| 1 |

OLIVIER S S, SEPPALA L, GILMORE K.Optical design of the LSST camera[C]//Advanced Optical and Mechanical Technologies in Telescopes and Instrumentation.Washington,D.C.:SPIE,2008,7018:892-900.

|

| 2 |

SUN Wenwen, ZHU Yuman, MARCEAU R,et al.Precipitation strengthening of aluminum alloys by room⁃temperature cyclic plasticity[J].Science,2019,363(6430):972-975.

|

| 3 |

MAYÉN J, GALLEGOS-MELGAR A, MERCADO-LEMUS V H,et al.Control parameters correlation by multiple linear robust regression for the design of heat treatments for Al-6063 alloy[J].Experimental Techniques,2019,43(1):91-103.

|

| 4 |

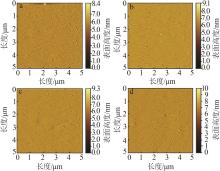

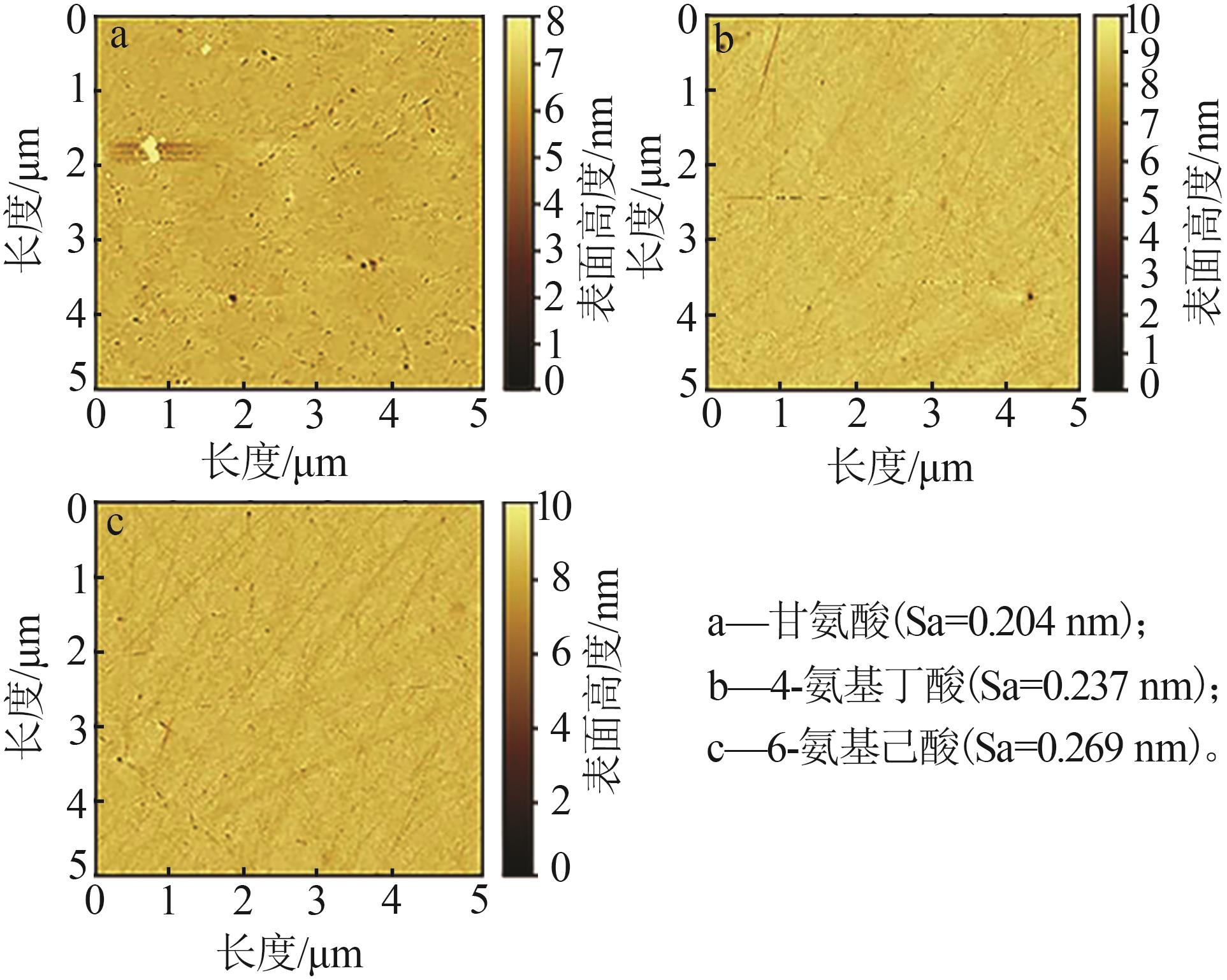

宋晓明,张振宇,刘杰,等.5083铝合金绿色化学机械抛光液对表面粗糙度的影响及机理分析[J].表面技术,2022,51(5):345-353.

|

|

SONG Xiaoming, ZHANG Zhenyu, LIU Jie,et al.Effect and mechanism analysis of green chemical mechanical slurry on surface roughness of 5083 aluminum alloy[J].Surface Technology,2022,51(5):345-353.

|

| 5 |

雷红,雒建斌,张朝辉.化学机械抛光技术的研究进展[J].上海大学学报(自然科学版),2003,9(6):494-502.

|

|

LEI Hong, LUO Jianbin, ZHANG Chaohui.Advances in chemical mechanical polishing[J].Journal of Shanghai University(Natural Science Edition),2003,9(6):494-502.

|

| 6 |

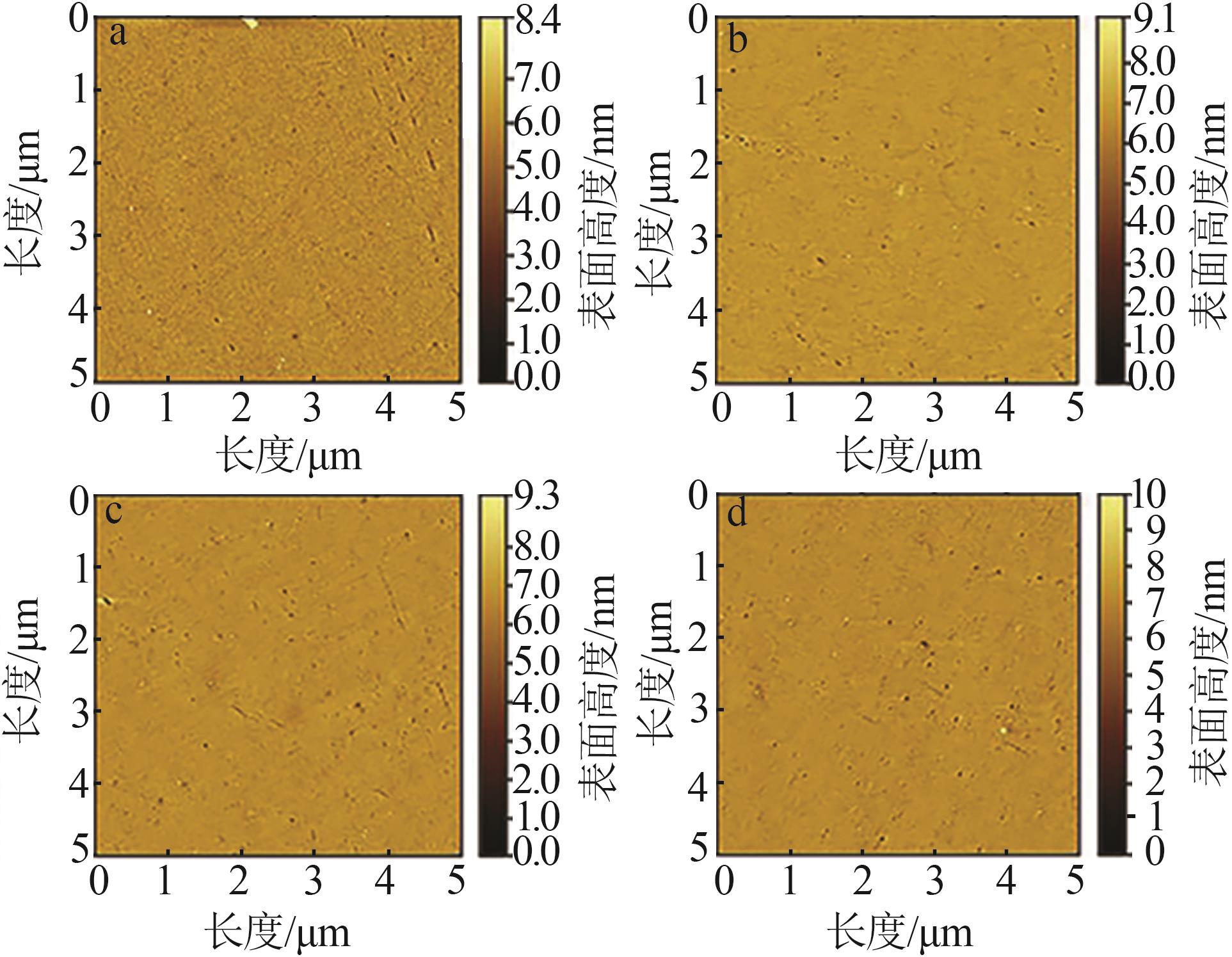

LIU Ping, WANG Yongguang, ZHAO Yongwu,et al. In situ electrochemical behavior of aluminum chemical mechanical polishing at low down pressure in environmentally friendly and weakly alkaline slurry[J].ECS Journal of Solid State Science and Technology,2018,7(11):P698-P705.

|

| 7 |

KUO Hongshi, TSAI W T.Effects of alumina and hydrogen peroxide on the chemical⁃mechanical polishing of aluminum in phosphoric acid base slurry[J].Materials Chemistry and Physics,2001,69:53-61.

|

| 8 |

LIU Shijie.A review on protein oligomerization process[J].International Journal of Precision Engineering and Manufacturing,2015,16(13):2731-2760.

|

| 9 |

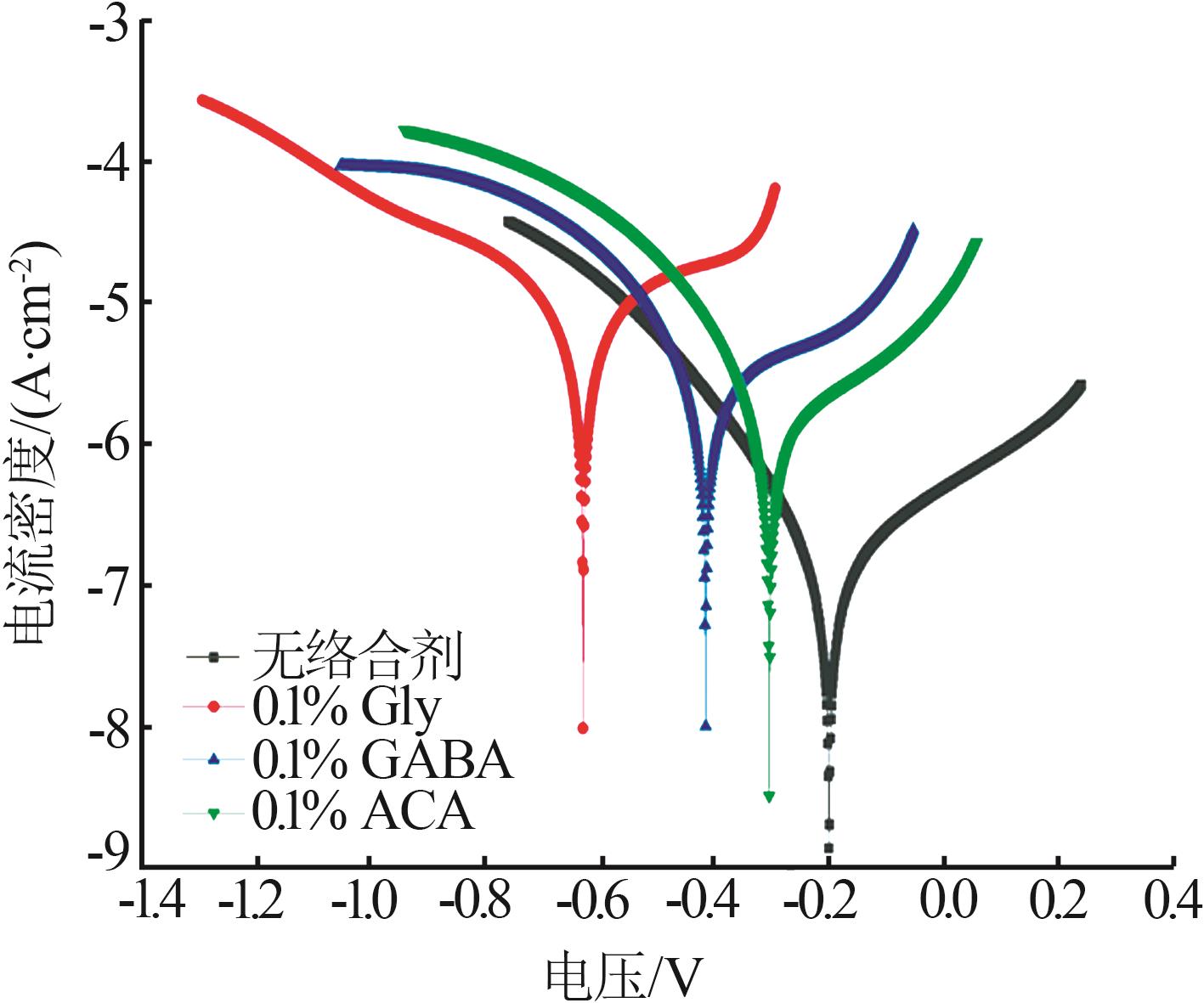

WANG Zhi, SUN Ming, NIU Xinhuan,et al.Effect of pH value and glycine in alkaline CMP slurry on the corrosion of aluminum by electrochemical analysis[J].ECS Journal of Solid State Science and Technology,2019,8(6):P332-P340.

|

| 10 |

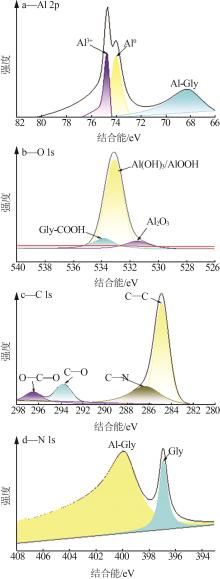

SUN Ping, WANG Yongguang, LIU Ping,et al.Synergetic effect of 1,2,4-triazole and glycine on chemical mechanical planarization of aluminum at low polishing pressure in an eco⁃friendly slurry[J].ECS Journal of Solid State Science and Technology,2020,9(3):034003.

|

| 11 |

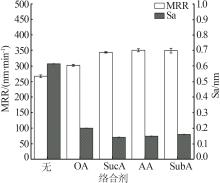

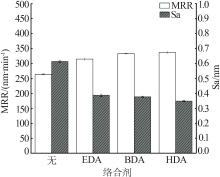

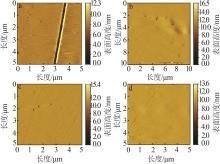

朱玉广,王永光,钮市伟,等.低压力下环保型络合剂和氧化剂对铝合金化学机械抛光的影响[J].金刚石与磨料磨具工程,2020,40(1):74-78.

|

|

ZHU Yuguang, WANG Yongguang, NIU Shiwei,et al.Effect of environmental friendly complexing agent and oxidant on CMP of aluminium alloy under low pressure[J].Diamond & Abrasives Engineering,2020,40(1):74-78.

|

| 12 |

LI Mengqi, SUN Ming, MA Zhongchen.Study on removal rate and mechanism of copper CMP by complexing agent[J].Applied Che⁃ mical Industry,2023,52(01):34-38.

|

| 13 |

杨云点,王胜利,王辰伟,等.不同络合剂与pH对钴CMP去除速率的影响[J].半导体技术,2020,45(7):543-549.

|

|

YANG Yundian, WANG Shengli, WANG Chenwei,et al.Effects of different complexing agents and pH values on cobalt removal rate in CMP[J].Semiconductor Technology,2020,45(7):543- 549.

|

| 14 |

CHEN Guomei, DU Chunkuan, NI Zifeng,et al.Effect of complexing agent on chemical⁃mechanical polishing of 316L stainless steel[J].Diamond and Abrasives Engineering,2022,42(6):753-759.

|

| 15 |

熊伟,白林山,储向峰,等.络合剂对蓝宝石晶片化学机械抛光的影响[J].机械科学与技术,2014,33(7):1027-1030.

|

|

XIONG Wei, BAI Linshan, CHU Xiangfeng,et al.Effect of chelating agent on chemical mechanical polishing quality of sapphi⁃re[J].Mechanical Science and Technology for Aerospace Engineering,2014,33(7):1027-1030.

|

| 16 |

LIU Jinwei, JIANG Liang, WU Hanqiang,et al.Performance of carboxyl groups in chemical mechanical polishing of GCr15 bearing steel:Effects of carbon chain length and pH[J].Tribology Letters,2021,69(4):161.

|

| 17 |

ZHOU Jiakai, NIU Xinhuan, YANG Chenghui,et al.Surface action mechanism and planarization effect of sarcosine as an auxiliary complexing agent in copper film chemical mechanical polishing[J].Applied Surface Science,2020,529:147109.

|

| 18 |

ZHANG Lifei, LU Xinchun, BUSNAINA A A.The role of carboxylic acids on nanoparticle removal in post CMP cleaning process for cobalt interconnects[J].Materials Chemistry and Physics,2022,275:125199.

|

| 19 |

LI Tao, SUN Haoyang, WANG Daiqi,et al.High⁃performance chemical mechanical polishing slurry for aluminum alloy using hybrid abrasives of zirconium phosphate and alumina[J].Applied Surface Science,2021,537:147859.

|

| 20 |

HELAL N H, BADAWY W A.Environmentally safe corrosion inhibition of Mg-Al-Zn alloy in chloride free neutral solutions by amino acids[J].Electrochimica Acta,2011,56(19):6581- 6587.

|

), LI Yanpei1,2, RUI Yichuan1(

), LI Yanpei1,2, RUI Yichuan1( ), ZHANG Zefang1,2(

), ZHANG Zefang1,2( )

)