| 1 |

WANG Zhentao, DONG Kai, TIAN Lin,et al.Numerical analyses of sulfur dioxide transport by an atmospheric circulating drop[J].Atmospheric Pollution Research,2019,10(3):759-767.

|

| 2 |

杜晓燕,龙红明,刘秀玉,等.钢渣改性用于烟气脱硫研究进展[J].无机盐工业,2022,54(11):39-44.

|

|

DU Xiaoyan, LONG Hongming, LIU Xiuyu,et al.Research progress on flue gas desulfurization by modification of steel slag[J].Inorganic Chemicals Industry,2022,54(11):39-44.

|

| 3 |

华雯,吕瑞亮.湿法烟气脱硫技术应用现状及发展方向[J].无机盐工业,2022,54(12):10-18.

|

|

HUA Wen, Ruiliang LÜ.Application status and development direction of wet flue gas desulfurization technology[J].Inorganic Chemicals Industry,2022,54(12):10-18.

|

| 4 |

杨凤玲,翟敏,任磊,等.电石渣湿法脱硫中结晶产物的影响因素研究[J].无机盐工业,2023,55(2):92-98.

|

|

YANG Fengling, ZHAI Min, REN Lei,et al.Influencing factors of crystallization products in wet desulfurization of carbide slag[J].Inorganic Chemicals Industry,2023,55(2):92-98.

|

| 5 |

苏少龙,曲晓龙,孙彦民,等.高效环保脱硫剂的制备及性能研究[J].无机盐工业,2022,54(3):77-81.

|

|

SU Shaolong, QU Xiaolong, SUN Yanmin,et al.Study on preparation and performance of high efficient and environmental friendly desulfurizer[J].Inorganic Chemicals Industry,2022,54(3):77-81.

|

| 6 |

钟读乐,孙彦民,曲晓龙,等.新型高效催化脱硫剂的研究与应用[J].无机盐工业,2022,54(1):109-111.

|

|

ZHONG Dule, SUN Yanmin, QU Xiaolong,et al.Research and application of new high efficiency catalytic desulfurizer[J].Inorganic Chemicals Industry,2022,54(1):109-111.

|

| 7 |

KRAMMER G, REISSNER H K, STAUDINGER G.Cyclic activation of calcium hydroxide for enhanced desulfurization[J].Chemical Engineering and Processing:Process Intensification,2002, 41(5):463-471.

|

| 8 |

RENEDO M J, FERNÁNDEZ-FERRERAS J.Characterization and behavior of modified calcium-hydroxide-based sorbents in a dry desulfurization process[J].Energy & Fuels,2016,30(8):6350-6354.

|

| 9 |

乔波波,康安.氢氧化钙脱硫剂在烧结烟气湿法脱硫中的应用[J].包钢科技,2019,45(2):80-83.

|

|

QIAO Bobo, KANG An.Application for desulfurizer of calcium hydroxide in wet desulphurization for sintering flue gas[J].Science & Technology of Baotou Steel,2019,45(2):80-83.

|

| 10 |

陈文华,陈建华,赵俊峰.添加聚乙二醇对电厂烟气脱硫剂效率的影响分析[J].华东电力,2010,38(5):721-724.

|

|

CHEN Wenhua, CHEN Jianhua, ZHAO Junfeng.Analysis on effects of PEG on effience of calcium-based FGD sorbent[J].East China Electric Power,2010,38(5):721-724.

|

| 11 |

HASANOVA I, HASANOVA U, GASIMOV E,et al.PEG-assisted controlled precipitation of calcium hydroxide and calcium carbonate nanostructures for cement reinforcement[J].Materials Chemistry and Physics,2021,271.Doi:10.1016/j.matchemphys.2021.124865 .

|

| 12 |

陈建华,陈文华,赵俊峰.添加PEG对钙基烟气脱硫剂结构和性能的影响[J].煤炭转化,2010,33(2):85-87,91.

|

|

CHEN Jianhua, CHEN Wenhua, ZHAO Junfeng.Study on modification of structure and property of calcium-based fgd sorbent with peg[J].Coal Conversion,2010,33(2):85-87,91.

|

| 13 |

侯瑞琴,杜玉成,刘铮,等.纳米氢氧化钙颗粒制备、表征及NO x 捕获性能研究[J].非金属矿,2010,33(5):5-7,12.

|

|

HOU Ruiqin, DU Yucheng, LIU Zheng,et al.Study on preparation and characterization of nano-Ca(OH)2 and its adsorption performance to NO x [J].Non-Metallic Mines,2010,33(5):5-7,12.

|

| 14 |

李慧芝,李红,熊颖辉.异丙醇改性氢氧化钙的研究[J].无机盐工业,2008,40(9):32-34.

|

|

LI Huizhi, LI Hong, XIONG Yinghui.Study on modification of calcium hydroxide with isopropanol[J].Inorganic Chemicals Industry,2008,40(9):32-34.

|

| 15 |

王籽明,彭问安,孙青,等.纳米氢氧化钙制备方法的改良及作为根管治疗糊剂的生物安全性初探[J].口腔医学研究,2018,34(4):428-431.

|

|

WANG Ziming, PENG Wenan, SUN Qing,et al.Modification of preparation method of nanometer calcium hydroxide and preliminary assessment of biological safety for root canal therapy[J].Journal of Oral Science Research,2018,34(4):428-431.

|

| 16 |

许昌日,张涌新,邬成贤,等.高效脱硫复合添加剂配方筛选及增效试验研究[J].能源工程,2014(4):53-58.

|

|

XU Changri, ZHANG Yongxin, WU Chengxian,et al.Research of composite additive on high efficient desulfurization[J].Energy Engineering,2014(4):53-58.

|

| 17 |

TENG Yang, LI Lijiao, XU Gang,et al.Promoting effect of inorganic alkali on carbon dioxide adsorption in amine-modified MCM-41[J].Energies,2016,9(9).Doi:10.3390/en9090667 .

|

| 18 |

颜秉浩,乔朋,高磊.烧结用石灰粉中氢氧化钙鉴别方法探索[J].新疆钢铁,2020(3):22-24.

|

|

YAN Binghao, QIAO Peng, GAO Lei.Identification of calcium hydroxide in lime powder for sintering[J].Xinjiang Iron and Steel, 2020(3):22-24.

|

| 19 |

LIU Faqian, LIU Xin, SUN Lishui,et al.MXene-supported stable adsorbents for superior CO2 capture[J].Journal of Materials Che- mistry A,2021,9(21):12763-12771.

|

| 20 |

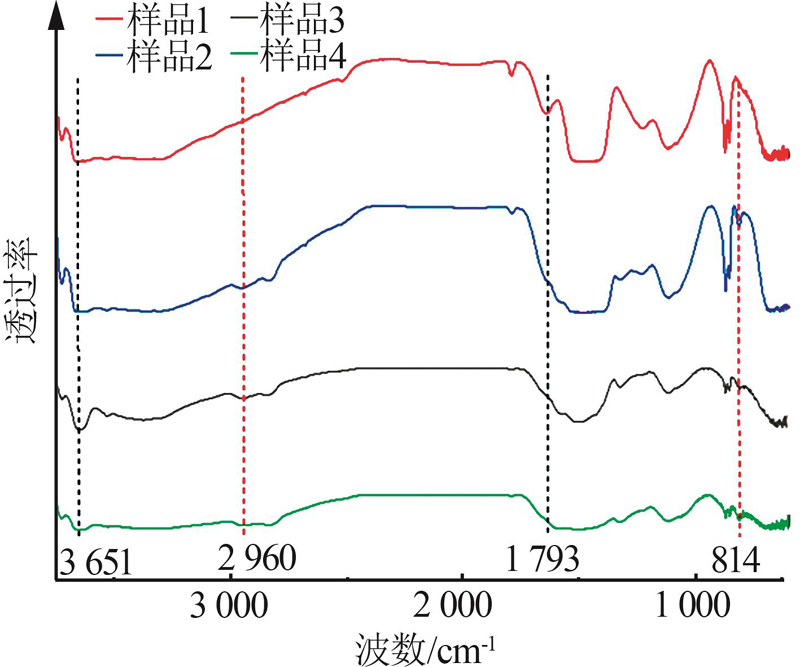

张彬,肖霄,韩芸娇,等.碳酸钙三级红外光谱研究[J].无机盐工业,2021,53(1):97-101.

|

|

ZHANG Bin, XIAO Xiao, HAN Yunjiao,et al.Study on third-step infrared spectroscopy of calcium carbonate[J].Inorganic Che-Industry micals,2021,53(1):97-101.

|

), LI Shizhu1, ZHENG Dongchen2, ZENG Tinghua3, WU Zhichao1, YU Chi1, LIU Faqian2(

), LI Shizhu1, ZHENG Dongchen2, ZENG Tinghua3, WU Zhichao1, YU Chi1, LIU Faqian2( )

)