| 1 |

宫海燕,李彩虹,王佩佩,等.硫酸钙晶须的制备现状[J].无机盐工业,2010,42(10):1-4.

|

|

GONG Haiyan, LI Caihong, WANG Peipei,et al.Current status of preparation of calcium sulphate whiskers[J].Inorganic Chemicals Industry,2010,42(10):1-4.

|

| 2 |

郑绍聪,余强,谢刚,等.用盐酸溶解工业磷石膏重结晶法制备硫酸钙晶须[J].湿法冶金,2016,35(6):488-491.

|

|

ZHENG Shaocong, YU Qiang, XIE Gang,et al.Preparating of calcium sulphate whisker using phosphogypsum by recrystallization[J].Hydrometallurgy of China,2016,35(6):488-491.

|

| 3 |

杨林,周杰,李贺军,等.晶形助长剂对磷石膏制硫酸钙晶须性能的影响[J].无机盐工业,2012,44(10):41-43.

|

|

YANG Lin, ZHOU Jie, LI Hejun,et al.Influence of crystal growing agent on properties of calcium sulfate whisker with phosphogypsum[J].Inorganic Chemicals Industry,2012,44(10):41-43.

|

| 4 |

付凌杰,崔益顺,李国勇.硫酸钙晶须制备方法及应用进展[J].四川理工学院学报:自然科学版,2013,26(5):7-10.

|

|

FU Lingjie, CUI Yishun, LI Guoyong.Preparation for calcium sulfate whisker and its application process[J].Journal of Sichuan University of Science & Engineering:Natural Science Edition,2013,26(5):7-10.

|

| 5 |

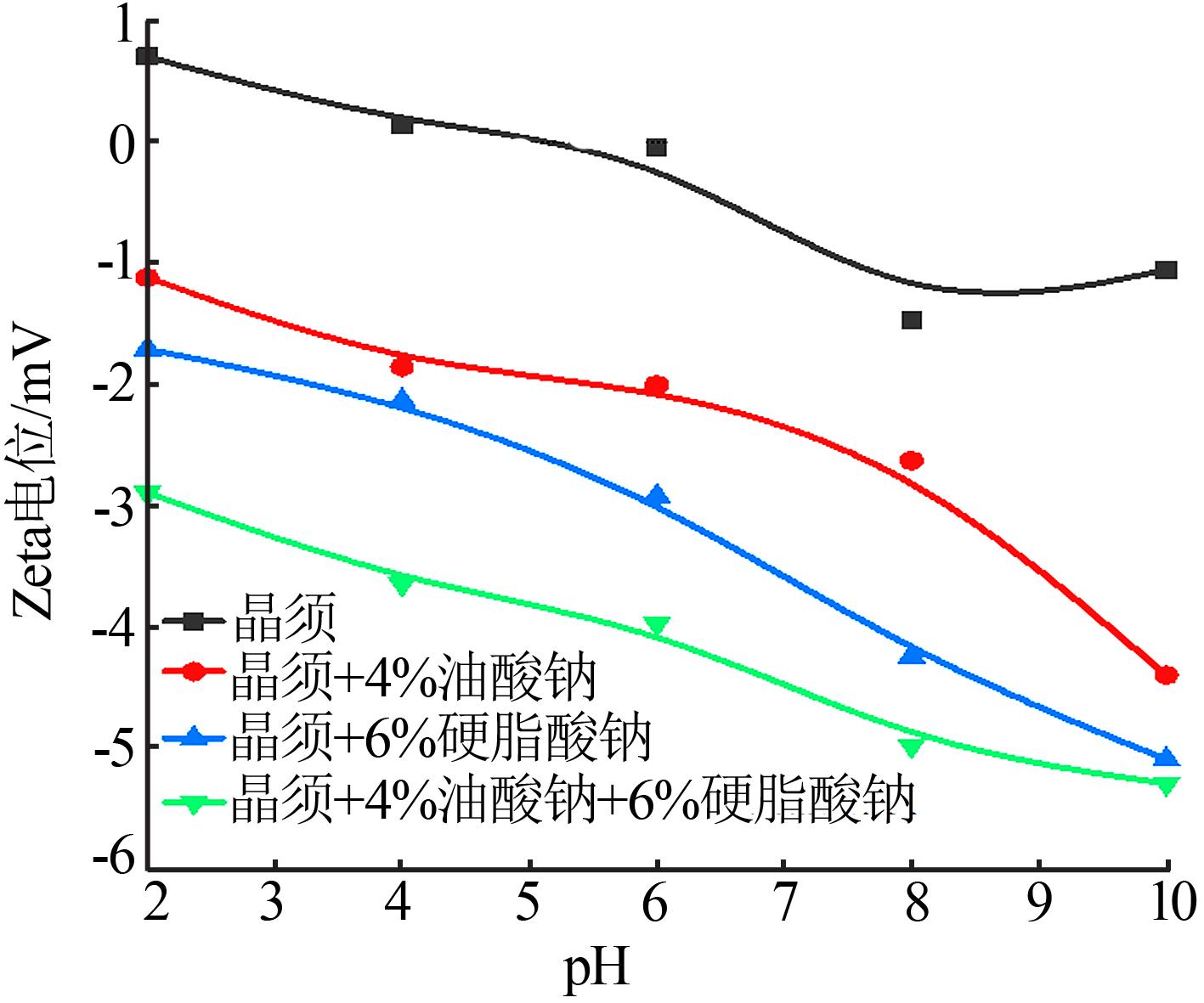

郝海青,袁致涛,李丽匣,等.油酸钠控制硫酸钙晶须晶面生长的机理研究[J].无机材料学报,2016,31(11):1184-1190.

|

|

HAO Haiqing, YUAN Zhitao, LI Lixia,et al.Mechanism of faces growth in preparing calcium sulphate whiskers using sodium olea⁃

|

|

te[J].Journal of Inorganic Materials,2016,31(11):1184-1190.

|

| 6 |

谢晴,蒋美雪,彭同江,等.磷石膏常压酸化法制备无水硫酸钙晶须的实验研究[J].人工晶体学报,2019,48(6):1060-1066,1071.

|

|

XIE Qing, JIANG Meixue, PENG Tongjiang,et al.Experimental study on preparation of anhydrous calcium sulfate whisker by phosphogypsum at atmospheric acidification method[J].Journal of Synthetic Crystals,2019,48(6):1060-1066,1071.

|

| 7 |

马园园,王铭佳,刘在彤,等.氯化钙制备半水硫酸钙晶须的工艺研究[J].无机盐工业,2018,50(8):52-56.

|

|

MA Yuanyuan, WANG Mingjia, LIU Zaitong,et al.Study on preparation of hemihydrate calcium sulfate whiskers by calcium chlori⁃

|

|

de[J].Inorganic Chemicals Industry,2018,50(8):52-56.

|

| 8 |

马小玲,谭宏斌,杨飞华.常压酸水体系制备无水硫酸钙晶须及形貌调控[J].非金属矿,2021,44(1):81-83.

|

|

MA Xiaoling, TAN Hongbin, YANG Feihua.Preparation and morphology control of anhydrous calcium sulfate whiskers in acid water system under autoclave⁃free[J].Non-Metallic Mines,2021,

|

|

44(1):81-83.

|

| 9 |

耿世伟,曹钰,罗康碧,等.硫酸钙晶须的表面改性研究现状[J].化工新型材料,2019,47(10):224-227.

|

|

GENG Shiwei, CAO Yu, LUO Kangbi,et al.Research status on surface modification of calcium sulfate whisker[J].New Chemical Materials,2019,47(10):224-227.

|

| 10 |

史培阳,邓志银,袁义义,等.利用脱硫石膏水热合成硫酸钙晶须[J].东北大学学报:自然科学版,2010,31(1):76-79.

|

|

SHI Peiyang, DENG Zhiyin, YUAN Yiyi,et al.Preparation of calcium sulfate whiskers from desulphurized gypsum by hydrothermal synthesis[J].Journal of Northeastern University:Natural Science,2010,31(1):76-79.

|

| 11 |

侯炜,王鸿康,王少青,等.水热法制备硫酸钙晶须[J].内蒙古石油化工,2017,43(3):16-18.

|

|

HOU Wei, WANG Hongkang, WANG Shaoqing,et al.Preparation of calcium sulfate whiskers by hydrothermal method[J].Inner Mongolia Petrochemical Industry,2017,43(3):16-18.

|

| 12 |

徐伟.稀土石膏常压酸化法制备硫酸钙晶须及其改性的研究[D].包头:内蒙古科技大学,2020.

|

|

XU Wei.Study on preparation of calcium sulfate whiskers by rare⁃earth gypsum under normal pressure acidification and related modification[D].Baotou:Inner Mongolia University of Science & Technology,2020.

|

| 13 |

王艾文.磷石膏常压无氯盐溶液法制备硫酸钙晶须[D].绵阳:西南科技大学,2021.

|

|

WANG Aiwen.Preparation of calcium sulfate whiskers from phosphogypsum by chlorine⁃free salt solution method at atmospheric pressure[D].Mianyang:Southwest University of Science and Te⁃

|

|

chnology,2021.

|

| 14 |

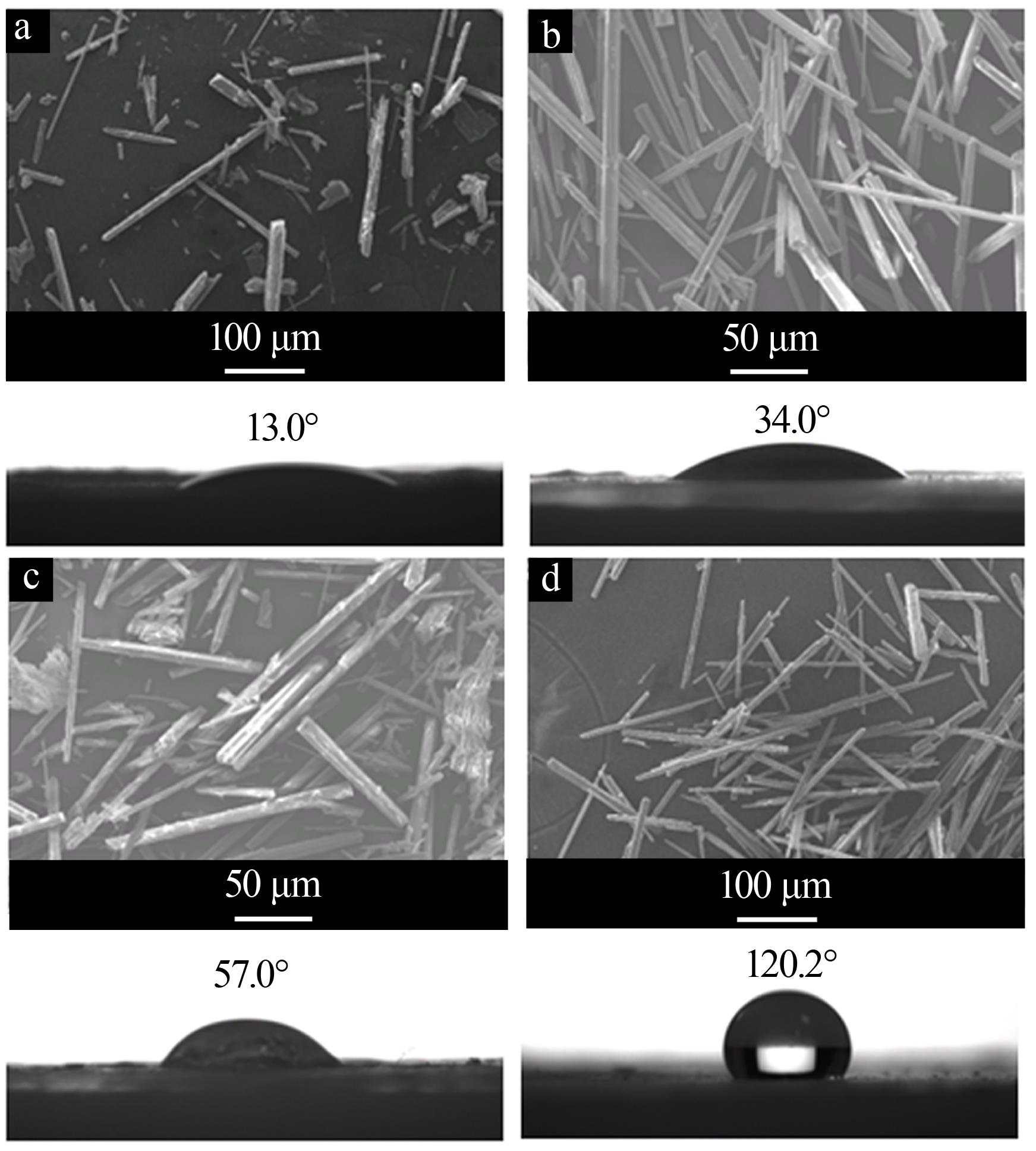

黄旭,黄健,牛韵雅,等.磷石膏制备的耐热半水硫酸钙晶须表面疏水改性研究[J].硅酸盐通报,2019,38(7):2021-2027.

|

|

HUANG Xu, HUANG Jian, NIU Yunya,et al.Research on surface hydrophobic modification of heat⁃resistant calcium sulfate he⁃

|

|

hemihydrate whisker prepared from phosphogypsum[J].Bulletin of the Chinese Ceramic Society,2019,38(7):2021-2027.

|

),LI Zhili1,2(

),LI Zhili1,2( ),ZHANG Zeqiang1,HE Dongsheng1,TANG Yuan1,CHEN Fei1

),ZHANG Zeqiang1,HE Dongsheng1,TANG Yuan1,CHEN Fei1