| 1 |

郑建国,于南树,刘永秀,等.磷酸活化磷尾矿制取聚合态钙镁磷肥的工艺条件研究[J].无机盐工业,2020,52(2):43-46.

|

|

ZHENG Jianguo, YU Nanshu, LIU Yongxiu,et al.Study on technological conditions of polymeric calcium magnesium phosphate fertilizer from phosphoric acid activated phosphate tailings[J].Inorganic Chemicals Industry,2020,52(2):43-46.

|

| 2 |

张汉泉,许鑫,胡超杰,等.磷化工固体废弃物综合利用技术现状[J].中国矿业,2021,30(4):50-55,63.

|

|

ZHANG Hanquan, XU Xin, HU Chaojie,et al.Current situation of comprehensive utilization technology of solid waste of phosphorus chemical[J].China Mining Magazine,2021,30(4):50-55,63.

|

| 3 |

吴发富,王建雄,刘江涛,等.磷矿的分布、特征与开发现状[J].中国地质,2021,48(1):82-101.

|

|

WU Fafu, WANG Jianxiong, LIU Jiangtao,et al.Distribution,geology and development status of phosphate resources[J].Geology in China,2021,48(1):82-101.

|

| 4 |

杨成.磷尾矿的综合利用试验研究[D].武汉:武汉工程大学,2018.

|

|

YANG Cheng.Study on the comprehensive utilization of phosphate tailings[D].Wuhan:Wuhan Institute of Technology,2018.

|

| 5 |

ABDEL-HAKEEM M, EL-HABAAK G.The potential production of rock-based fertilizer and soil conditioner from phosphate mine wastes:A case study from Abu-Tartur Plateau in the Western Desert of Egypt[J].Journal of Cleaner Production,2021,329:129761.

|

| 6 |

ARROUG L, ELAATMANI M, ZEGZOUTI A,et al.Low-grade phosphate tailings beneficiation via organic acid leaching:Process optimization and kinetic studies[J].Minerals,2021,11(5):492.

|

| 7 |

颜鑫,魏义兰.含钙镁废渣综合利用的现状及展望[J].无机盐工业,2022,54(1):7-11.

|

|

YAN Xin, WEI Yilan.Present situation and prospect of comprehensive utilization of waste residue containing calcium and magnesium[J].Inorganic Chemicals Industry,2022,54(1):7-11.

|

| 8 |

周雪娜,关洪亮,何东升,等.磷尾矿综合利用研究进展[J].广州化工,2021,49(5):24-27.

|

|

ZHOU Xuena, GUAN Hongliang, HE Dongsheng,et al.Research progress on comprehensive utilization by phosphate tailings[J].Guangzhou Chemical Industry,2021,49(5):24-27.

|

| 9 |

黄洋,叶义成,胡南燕,等.磷尾矿材料化综合利用途径研究进展[J].材料导报,2021,35(S2):279-284,293.

|

|

HUANG Yang, YE Yicheng, HU Nanyan,et al.Research progress in materialized utilization of phosphate tailings[J].Materials Reports,2021,35(S2):279-284,293.

|

| 10 |

苗俊艳,王艳语,许秀成.中低品位磷矿及磷尾矿的综合利用现状[J].硫磷设计与粉体工程,2019(6):11-13,27,4.

|

|

MIAO Junyan, WANG Yanyu, XU Xiucheng.Current utilization of medium-and low-grade phosphate ore and tailing[J].Sulphur Phosphorus & Bulk Materials Handling Related Engineering,2019(6):11-13,27,4.

|

| 11 |

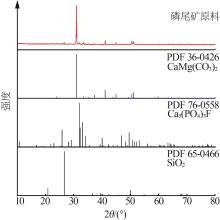

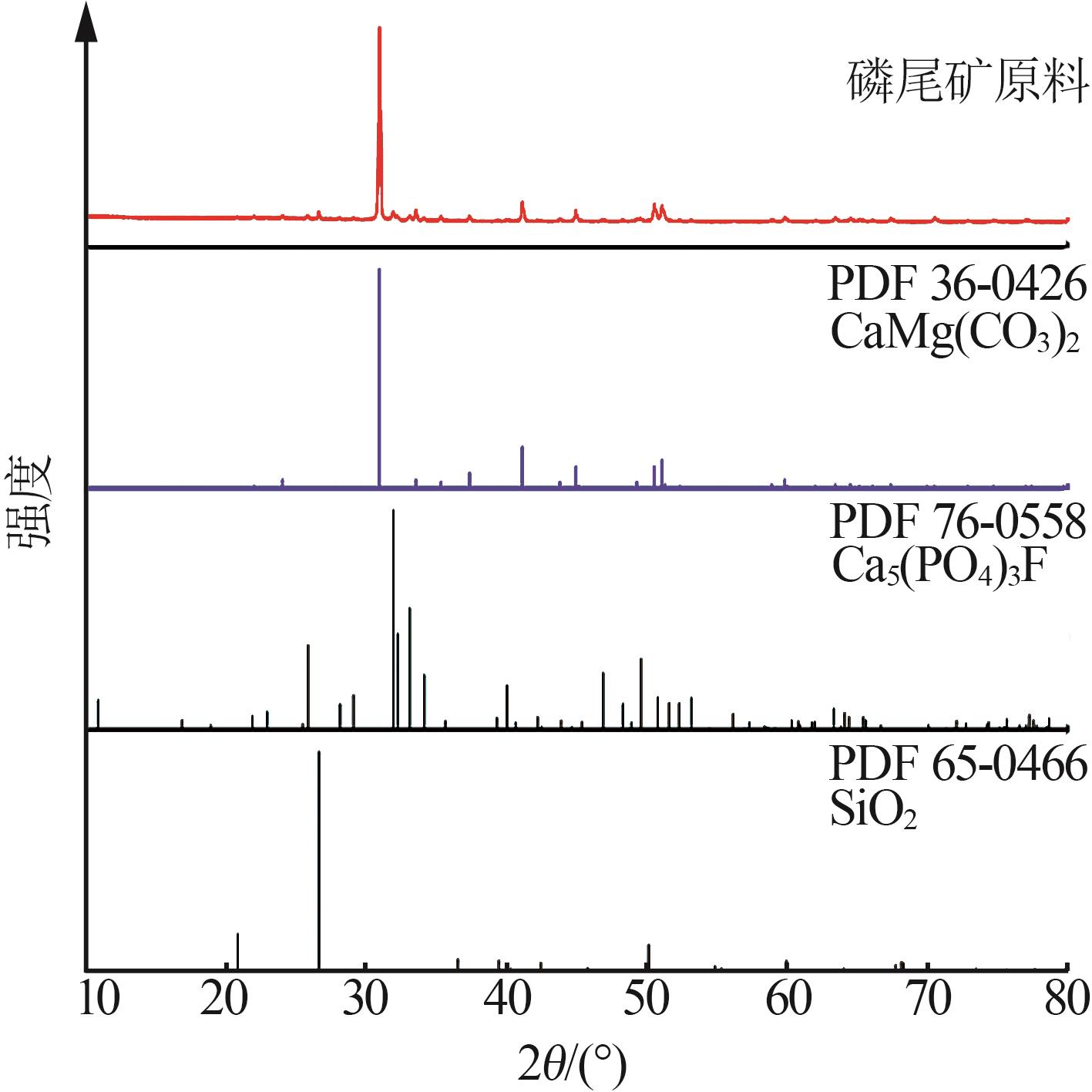

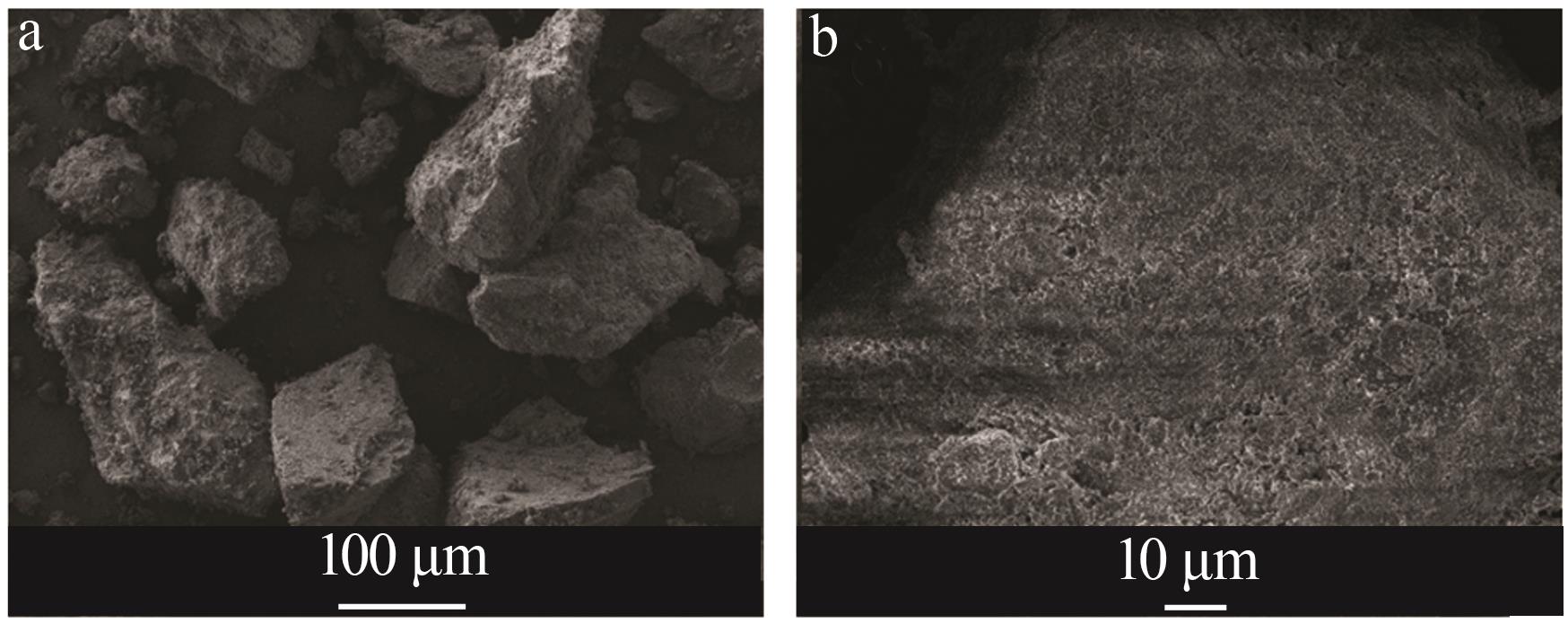

周佳琦,陈葵,武斌,等.磷尾矿煅烧及酸浸过程动力学研究[J].无机盐工业,2022,54(1):77-82,108.

|

|

ZHOU Jiaqi, CHEN Kui, WU Bin,et al.Study on kinetics of phosphate tailings calcination and acid leaching process[J].Inorganic Chemicals Industry,2022,54(1):77-82,108.

|

| 12 |

王东东.赤泥质缓蚀型融雪剂的制备及其性能研究[D].哈尔滨:黑龙江大学,2019.

|

|

WANG Dongdong.Study on preparation and properties of red mud corrosion-inhibiting snowmelt agent[D].Harbin:Heilongjiang University,2019.

|

| 13 |

夏伟.膜萃取稀醋酸废水生产醋酸钙镁盐的研究[D].大连:大连理工大学,2008.

|

|

XIA Wei.Study on producing calcium magnesium acetate from acetic acid wastewater via membrane extraction[D].Dalian:Dalian University of Technology,2008.

|

| 14 |

薛玉婷,孙衍忠,周斌.环保型融雪剂新工艺及产品性能研究[J].化工管理,2020(27):61-62.

|

| 15 |

韩爱霞,吕海棠,王兆谦,等.乳清两步发酵法制取环保型融雪剂醋酸钙镁盐[J].无机盐工业,2012,44(2):48-50.

|

|

HAN Aixia, Haitang LÜ, WANG Zhaoqian,et al.Production of environment friendly deicer calcium magnesium acetate by two-stage fermentation process from cheese whey[J].Inorganic Che-

|

|

Industry micals,2012,44(2):48-50.

|

| 16 |

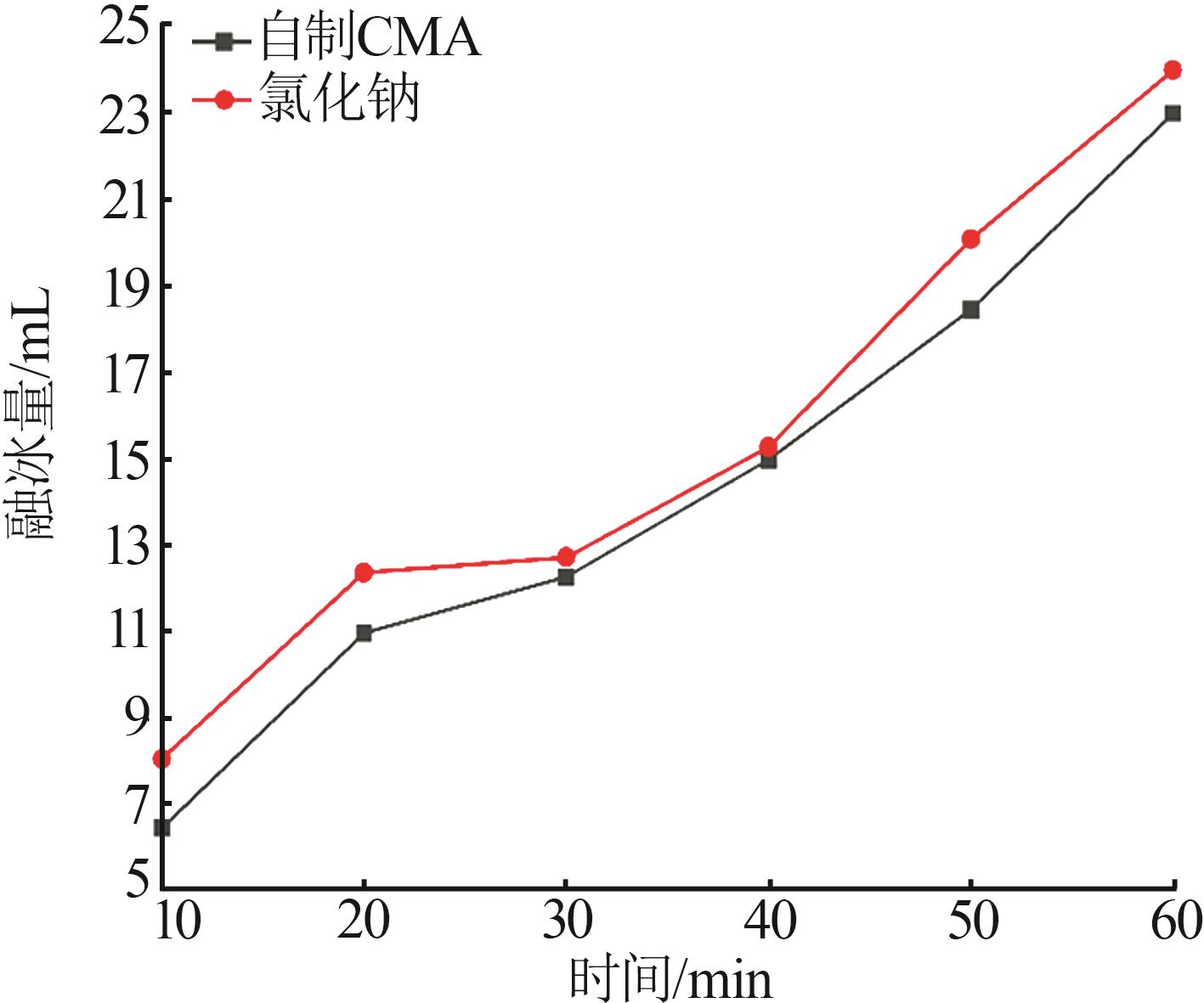

王腾,郭德栋,周小鹏,等.道路融雪剂融冰能力试验方法的改进研究[J].中外公路,2020,40(2):195-198.

|

|

WANG Teng, GUO Dedong, ZHOU Xiaopeng,et al.Research on test method improvement for deicing ability of road snow-melting agent[J].Journal of China & Foreign Highway,2020,40(2):195-198.

|

| 17 |

景金华,何冰.道路融雪剂性能评价方法对比研究[J].市政技术,2022,40(7):51-56.

|

|

JING Jinhua, HE Bing.Comparative study on evaluation methods for snowmelt agent performance[J].Journal of Municipal Technology,2022,40(7):51-56.

|

), TANG Jianwei1,2,4, LIU Yong2,3, HUA Quanxian2,3, LIU Pengfei1,2,4, WANG Baoming1,2,4(

), TANG Jianwei1,2,4, LIU Yong2,3, HUA Quanxian2,3, LIU Pengfei1,2,4, WANG Baoming1,2,4( )

)