Inorganic Chemicals Industry ›› 2022, Vol. 54 ›› Issue (6): 109-114.doi: 10.19964/j.issn.1006-4990.2021-0530

• Environment·Health·Safety • Previous Articles Next Articles

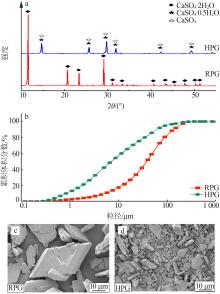

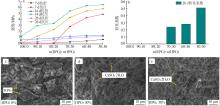

Study on preparation of cementitious materials from raw phosphogypsum cured by hemihydrate phosphogypsum and their properties

FU Rusong( ),LU Yuexian,AN Hongfang,KONG Dewen(

),LU Yuexian,AN Hongfang,KONG Dewen( ),FU Rubin

),FU Rubin

- College of Civil Engineering,Guizhou University,Guiyang,550025 China

-

Received:2021-10-11Online:2022-06-10Published:2022-06-22 -

Contact:KONG Dewen E-mail:1799244812@qq.com;kongdewen0608@126.com

CLC Number:

Cite this article

FU Rusong,LU Yuexian,AN Hongfang,KONG Dewen,FU Rubin. Study on preparation of cementitious materials from raw phosphogypsum cured by hemihydrate phosphogypsum and their properties[J]. Inorganic Chemicals Industry, 2022, 54(6): 109-114.

share this article

| 1 | 尹明干,汪晖,石飞停.改性磷石膏的强度与孔结构的研究[J].材料导报,2018,32(S2):526-529. |

| YIN Minggan, WANG Hui, SHI Feiting.Mechanical strength and pore structure analysis of modified phosphogypsum[J].Materials Review,2018,32(S2):526-529. | |

| 2 | 饶轶晟,王凤霞.磷石膏资源化利用途径及展望[J].化工矿物与加工,2020,49(8):30-33. |

| RAO Yisheng, WANG Fengxia.Utilization of phosphogypsum as resource and its prospect[J].Industrial Minerals & Processing,2020,49(8):30-33. | |

| 3 | 石鑫,杨绍利,马兰.“三石膏”综合利用现状及其新工艺[J].现代化工,2020,40(9):8-13,19. |

| SHI Xin, YANG Shaoli, MA Lan.Present situation of comprehensive utilization of “three⁃gypsum” and new technologies[J].Modern Chemical Industry,2020,40(9):8-13,19. | |

| 4 | 袁书成,刘香玲,梁危,等.磷石膏填充墙研究现状与应用进展[J].无机盐工业,2021,53(4):8-13. |

| YUAN Shucheng, LIU Xiangling, LIANG Wei,et al.Research status and application progress of phosphogypsum infilled walls[J].Inorganic Chemicals Industry,2021,53(4):8-13. | |

| 5 | 孙潇潇.煅烧磷石膏—矿渣—碱性激发剂胶凝材料的性能研究[D].郑州:郑州大学,2020. |

| SUN Xiaoxiao.Study on the properties of calcined phosphogypsum⁃ | |

| slagalkaline activator cementitious material[D].Zhengzhou:Zheng | |

| zhou University,2020. | |

| 6 | 赵风文,胡建华,曾平平,等.基于正交试验的碱基-磷石膏胶结充填体配比优化[J].中国有色金属学报,2021,31(4):1096-1105. |

| ZHAO Fengwen, HU Jianhua, ZENG Pingping,et al.Optimization research of base⁃phosphogypsum cemented backfill ratio based on orthogonal test[J].The Chinese Journal of Nonferrous Metals,2021, | |

| 31(4):1096-1105. | |

| 7 | 魏兴,郑光亚,何宣志,等.磷石膏复合胶凝材料的制备及胶结过程研究[J].现代化工,2021,41(9):101-106. |

| WEI Xing, ZHENG Guangya, HE Xuanzhi,et al.Preparation and cementation process of phosphogypsum composite cementing material[J].Modern Chemical Industry,2021,41(9):101-106. | |

| 8 | 李宏业,杨晓炳,温震江,等.磷石膏—矿渣复合胶凝材料配比优化试验[J].金属矿山,2021(3):28-33. |

| LI Hongye, YANG Xiaobing, WEN Zhenjiang,et al.Optimization test of the proportion of phosphogypsum⁃slag composite cementitious material[J].Metal Mine,2021(3):28-33. | |

| 9 | 吴照洋,张永兴,张利珍,等.磷石膏一步法制备β型建筑石膏粉试验研究[J].化工矿物与加工,2021,50(6):36-40. |

| WU Zhaoyang, ZHANG Yongxing, ZHANG Lizhen,et al.Experimental study on preparation of β-building gypsum powder with phosphogypsum by one⁃step method[J].Industrial Minerals & Processing,2021,50(6):36-40. | |

| 10 | 郑绍聪,余强,宁平,等.磷石膏制备β半水石膏粉的研究[J].现代化工,2015,35(5):60-63,65. |

| ZHENG Shaocong, YU Qiang, NING Ping,et al.Preparation of β-hemihydrate gypsum with phosphogypsum[J].Modern Chemical Industry,2015,35(5):60-63,65. | |

| 11 |

CHEN Xuemei, GAO Jianming, ZHAO Yasong.Investigation on the

doi: 10.1016/j.conbuildmat.2019.116864 |

|

hydration of hemihydrate phosphogypsum after post treatment[J].Construction and Building Materials,2019,229.Doi:10.1016/j.conbuildmat.2019.116864 .

doi: 10.1016/j.conbuildmat.2019.116864 |

|

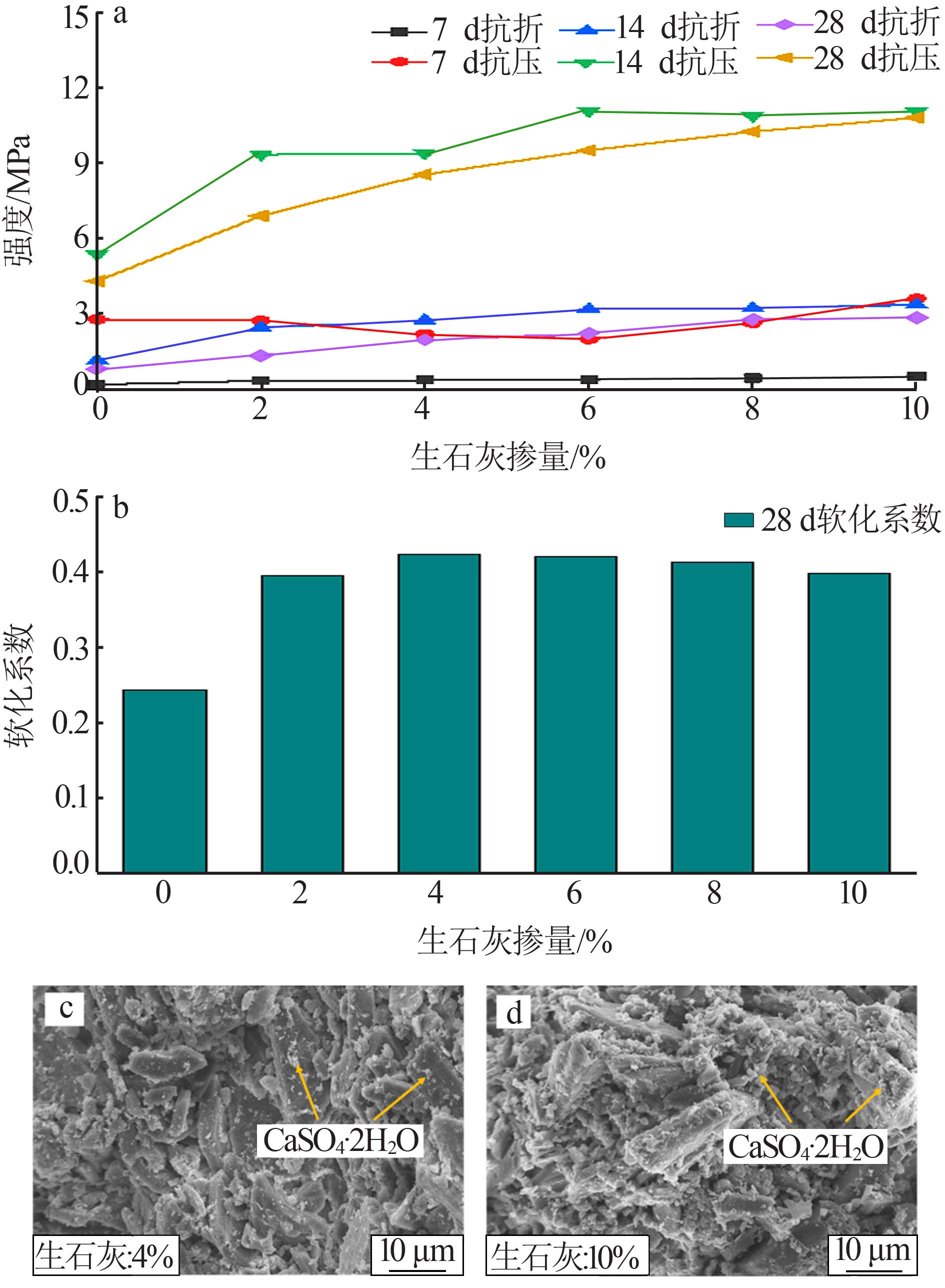

| 12 | 姜关照,吴爱祥,王贻明,等.生石灰对半水磷石膏充填胶凝材料性能影响[J].硅酸盐学报,2020,48(1):86-93. |

| JIANG Guanzhao, WU Aixiang, WANG Yiming,et al.Effect of lime on properties of filling cementitious material prepared by hemihydrate phosphogypsum[J].Journal of the Chinese Ceramic Society,2020,48(1):86-93. | |

| 13 | 兰文涛,吴爱祥,王贻明,等.半水磷石膏充填强度影响因素试验[J].哈尔滨工业大学学报,2019,51(8):128-135. |

| LAN Wentao, WU Aixiang, WANG Yiming,et al.Experimental study on influencing factors of the filling strength of hemihydrate phosphogypsum[J].Journal of Harbin Institute of Technology,2019,51(8):128-135. | |

| 14 | 齐兆军,刘树龙,孙业庚,等.新型充填胶凝材料影响因素分析及配比优化[J].矿业研究与开发,2021,41(2):114-118. |

| QI Zhaojun, LIU Shulong, SUN Yegeng,et al.Analysis on influencing factors and proportion optimization of new filling cementing materials[J].Mining Research and Development,2021,41(2):114-118. | |

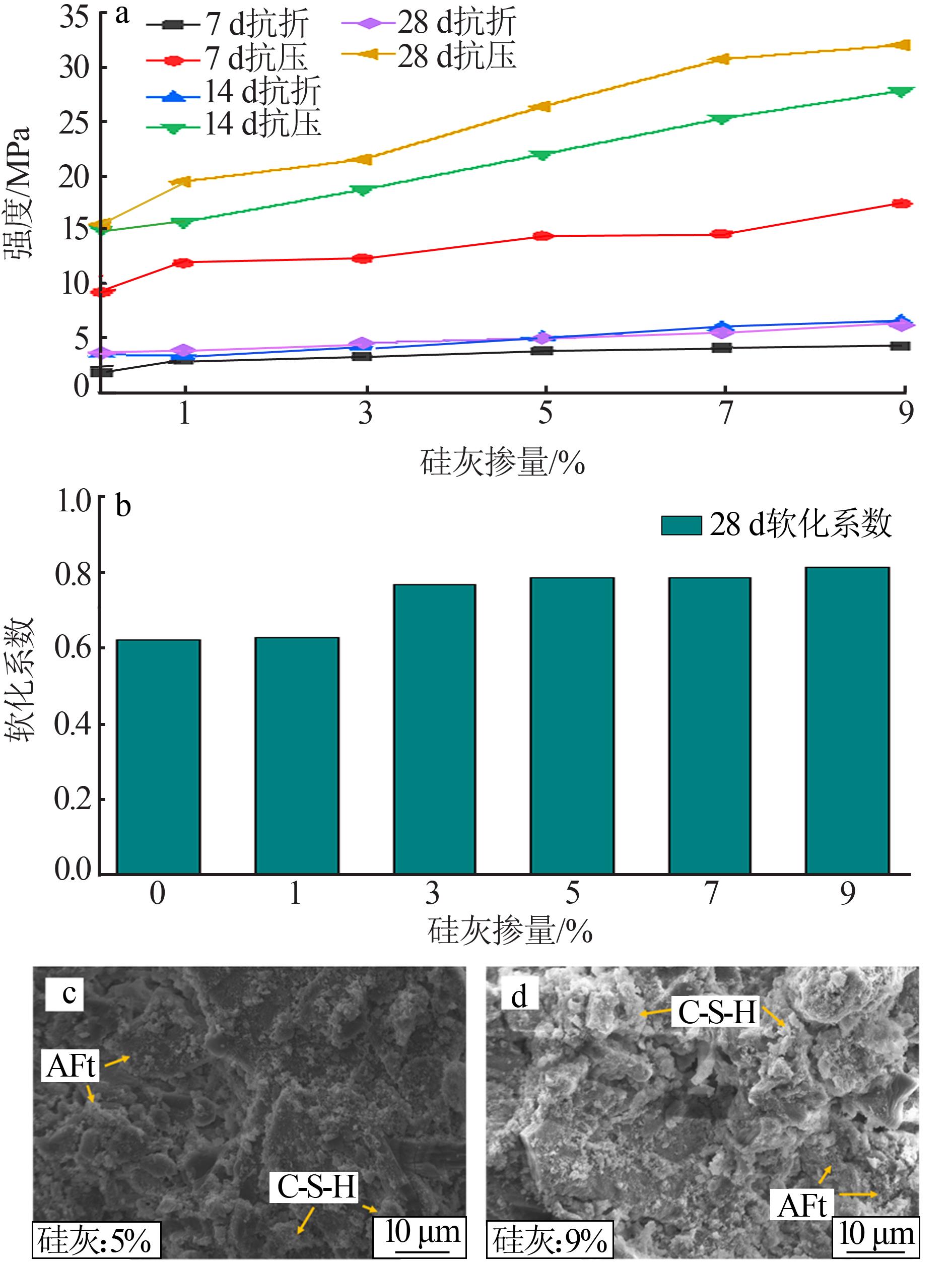

| 15 | 杨艳娟,王今华,白召军,等.双掺粉煤灰和硅灰透水混凝土的试验研究[J].新型建筑材料,2021,48(2):78-80. |

| YANG Yanjuan, WANG Jinhua, BAI Zhaojun,et al.Experimental study on permeable concrete mixed with fly ash and silica fume[J].New Building Materials,2021,48(2):78-80. | |

| 16 | 王红珊,王海龙,孙松,等.硅粉对轻骨料混凝土力学性能及孔隙结构的影响[J].中国科技论文,2019,14(4):458-463. |

| WANG Hongshan, WANG Hailong, SUN Song,et al.Effect of silicon powder on mechanical properties and pore structure of lightweight aggregate concrete[J].China Sciencepaper,2019,14(4):458-463. | |

| 17 | 张雄,张恒,张晓乐,等.硅灰调控混凝土力学性能的关键界面参数研究[J].建筑材料学报,2019,22(4):626-631. |

| ZHANG Xiong, ZHANG Heng, ZHANG Xiaole,et al.Key interface parameters for the control of silica fume on mechanical properties of concrete[J].Journal of Building Materials,2019,22(4):626-631. |

| [1] | WANG Peixiong, GONG Xiaomei, DING Jiaqi, CAO Hong. Effect of crystal modifier on preparation of α-hemihydrates gypsum from industrial gypsum [J]. Inorganic Chemicals Industry, 2024, 56(4): 112-117. |

| [2] | YU Zhou, HE Zhaoyi, TANG Liang, HE Sheng, XIAO Haixin, XIAO Yixun. Study on preparation and microscopic properties of typical sulfate solid waste composite cementitious materials [J]. Inorganic Chemicals Industry, 2024, 56(4): 90-97. |

| [3] | CHEN Feng, FENG Kang, LI Ming, SHEN Haojie, TIAN Chengtao, TANG Yuan, LI Zhili, HE Dongsheng. Application of organically modified calcium sulfate whiskers in asphalt modification [J]. Inorganic Chemicals Industry, 2024, 56(3): 125-130. |

| [4] | WANG Ruting, ZHAO Xiaorong, HUANG Xuquan, WANG Haojie, XUE Fei, CAI Jiawei. Research on preparation and early performance of mixed phase phosphogypsum-based cementing materials [J]. Inorganic Chemicals Industry, 2024, 56(3): 98-104. |

| [5] | ZHANG Guidong, YANG Xuejiao, GUO Xudong, YANG Lin. Study on hydration properties of type Ⅱ anhydrite prepared by calcination and atmospheric acidification [J]. Inorganic Chemicals Industry, 2024, 56(2): 104-110. |

| [6] | WANG Yanyu, GU Shouyu, HOU Cuihong, JING Hongquan, GUAN Hongling, ZHANG Hui. Sulfur escape and slag physical phase analysis by carbon thermal reduction melting based on phosphogypsum ingredients [J]. Inorganic Chemicals Industry, 2024, 56(2): 86-94. |

| [7] | DENG Hua, HOU Shuomin, LI Zhongjun, XU Gang, CHI Ru′an, XI Benjun. Current situation and prospect of comprehensive utilization of phosphogypsum [J]. Inorganic Chemicals Industry, 2024, 56(1): 1-8. |

| [8] | XIA Guiying, YANG Liuchun, YUAN Zhiye. Study on direct leaching of rare earth elements from phosphogypsum with sulfuric acid [J]. Inorganic Chemicals Industry, 2024, 56(1): 107-113. |

| [9] | LI Qiang, YOU Xiaomin, SHE Xuefeng, JIANG Zeyi, XUE Qingguo, WANG Jingsong. Effect of calcination temperature and carbon structure on compressive strength of CaO-containing carbon pellets [J]. Inorganic Chemicals Industry, 2023, 55(9): 43-49. |

| [10] | CUI Gengyin, XIE Lang, LU Yuexian, KONG Dewen, WANG Lingling. Optimization of mechanical properties of basalt fiber reinforced phosphogypsum-based composites based on RSM [J]. Inorganic Chemicals Industry, 2023, 55(8): 116-123. |

| [11] | LI Heng, ZHANG Hui, ZI Xuemin. Analysis on calcination process progress of phosphogypsum [J]. Inorganic Chemicals Industry, 2023, 55(6): 27-35. |

| [12] | ZHANG Lei, LI Meng, XIANG Wenguo, HU Jun, CHEN Shiyi, DUAN Lunbo. Feasibility analysis of calcination and decomposition process of phosphogypsum in circulating fluidized bed [J]. Inorganic Chemicals Industry, 2023, 55(6): 85-91. |

| [13] | XU Li, FANG Keneng, BI Yongxiang, YANG Min, CHEN Qianlin. Preparation of modified granular-like CaSO4 and its application in polyvinyl chloride [J]. Inorganic Chemicals Industry, 2023, 55(3): 104-112. |

| [14] | GUO Shuang, XING Dongxian, GUO Xiao, JI Xiaojie, TANG Jianwei, HUA Quanxian, WANG Baoming, LIU Yong. Study on preparation and modification of phosphogypsum-based architectural gypsum [J]. Inorganic Chemicals Industry, 2023, 55(12): 102-110. |

| [15] | LIU Chao, FAN Chuigang, LIU Runguo, YU Dongxue, LI Songgeng. Preparation of α-hemihydrate gypsum from phosphogypsum by flotation and atmospheric trans-crystallization in solution [J]. Inorganic Chemicals Industry, 2023, 55(11): 107-114. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||