| 1 |

刘润静,徐恺,张腾腾.我国轻烧粉、重烧粉及电熔镁砂生产现状分析[C]∥2014年全国镁化合物行业年会暨技术设备交流会专辑.石家庄:中国无机盐工业协会镁化合物分会,2014:62-

|

| 69 |

LIU Runjing, XU Kai, ZHANG Tengteng.Analysis of production status of light burned powder、heavy burned powder and fused magnesia in China[C]∥2014 National Magnesium Compound Industry Annual Meeting and Technical Equipment Exchange Conference album.Shijiazhuang:China Inorganic Salt Industry Association Magnesium Compaunds Brarch,2014:62-69.

|

| 2 |

侯庆冬,罗旭东,谢志鹏,等.镁橄榄石前驱体溶胶结合电熔镁砂基耐火材料基质的烧结性能[J].耐火材料,2018,52(6):426-429.

|

|

HOU Qingdong, LUO Xudong, XIE Zhipeng,et al.Sintering property of forsterite precursor Sol bonded fused magnesia refractory matrix[J].Refractories,2018,52(6):426-429.

|

| 3 |

POURRAHIMI A M, PALLON L K H, LIU Dongming,et al.Poly⁃

|

|

ethylene nanocomposites for the next generation of ultralow⁃trans⁃

|

|

transmission-loss HVDC cables:Insulation containing moisture⁃

|

|

resistant MgO nanoparticles[J].ACS Applied Materials & Interfa⁃

|

|

ces,2016,8(23):14824-14835.

|

| 4 |

徐娜,李志坚,吴锋,等.复合添加剂对镁碳砖高温性能的影响[J].无机盐工业,2015,47(8):45-48,55.

|

|

XU Na, LI Zhijian, WU Feng,et al.Effect of combined additives on high⁃temperature properties of MgO-C brick[J].Inorganic Chemicals Industry,2015,47(8):45-48,55.

|

| 5 |

刘景林.冶金设备用耐火材料[J].耐火与石灰,2010,35(2):65-66.

|

|

LIU Jinglin.Refractory materials used in metallurgical equipme⁃

|

|

nt[J].Refractories & Lime,2010,35(2):65-66.

|

| 6 |

陈英春,周佳芬,路贵民,等.高纯镁砂及氧化镁陶瓷研究进展[J].化工进展,2019,38(1):505-515.

|

|

CHEN Yingchun, ZHOU Jiafen, LU Guimin,et al.A review on the production technologies of high⁃purity magnesia and magnesium oxide ceramics[J].Chemical Industry and Engineering Progress,2019,38(1):505-515.

|

| 7 |

兰伟.以烧结镁砂为基质的人工湿地强化除磷效果及其作用机制[D].济南:山东大学,2018.

|

|

LAN Wei.Phosphorus removal enhancement of magnesia modified constructed wetland microcosm and its mechanism study[D].Jinan:Shandong University,2018.

|

| 8 |

全跃.试论采用煤气发生炉治理轻烧镁砂窑烟尘[J].辽宁经济,2001(5):6-7,48.

|

|

QUAN Yue.Discussion on using gas producer to treat dust of light burned magnesia kiln[J].Liaoning Economy,2001(5):6-7,48.

|

| 9 |

李军,宋伟.电熔镁产业发展研究[J].冶金能源,2010,29(4):8-10.

|

|

LI Jun, SONG Wei.Research on development of fused magnesia industry[J].Energy for Metallurgical Industry,2010,29(4):8-10.

|

| 10 |

张芳.电熔镁砂市场分析及发展优势[J].包钢科技,2003,29(1):87-88,78.

|

|

ZHANG Fang.Development of electric melting magnesia mar⁃

|

|

ket[J].Science & Technology of Baotou Steel(Group) Corporation,2003,29(1):87-88,78.

|

| 11 |

徐恺,赵华,杨翠杰,等.高活性氧化镁潮解及其活性递变规律研究[J].无机盐工业,2016,48(10):44-46.

|

|

XU Kai, ZHAO Hua, YANG Cuijie,et al.Study on high activity magnesium oxide deliquescence and its active change law[J].Inorganic Chemicals Industry,2016,48(10):44-46.

|

| 12 |

AMARAL L F, OLIVEIRA I R, BONADIA P,et al.Chelants to inhibit magnesia(MgO) hydration[J].Ceramics International, 2011,37(5):1537-1542.

|

| 13 |

于秋月.MgO-CaO耐火材料抗水化性能研究进展[J].有色矿冶,2018,34(2):39-42.

|

|

YU Qiuyue.Progress in research on hydration resistance of MgO-CaO refractories[J].Non-Ferrous Mining and Metallurgy,2018,34(2):39-42.

|

| 14 |

宋柯成,宿金栋,陈俊红,等.镁砂水化性能研究[J].四川冶金,2013,35(2):58-61.

|

|

SONG Kecheng, SU Jindong, CHEN Junhong,et al.A performance study for magnesia hydration[J].Sichuan Metallurgy,2013,35(2):58-61.

|

| 15 |

尤士伟,孙荣海.B2O3含量对镁砂抗水化性能的影响[J].耐火与石灰,2008,33(2):18-22.

|

|

YOU Shiwei, SUN Ronghai.Influence of B2O3 content on hydration resistance of magnesia[J].Refractories & Lime,2008,33(2):18-22.

|

| 16 |

桂明玺.添加氧化镍对提高镁砂抗水化性的效果[J].国外耐火材料,2006,31(1):57.

|

|

GUI Mingxi.Effect of adding nickel oxide on improving hydration resistance of magnesia[J].Foreign Refractories,2006,31(1):57.

|

| 17 |

朴明伟.添加柠檬酸对含氧化镁耐火浇注料的抗水化性能影响[J].耐火与石灰,2013,38(1):33-35.

|

|

PIAO Mingwei.Effect of adding citric acid on hydration resistance of refractory castable containing magnesium oxide[J].Refractories & Lime,2013,38(1):33-35.

|

| 18 |

SAKO E Y, BRAULIO M A L, PANDOLFELLI V C.Microstruc⁃

|

|

tural evolution of magnesia⁃based castables containing microsili⁃

|

|

ica[J].Ceramics International,2012,38(7):6027-6033.

|

| 19 |

MURALI K P, RAJESH S, PRAKASH O,et al.Effects of silane coatings in aqueous and non⁃aqueous media on the properties of magnesia filled PTFE laminates[J].Materials Chemistry and Physics,2010,122(2/3):317-320.

|

| 20 |

OIKAWA Y, GOTO Y, NISHIDA M,et al.Preparation of morpholo⁃

|

|

gy⁃controlled fluoroalkyl end⁃capped vinyltrimethoxysilane oligomeric silica/magnesium oxide nanocomposite particles:Development of magnesium oxide nanocomposite particles possessing a water⁃resistance ability[J].Journal of Sol-Gel Science and Technology,2019,89(1):135-147.

|

| 21 |

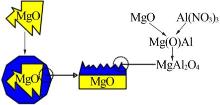

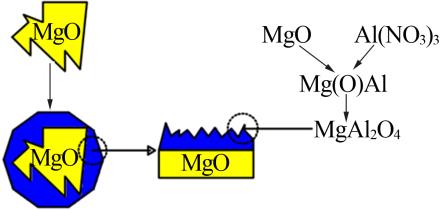

MADEJ D, TYRAŁA K.In situ spinel formation in a smart nano⁃structured matrix for no⁃cement refractory castables[J].Materials,2020,13(6):1403.

|

| 22 |

NASKAR M K, CHATTERJEE M.Magnesium aluminate

|

|

MgAl 2 O4) spinel powders from water⁃based sols[J].Journal of the American Ceramic Society,2005,88(1):38-44.

|

| 23 |

RAHMAT N, YAAKOB Z, PUDUKUDY M,et al.Single step so⁃

|

|

lid⁃state fusion for MgAl 2 O4 spinel synthesis and its influence on the structural and textural properties[J].Powder Technology,2018,329:409-419.

|

|

上接第 89 页)

|

),WANG Guosheng(

),WANG Guosheng( )

)