| [1] |

GONG J, LUQUE R. Catalysis for production of renewable energy[J]. Chemical Society Reviews, 2014, 43(22):7466-7468.

doi: 10.1039/C4CS90084G

|

| [2] |

吴玉琪, 靳治良, 李越湘, 等. 半导体光催化剂制氢研究新进展[J]. 分子催化, 2010, 2(4):171-194.

|

| [3] |

SANG Y, LIU H, UMAR A. Photocatalysis from UV/Vis to near-infrared light:Towards full solar-light spectrum activity[J]. ChemCatChem, 2015, 7(4):559-573.

doi: 10.1002/cctc.201402812

|

| [4] |

XIAO M, WANG S, THAWEESAK S, et al. Tantalum(oxy)nitride: Narrow bandgap photocatalysts for solar hydrogen generation[J]. Engineering, 2017, 3(3):365-378.

doi: 10.1016/J.ENG.2017.03.019

|

| [5] |

刘美英, 由万胜, 雷志斌, 等. 可见光作用下LaTaON2催化剂光催化分解水制氢[J]. 催化学报, 2006, 7(2):556-558.

|

| [6] |

MORIYA Y, TAKATA T, DOMEN K, et al. Recent progress in the development of (oxy)nitride photocatalysts for water splitting under visible-light irradiation[J]. Coordination Chemistry Reviews, 2013, 257:1957-1969.

doi: 10.1016/j.ccr.2013.01.021

|

| [7] |

SEO J, HISATOMI T, NAKABAYASHI M, et al. Efficient solar-dri-ven water oxidation over perovskite-type BaNbO2N photoanodes absorbing visible light up to 740 nm[J]. Advanced Energy Materials, 2018, 8(24).Doi: 10.1002/aenm.201800094.

doi: 10.1002/aenm.201800094

|

| [8] |

SIRITANARATKUL B, MAEDA K, HISATOMI T, et al. Synjournal and photocatalytic activity of perovskite niobium oxynitrides with wide visible-light absorption bands[J]. ChemSusChem, 2011, 4(1):74-78.

doi: 10.1002/cssc.v4.1

|

| [9] |

HISATOMI T, KATAYAMA C, MORIYA Y, et al. Photocatalytic oxy-gen evolution using BaNbO2N modified with cobalt oxide under pho-toexcitation up to 740 nm[J]. Energy & Environmental Science, 2013, 6(12):3595-3599.

|

| [10] |

JADHAV S, HASEGAWA S, HISATOMI T, et al. Efficient photo-catalytic oxygen evolution using BaTaO2N obtained from nitrida-tion of perovskite-type oxide[J]. Journal of Materials Chemistry A, 2020, 8(3):1127-1130.

doi: 10.1039/C9TA10684G

|

| [11] |

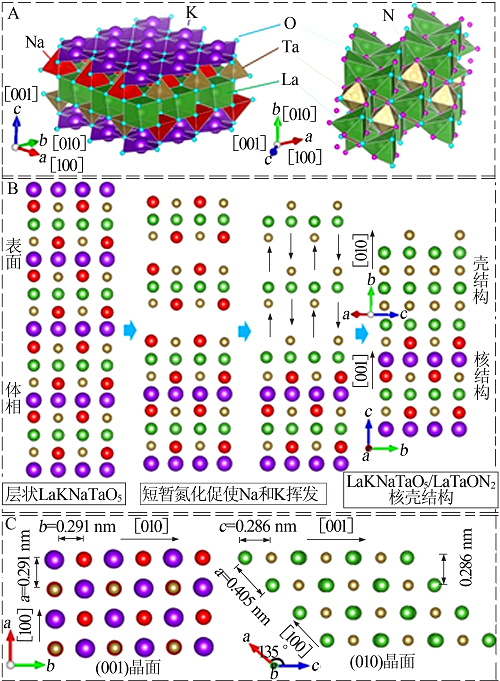

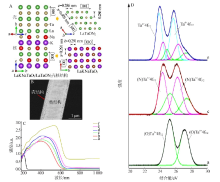

WANG X, HISATOMI T, WANG Z, et al. Core-shell-structured LaTaON2 transformed from LaKNaTaO5 plates for enhanced photo-catalytic H2 evolution[J]. Angewandte Chemie International Edi-tion, 2019, 58(31):10666-10670.

|

| [12] |

ZHANG F, YAMAKATA A, MAEDA K, et al. Cobalt-modified po-rous single-crystalline LaTiO2N for highly efficient water oxida-tion under visible light[J]. Journal of the American Chemical So-ciety, 2012, 134(20):8348-8351.

|

| [13] |

WANG Z, INOUE Y, HISATOMI T, et al. Overall water splitting by Ta3N5 nanorod single crystals grown on the edges of KTaO3 parti-cles[J]. Nature Catalysis, 2018, 1(10):756-763.

doi: 10.1038/s41929-018-0134-1

|

| [14] |

FU J, SKRABALAK S. Enhanced photoactivity from single-crysta-lline SrTaO2N nanoplates synthesized by topotactic nitridation[J]. Angewandte Chemie International Edition, 2017, 56(45):14169-14173.

doi: 10.1002/anie.v56.45

|

| [15] |

TAKATA T, JIANG J, SAKATA Y, et al. Photocatalytic water spli-tting with a quantum efficiency of almost unity[J]. Nature, 2021, 581(7809):411-414.

doi: 10.1038/s41586-020-2278-9

|

| [16] |

OSHIMA T, ICHIBHA T, QIN K, et al. Undoped layered perovskite oxynitride Li2LaTa2O6N for photocatalytic CO2 reduction with visible light[J]. Angewandte Chemie International Edition, 2018, 57(27):8154-8158.

doi: 10.1002/anie.v57.27

|

| [17] |

JIANG H, CUAN Q, WEN C, et al. Anatase TiO2 crystals with expo-sed high-index facets[J]. Angewandte Chemie International Edi-tion, 2011, 50(16):3764-3768.

|

| [18] |

WANG H, GAO J, GUO T, et al. Facile synjournal of AgBr nanoplat-es with exposed{111} facets and enhanced photocatalytic proper-ties[J]. Chemical Communication, 2012, 48(2):275-277.

doi: 10.1039/C1CC16423F

|

| [19] |

KATO H, KOBAYASHI M, HARA M, et al. Fabrication of SrTiO3 exposing characteristic facets using molten salt flux and improve-ment of photocatalytic activity for water splitting[J]. Catalysis Sci-ence & Technology, 2013, 3(7):1733-1738.

|

| [20] |

XU H, REUNCHAN P, OUYANG S, et al. Anatase TiO2 single crys-tals exposed with high-reactive{111} facets toward efficient H2 ev-olution[J]. Chemistry of Materials, 2013, 25(3):405-411.

doi: 10.1021/cm303502b

|

| [21] |

ZHU Y, LV C, YIN Z, et al. [001]-oriented hittorf′s phosphorus nanorods/polymeric carbon nitride heterostructure for boosting wide-spectrum-responsive photocatalytic hydrogen evolution from pure water[J]. Angewandte Chemie International Edition, 2020, 59(2):868-873.

doi: 10.1002/anie.v59.2

|

| [22] |

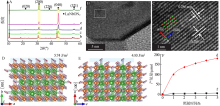

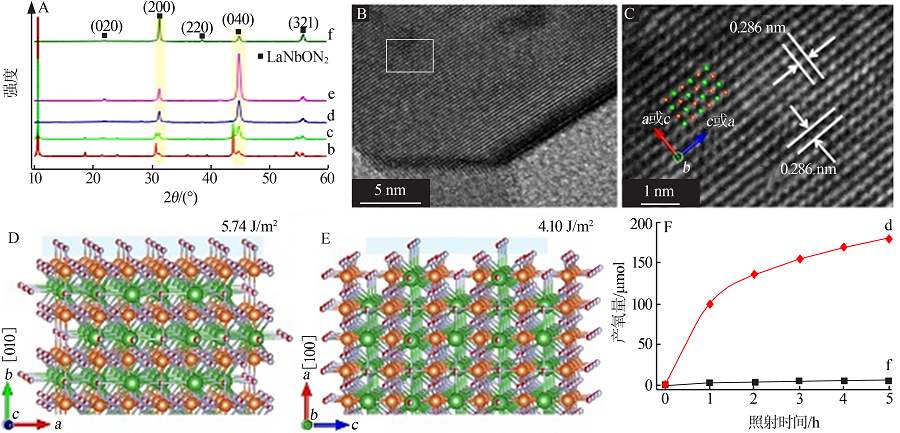

WANG X, HISATOMI T, LIANG J, et al. Facet engineering of LaNbON2 transformed from LaKNaNbO5 for enhanced photocataly-tic O2 evolution[J]. Journal of Materials Chemistry A, 2020, 8(23):11743-11751.

doi: 10.1039/D0TA01489C

|