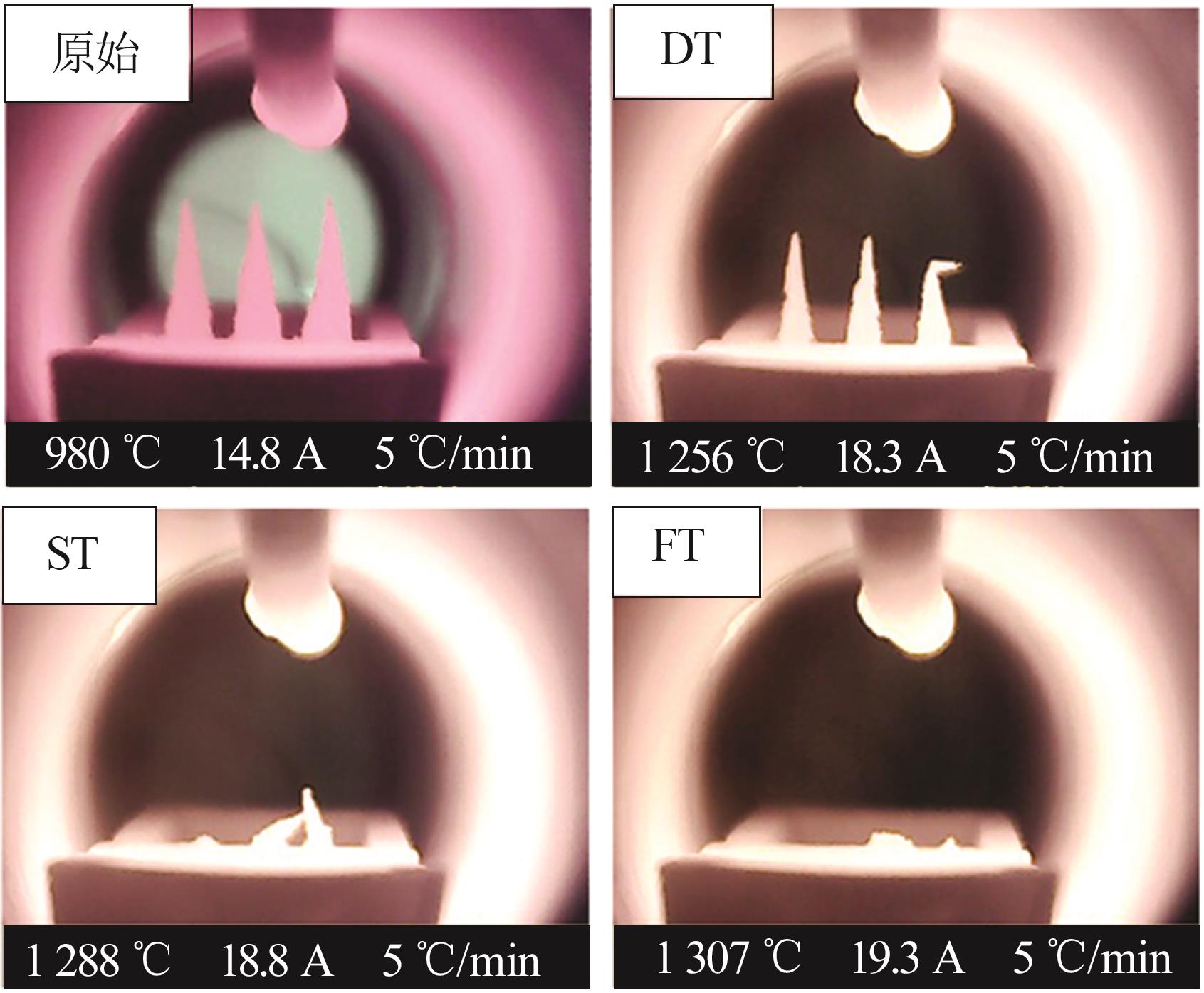

DU Peipei, LONG Yue, ZHANG Yuzhu,et al.Influence of fly ash on the fluidity of blast furnace slag for the preparation of slag wool[J].Crystals,2023,13(1):119.

|

| 23 |

姚建新,边妙莲.粉煤灰对矿渣棉用调质高炉渣析晶性能的影响[J].科学技术与工程,2019,19(36):388-393.

|

|

YAO Jianxin, BIAN Miaolian.Effect of fly ash on crystallization properties of modified blast furnace slag for preparing slag cott-on[J].Science Technology and Engineering,2019,19(36):388-393.

|

| 24 |

李智慧,张玉柱,龙跃,等.调质熔渣制备矿渣棉及棉板的中试研究[J].材料与冶金学报,2017,16(1):63-67.

|

|

LI Zhihui, ZHANG Yuzhu, LONG Yue,et al.Pilot-scale research on slag wool and cotton board prepared by quenched slag[J].Journal of Materials and Metallurgy,2017,16(1):63-67.

|

| 25 |

师存兰,邢宏伟,吴金虎.高炉渣制备矿渣棉及其保温板的工艺概述[J].河北冶金,2021(11):10-13,73.

|

|

SHI Cunlan, XING Hongwei, WU Jinhu.Process overview of preparation of slag wool and its insulation board from blast furnace slag[J].Hebei Metallurgy,2021(11):10-13,73.

|

| 26 |

李杰,张玉柱,刘卫星,等.高炉渣调质作为矿渣纤维原料[J].环境工程学报,2013,7(12):4971-4977.

|

|

LI Jie, ZHANG Yuzhu, LIU Weixing,et al.Quenched and tempered blast furnace slag as slag fiber raw materials[J].Chinese Journal of Environmental Engineering,2013,7(12):4971-4977.

|

| 27 |

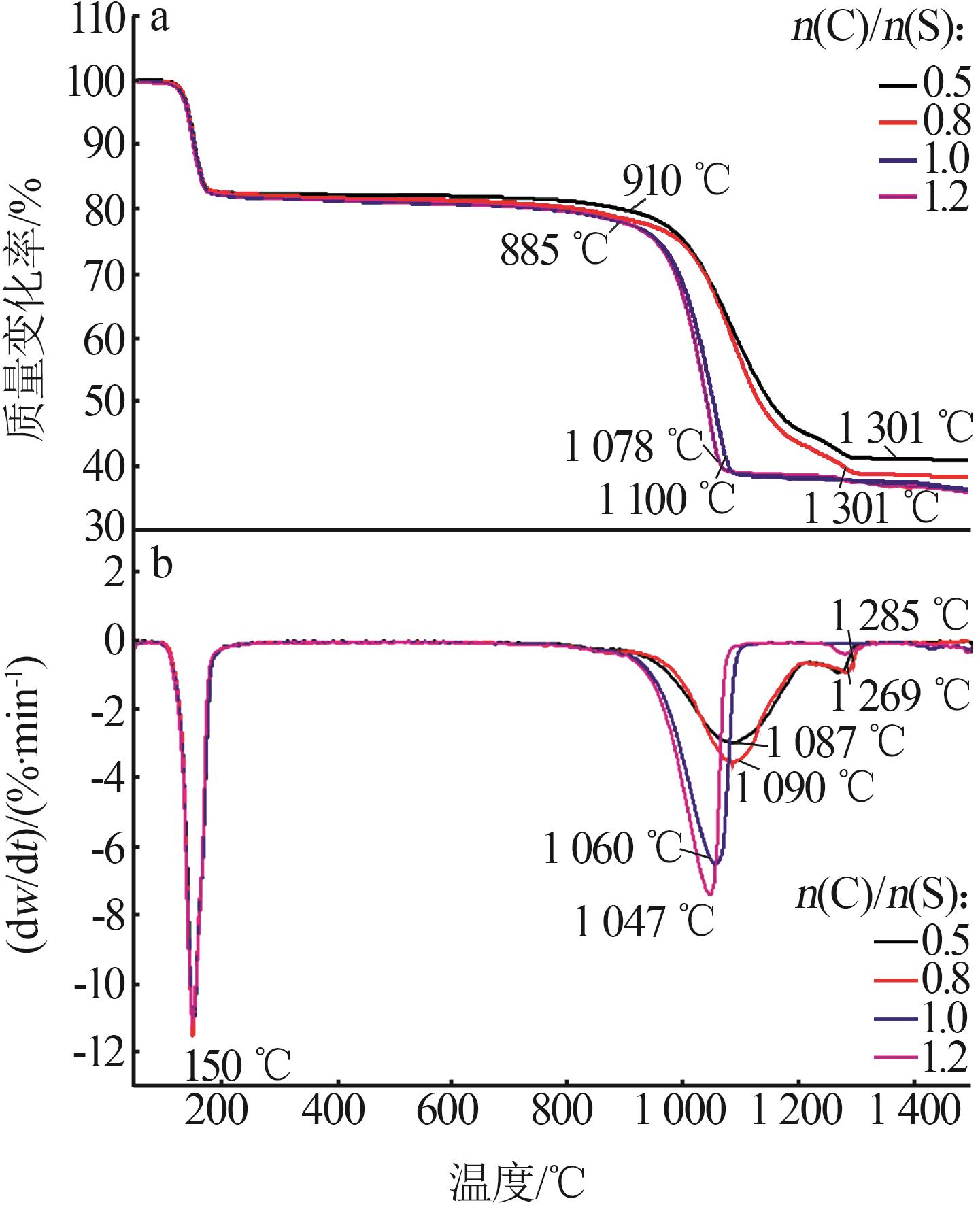

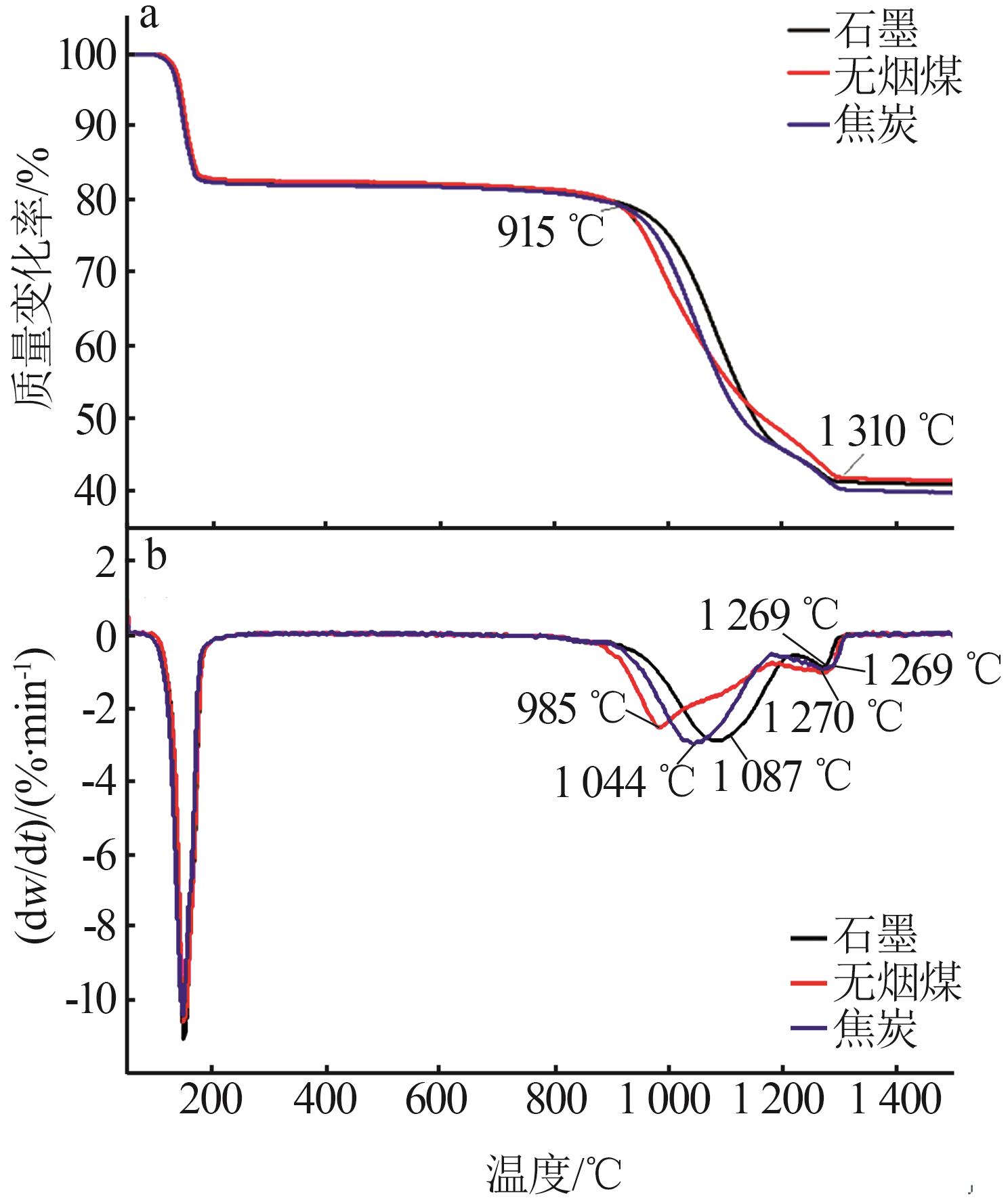

燕春培,郁青春,刘大春,等.真空碳热还原分解硫酸钙热力学分析及实验探究[J].真空科学与技术学报,2014,34(5):517-521.

|

|

YAN Chunpei, YU Qingchun, LIU Dachun,et al.Decomposition of calcium sulphate by carbothermic reduction at reduced pressures[J].Chinese Journal of Vacuum Science and Technology,2014,34(5):517-521.

|

| 28 |

苏航,左海滨,赵骏.石膏在高温下的分解脱硫研究[J].无机盐工业,2019,51(7):68-73.

|

|

SU Hang, ZUO Haibin, ZHAO Jun.Desulphurization of gypsum at high temperature[J].Inorganic Chemicals Industry,2019,51(7):68-73.

|

| 29 |

张云鹏,杨勤勤,刘永卓,等.CO2气氛下褐煤还原磷石膏的TG-FTIR研究[J].高校化学工程学报,2016,30(3):611-617.

|

|

ZHANG Yunpeng, YANG Qinqin, LIU Yongzhuo,et al.TG-FTIR study on phosphogypsum reduction with lignite under CO2 atmosphere[J].Journal of Chemical Engineering of Chinese Universities,2016,30(3):611-617.

|

| 30 |

肖海平,周俊虎,曹欣玉,等.CaSO4在不同气氛下分解特性的实验研究[J].动力工程,2004,24(6):889-892.

|

|

XIAO Haiping, ZHOU Junhu, CAO Xinyu,et al.Experimental study of decomosition behavior of CaSO4 in different atmospher-es[J].Power Engineering,2004,24(6):889-892.

|

| 31 |

宋世林.岩棉与矿渣棉性能差异研究[J].非金属矿,2001, 24(1):11-12,14.

|

|

SONG Shilin.Study on performance difference between rock wool and slag wool[J].Non-Metallic Mines,2001,24(1):11-12,14.

|

| 32 |

张伟,宁平,马丽萍,等.循环流化床中高硫煤还原分解磷石膏中试研究[J].现代化工,2009,29(1):78-81.

|

|

ZHANG Wei, NING Ping, MA Liping,et al.Pilot study on reductive decomposition of phosphogypsum with high sulfur coal in a circulating fluidized bed[J].Modern Chemical Industry,2009,29(1):78-81.

|

| 33 |

罗昌达.无烟煤代替焦炭作还原剂生产黄磷[J].贵州化工,1994,19(3):20-22.

|

|

LUO Changda.Production of yellow phosphorus by anthracite instead of coke as reducing agent[J].Guizhou Chemical Industry,1994,19(3):20-22.

|

), GU Shouyu1, HOU Cuihong1(

), GU Shouyu1, HOU Cuihong1( ), JING Hongquan1, GUAN Hongling1, ZHANG Hui2

), JING Hongquan1, GUAN Hongling1, ZHANG Hui2