| [1] |

Xu Xinfang,Zhou Xiaoping,Liu Zhengfeng,Li Lei,Chen Hu,Li Changming.

Study on causticization and purification of salt lake lithium ore and recovery of fluorine-containing lithium carbonate

[J]. Inorganic Chemicals Industry, 2020, 52(7): 62-65.

|

| [2] |

Zhang Yan,Zhao Zhenzhong,Ma Zhaohui,Zhao Yancai,Chen Zhiyu,Ma Zhengqiang.

Optimization of process for preparation of battery grade lithium carbonate by carbonization

[J]. Inorganic Chemicals Industry, 2020, 52(3): 68-71.

|

| [3] |

Hu Min,Gong Hanzhang,Wu Huadong,Guo Jia,Zhang Linfeng,Zhou Yuxin.

Preparation of battery-grade lithium carbonate from lithium-containing industrial waste

[J]. Inorganic Chemicals Industry, 2020, 52(3): 80-84.

|

| [4] |

Liu Yuelong,Wang Linlin,Liu Gousheng.

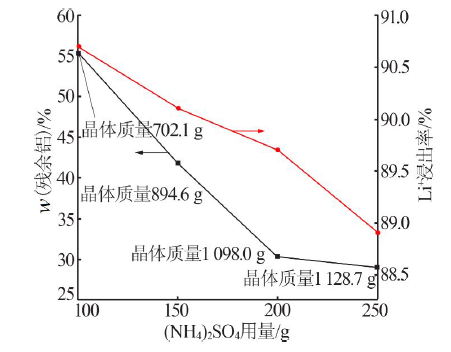

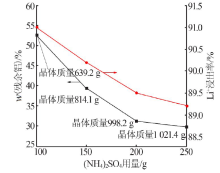

Extraction of rubidium and cerium salts from lithium tail liquid of medium and low grade lithium clay by ammonium sulfate process

[J]. Inorganic Chemicals Industry, 2020, 52(11): 60-63.

|

| [5] |

Chen Jie,Chen Xia.

Crystallization process optimization for preparation of lithium carbonate

[J]. Inorganic Chemicals Industry, 2019, 51(8): 29-32.

|

| [6] |

Liu Guowang,Zhou Xiaojun,Zhang Shichun,Yang Shangming,Dong Shoulong,Li Binshou.

Recycle method of lithium extracted mother solution and phase diagram analysis

[J]. Inorganic Chemicals Industry, 2019, 51(6): 38-40.

|

| [7] |

Yin Jishuai,Sun Wenliang,Hao Rusi,Wang Xiao.

Study on the influence of lithium deposition reaction conditions on purity and impurities of lithium carbonate

[J]. Inorganic Chemicals Industry, 2019, 51(3): 29-33.

|

| [8] |

Hao Ziyang,Yuan Bo,Li Xin,Yi Meigui.

Research on removal mechanism of soluble impurities in lithium concentrate

[J]. Inorganic Chemicals Industry, 2019, 51(3): 49-52.

|

| [9] |

Li Xin1,Yuan Bo2,Yi Meigui1.

Study on removal of trace sulfur impurities from lithium carbonate by hydrothermal method

[J]. Inorganic Chemicals Industry, 2019, 51(11): 28-30.

|

| [10] |

Hao Jiantang,Wen Fengyuan,Li Xia.

Study on extracting lithium from electrolytic aluminum waste residue

[J]. Inorganic Chemicals Industry, 2019, 51(10): 69-71.

|

| [11] |

WANG Yan-Fei, WANG Lei-Xin, XING Hong, YANG Jing, ZHAO Yan-Ping, YANG Li-Bin, ZHU Liang, ZHAO Xiao-Yu, SHA Zuo-Liang, WANG Wen-Hai.

Size and morphology controlling of lithium carbonate in reactive crystallization process

[J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(9): 13-.

|

| [12] |

DENG Shu-Hao, YANG Zi-Xuan, YANG Jia-Yi, YANG Xi, YIN Chong, HAN Jiang, YI Dan-Qing.

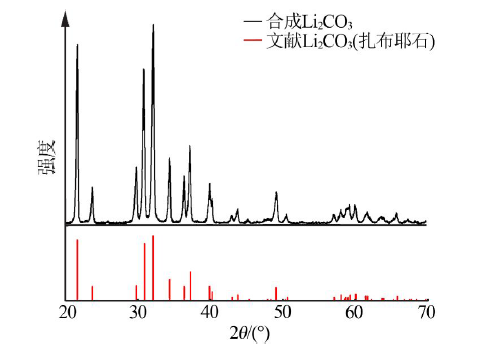

New process for preparation of high purity lithium carbonate from coarse salt in Zabuye Salt Lake

[J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(4): 26-.

|

| [13] |

TAO Zhen-Qi-1, ZHANG Zhi-Qiang-1, BI Qiu-Yan-1, NIU Hui-Zhe-1, LI Xiao-Song-2.

Study on preparation of lithium carbonate via reactive crystallization

from lithium chloride and sodium carbonate

[J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(11): 25-.

|

| [14] |

PENG Qiu-Hua.

Production of battery-grade lithium carbonate from carbonate-type

lithium concentrate by deep carbonization method

[J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(1): 38-.

|

| [15] |

LI Yan-Ru, ZHU Liang, YUAN Jian-Jun, SHA Zuo-Liang, YANG Mei-Jie, ZUO Yue-Hua.

Research on purifying process of coarse lithium carbonate

[J]. INORGANICCHEMICALSINDUSTRY, 2013, 45(8): 15-.

|

),Wang Linlin2,Liu Yuelong3(

),Wang Linlin2,Liu Yuelong3( )

)