| 1 |

林如山,何辉,唐洪彬,等.我国乏燃料干法后处理技术研究现状与发展[J].原子能科学技术,2020,54(S1):115-125.

|

|

LIN Rushan, HE Hui, TANG Hongbin,et al.Progress and development of dry reprocessing technology of spent fuel in China[J].Atomic Energy Science and Technology,2020,54(S1):115-125.

|

| 2 |

张磊,林如山,陈辉,等.NaCl-KCl熔盐体系电解制备金属铈工艺研究[J].原子能科学技术,2020,54(12):2306-2313.

|

|

ZHANG Lei, LIN Rushan, CHEN Hui,et al.Electrolytic extraction of Ce from NaCl-KCl molten salt[J].Atomic Energy Science and Technology,2020,54(12):2306-2313.

|

| 3 |

张磊,王有群,谢书宝,等.LiCl-KCl、NaCl-KCl和KCl熔盐体系中Ce(Ⅲ)的电化学行为[J].核化学与放射化学,2021,43(5):379-386.

|

|

ZHANG Lei, WANG Youqun, XIE Shubao,et al.Electrochemical behavior of Ce(Ⅲ) in LiCl-KCl,NaCl-KCl and KCl molten salt[J].Journal of Nuclear and Radiochemistry,2021,43(5):379-386.

|

| 4 |

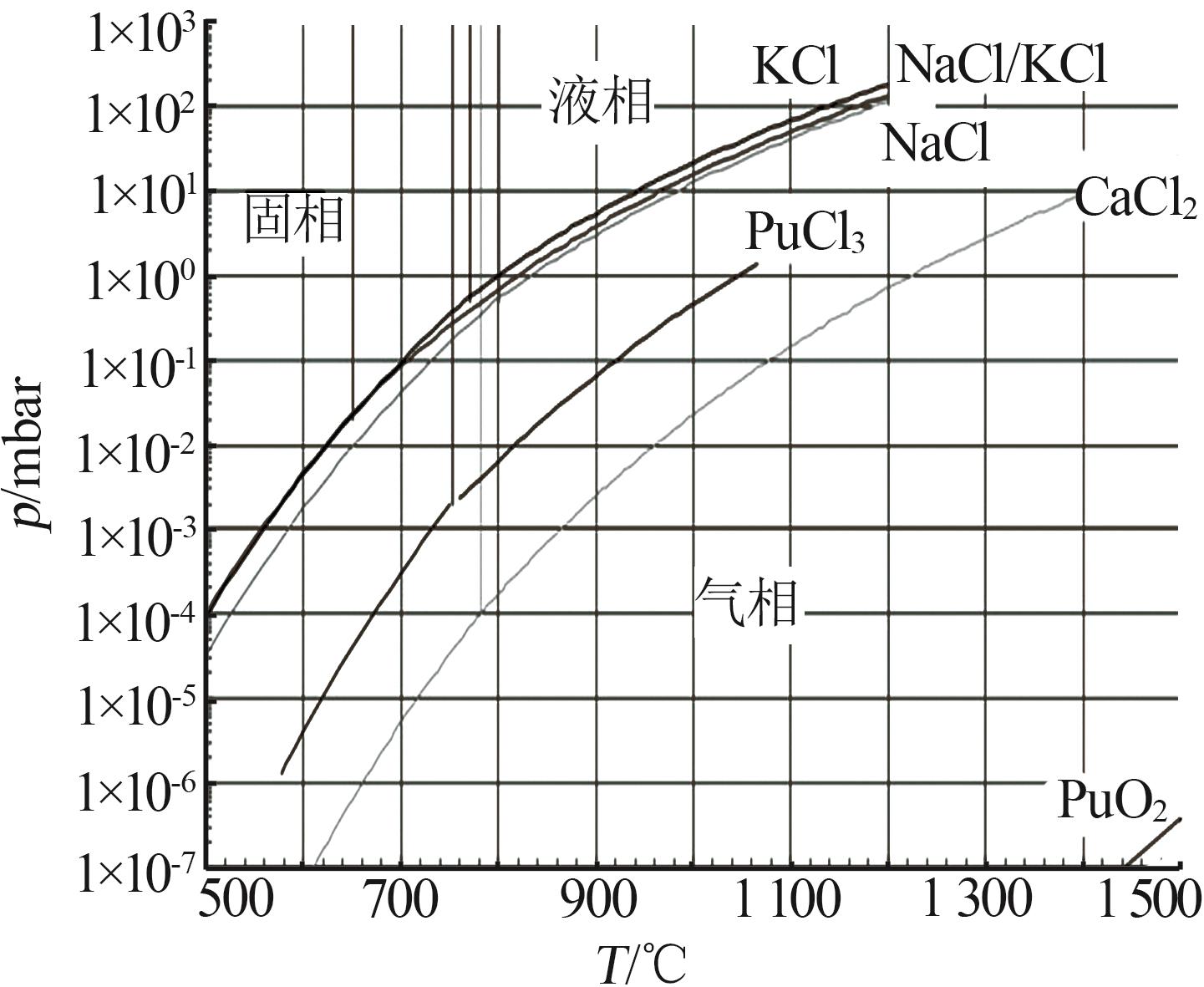

GARCIA E.High-temperature vacuum distillation separation of plutonium waste salts[C]∥Gaithersburg,MD:Efficient Separations and Processing Crosscuting Program 1996 Technical Exchange Meeting,1996:21-23.

|

| 5 |

REICHLEY-YINGER L, VANDEGRIFT G F.Recovery of plutonium and americium from chloride salt wastes by solvent extraction[J].Separation Science and Technology,1988,23(12/13):1409-1421.

|

| 6 |

MUSCATELLO A C, NAVRATIL J D.Chloride anion exchange process for DOR and ER residue salts[R].Pittsburgh,PA:Rockwell International Corp.,1986.

|

| 7 |

SMITH W H, WEDMA D E.Electrodialysis reduces waste in the treatment of pyrochemical salt residues[J].The Actinide Research Quarterly,1996,3:4-5.

|

| 8 |

CHRISTENSEN D C, WILLIAMS J D, MCNEESE J A,et al.Plutonium metal preparation and purification at Los Alamos-1984[R].

|

|

Los Alamos,NM:Los Alamos National Laboratory,1984.

|

| 9 |

FIFE K W, WEST M H.Pyrochemical investigations into recovering plutonium from americium extraction salt residues[R].Los Alamos,NM:Los Alamos National Laboratory,1987.

|

| 10 |

BOURGÈS G, FAURE S, FIERS B,et al.Vacuum distillation of plutonium pyrochemical salts[J].Procedia Chemistry,2012,7:731-739.

|

| 11 |

CHO Y J, YANG H C, EUN H C,et al.Characteristics of oxidation reaction of rare-earth chlorides for precipitation in LiCl-KCl molten salt by oxygen sparging[J].Journal of Nuclear Science and Technology,2006,43(10):1280-1286.

|

| 12 |

EUN H C, YANG H C, CHO Y J,et al.Separation of pure LiCl-KCl eutectic salt from a mixture of LiCl-KCl eutectic salt and rare-earth precipitates by vacuum distillation[J].Journal of Nu-

|

|

clear Science and Technology,2007,44(10):1295-1300.

|

| 13 |

耿俊霞,窦强,王子豪,等.钍基熔盐堆核能系统中熔盐的蒸馏纯化与分离[J].核化学与放射化学,2017,39(1):36-42.

|

|

GENG Junxia, DOU Qiang, WANG Zihao,et al.Purification and separation of fluoride molten salt in thorium molten salt reactors system by low pressure distillation[J].Journal of Nuclear and Radiochemistry,2017,39(1):36-42.

|

| 14 |

郑小强,窦强,程明,等.减压蒸馏法对熔盐堆载体盐中氧的去除研究[J].核技术,2022,45(4):46-52.

|

|

ZHENG Xiaoqiang, DOU Qiang, CHENG Ming,et al.Study on removal of oxide from carrier salt in molten salt reactor by vacuum distillation[J].Nuclear Techniques,2022,45(4):46-52.

|

| 15 |

杨甜宏,罗艳,付海英,等.氟化物对LiCl-KCl熔盐蒸馏行为的影响[J].核技术,2018,41(12):35-40.

|

|

YANG Tianhong, LUO Yan, FU Haiying,et al.The influence of fluorides on the distillation behaviors of molten LiCl-KCl[J].Nuclear Techniques,2018,41(12):35-40.

|

| 16 |

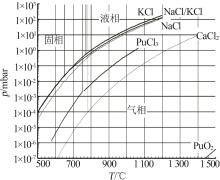

付海英,耿俊霞,杨洋,等.乏燃料干法后处理中的熔盐减压蒸馏技术[J].核技术,2018,41(4):5-12.

|

|

FU Haiying, GENG Junxia, YANG Yang,et al.Low pressure distillation technology of molten salt in spent fuel pyroprocessing field[J].Nuclear Techniques,2018,41(4):5-12.

|

| 17 |

GENG Junxia, LUO Yan, FU Haiying,et al.Temperature and pressure effect on evaporation behavior of chloride salts using low pressure distillation[J].Progress in Nuclear Energy,2022,147:104212.

|

| 18 |

赖耀斌,徐建兵,李忠岐,等.真空蒸馏法综合回收稀土熔盐电解渣工艺研究[J].真空科学与技术学报,2021,41(4):332-335.

|

|

LAI Yaobin, XU Jianbing, LI Zhongqi,et al.Research on comprehensive recovery of rare earth electrolytic molten salt slag by vacuum distillation[J].Chinese Journal of Vacuum Science and Technology,2021,41(4):332-335.

|

), JIA Yanhong1, DOU Qiang2, YANG Yang2

), JIA Yanhong1, DOU Qiang2, YANG Yang2