Inorganic Chemicals Industry ›› 2020, Vol. 52 ›› Issue (12): 80-85.doi: 10.11962/1006-4990.2020-0020

• Chemical Equipment and Design • Previous Articles Next Articles

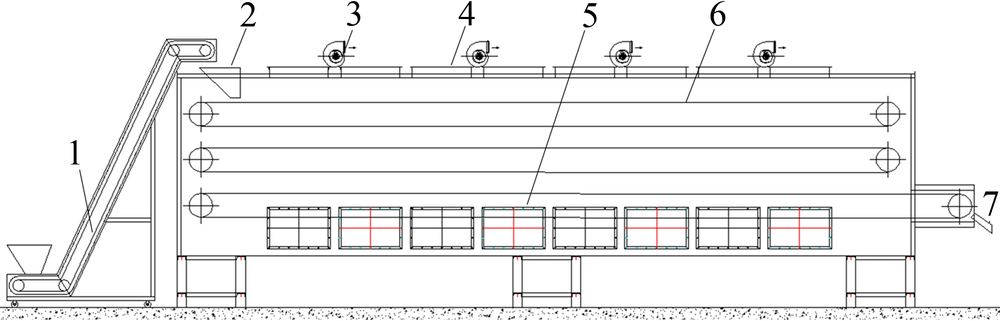

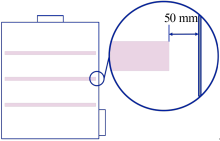

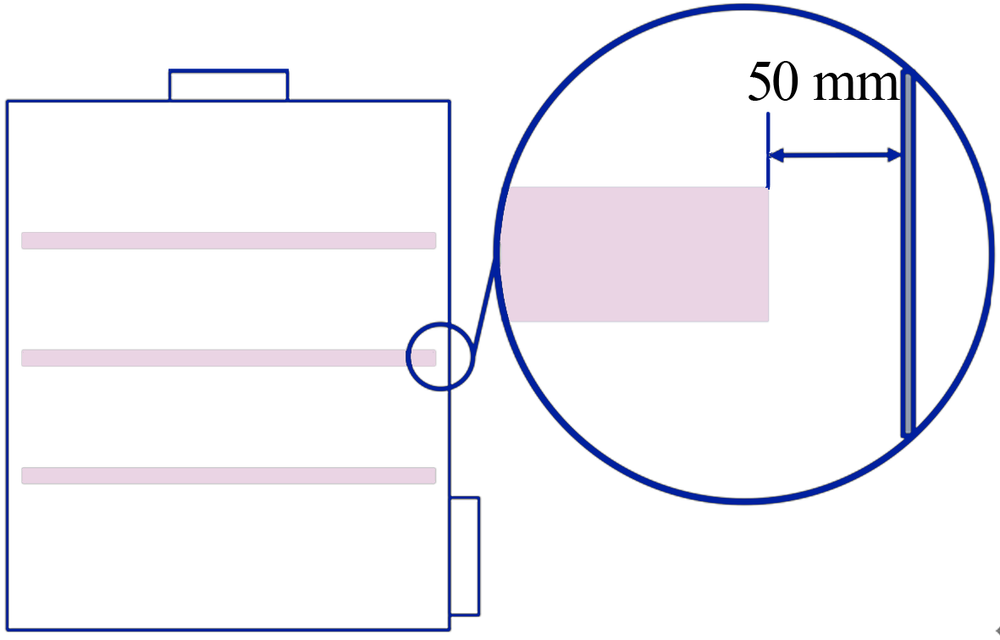

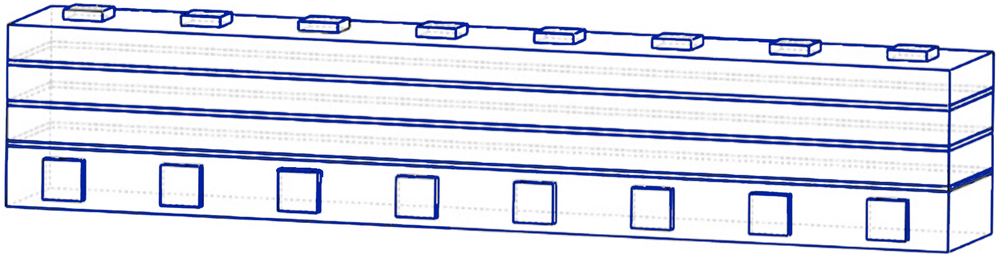

Simulation and improvement of flow field in side-entry wind salt mud drying room

Zhu Guihua1,2,He Weize1,2,Tang Haoting1,2,Yi Shanzhen1,2,Chen Yong1,2

- 1. College of Mechanical and Electrical Engineering,Central South University,Changsha 410083,China

2. Hunan Zhongda Shanshui Environmental Protection Technology Co.,Ltd.