Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (12): 26-35.doi: 10.19964/j.issn.1006-4990.2023-0209

• Reviews and Special Topics • Previous Articles Next Articles

Research progress of trivalent chromium electrodeposition process

TIAN Yu1( ), ZHANG Zheng1, ZHANG Xingran1(

), ZHANG Zheng1, ZHANG Xingran1( ), CHEN Jie1, WANG Yan1, PENG Hao2

), CHEN Jie1, WANG Yan1, PENG Hao2

- 1. College of Chemistry and Chemical Engineering, Chongqing University of Technology, Chongqing 400054, China

2. College of Chemistry and Chemical Engineering, Yangtze Normal University, Chongqing 408100, China

-

Received:2023-04-11Online:2023-12-10Published:2023-12-14 -

Contact:ZHANG Xingran E-mail:1184417240@qq.com;zhangxingran@cqut.edu.cn

CLC Number:

Cite this article

TIAN Yu, ZHANG Zheng, ZHANG Xingran, CHEN Jie, WANG Yan, PENG Hao. Research progress of trivalent chromium electrodeposition process[J]. Inorganic Chemicals Industry, 2023, 55(12): 26-35.

share this article

Table 1

Composition and main functions ofchromium plating solution[28-31]"

| 镀液组成 | 主要作用 | 常见化学药品 |

|---|---|---|

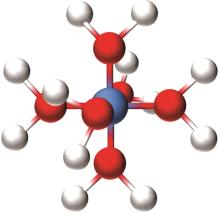

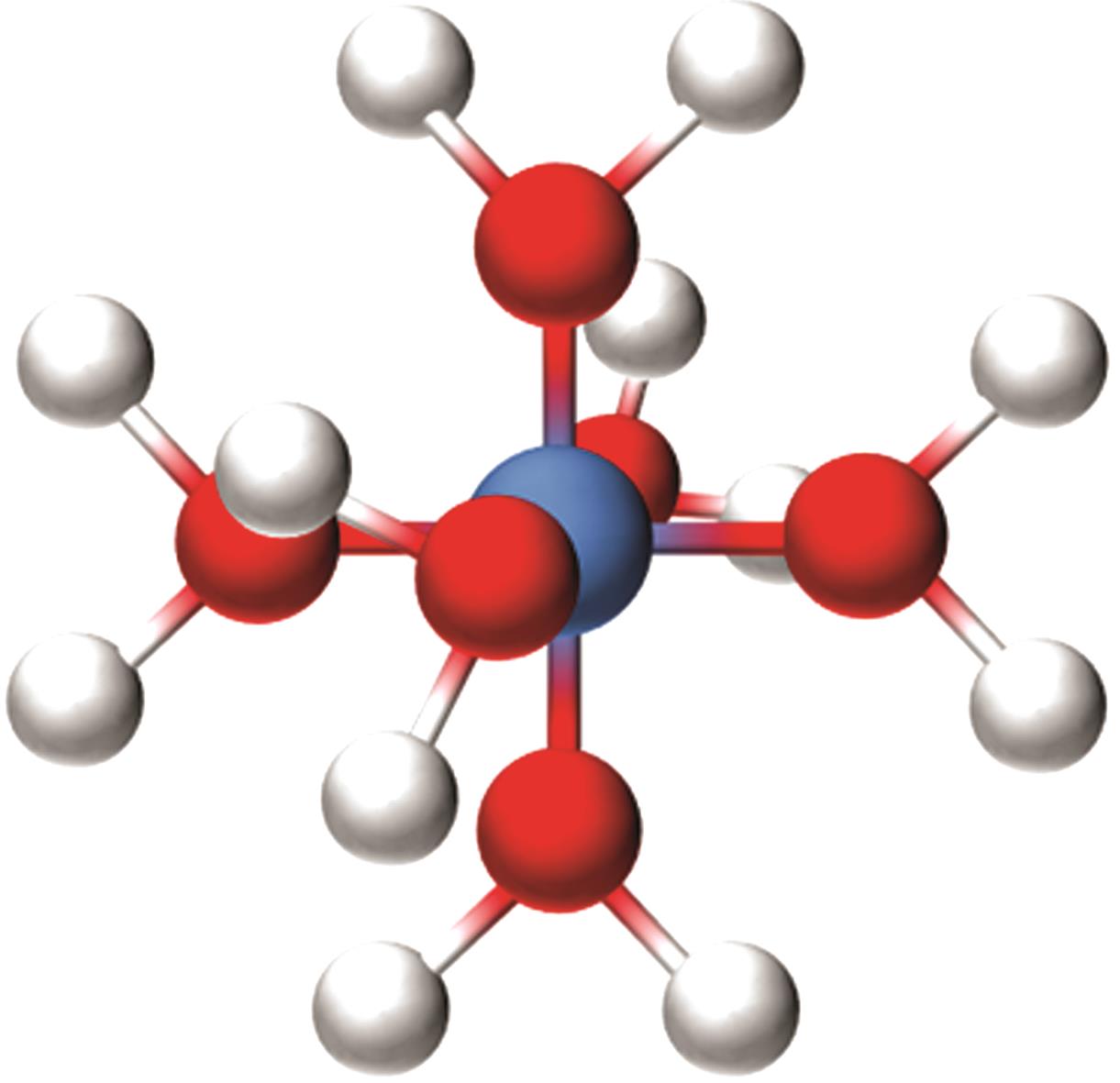

| 主盐 | 作为铬镀液中Cr3+的来源 | CrCl3、Cr2(SO4)3、CrF3、Cr (HCOO)3等 |

| 配位剂 | 与镀液中Cr3+形成配位体 | 甲酸盐、乙酸盐、草酸 盐、柠檬酸盐等 |

| 缓冲剂 | 稳定镀液中pH,使之维持在合适的范围 | H3BO3、醋酸、NH4+、铝盐等 |

| 添加剂 | 防止阳极产生有毒气体;抑制 阳极产生Cr6+;增加镀层光亮区面积;可分为抗氧化剂、阻氢 剂、促进剂、光亮剂、稳定剂等 | 溴化物、铵盐、醛类、聚乙二醇等 |

| 导电盐 | 增强镀液的导电性;降低电沉 积过程能耗 | KCl、NH4Cl等 |

| 表面活性剂 | 降低镀液表面张力;保证镀层 厚度均匀 | 十二烷基苯磺酸钠、十二烷基硫酸钠、OP-10等 |

| 其他(多元络合剂) | 增加镀层厚度;增强镀液稳定 性 | 甲酸盐-乙酸盐-氨基乙酸、硫酸盐-酒石酸盐、甲酸胺-尿素、草酸盐-乙二胺-四乙酸二钠等 |

Table 2

Kinds and functions of additives inchromium plating solution"

| 添加剂 | 主要作用 | 添加效果 |

|---|---|---|

| F-[ | 防止阳极产生有毒气体 | 阳极最终无有毒气体产生 |

| 间二氮茂环化合物[ | 抑制阳极产生Cr6+ | 阳极产生微量Cr6+ |

| 苯甲酸磺酰亚胺[ | 提高电流密度、沉积效率 | 最佳质量浓度为1.5g/L时,电流密度达最大 |

| 聚氧乙烯辛烷基酚醚和丙三醇[ | 作为润湿剂 | 获得的镀层厚度均匀、镀层厚度适中 |

| 聚乙二醇[ | 抑制析氢反应 | 析氢反应减少 |

| 尿素[ | 提高电沉积效率 | 尿素有效提高铬沉积的过电位,所得镀层表面无明显裂痕和气孔 |

| 含硫添加剂[ | 改善镀层外观 | 获得的镀层外观良好、色泽光亮 |

| 18-冠醚-6[ | 使所得镀层的颗粒变大 | 镀层中铬含量有所提高,铬镀层的厚度达到72.5 μm,电流效率为42.3% |

Table 3

Industrial application of electroplating process in some enterprises"

| 公司 | 国家 | 主要工艺 | 工业化应用 | |

|---|---|---|---|---|

| Albring&Wilson 公司 | 英国 | Alecra3三价铬电镀工艺 | 标志三价铬电镀实现工业化 | US3766028 |

| OKUNO CHEM IND CO、NIPPON CHEMICAL IND | 日本 | 引入Aleera3三价铬电镀工艺,解决单槽硫酸盐、氯化物混合浴和双槽硫酸浴常见问题 | 汽车、手机、日常用品等需进行装饰性电镀铬的生产领域 | 日本专利:昭56-52103 |

| 安美特Atotech | 美国&德国 | 三价铬镀铬优化工艺 | AM-529—适应于镀锌层上的环保型三价铬钝化 | US5294326 |

| 南京大地冷冻食品有限公司 | 中国 | 硫酸盐体系镀液中加入脂肪酸聚氧乙烯脂肪酸酯、脂肪酸聚氧乙烯醚类物质作为光亮剂 | 获得超过5 μm厚的光亮铬镀层,具良好的装饰性能 | CN201210420094.9 |

| 比亚迪股份有限公司 | 中国 | 邻苯甲酰磺酰亚胺、水溶性磺基丁二酸盐等作为添加剂 | 电流密度大幅提高,克服了现有全硫酸盐型三价铬电镀液镀层光亮区电流密度范围小的缺点 | CN200710086887.0 |

| 佛山昭信金属制品企业 | 中国 | 在三价铬镀槽前依次连接镍、电镀槽、多级逆流漂洗槽和超声波清洗槽 | 有效减少电镀过程中杂质金属离子的带入,提高槽液的净化度和产品质量的稳定性 | CN200820044086.8 |

| 广东达志环保科技股份有限公司 | 中国 | 将纳米二氧化硅、氧化铝复配物作为镀液添加剂 | 三价铬镀层的耐蚀性有效提高,生产工件的整体耐磨性能提升 | CN201110352605.3 |

| 广州超邦化工有限公司 | 中国 | 改善镀层耐蚀性工艺,将各层依次逐层电镀于金属基体表面 | 满足目前汽车行业铜加速乙酸盐雾实验48 h的测试需求 | CN201520829650.7 |

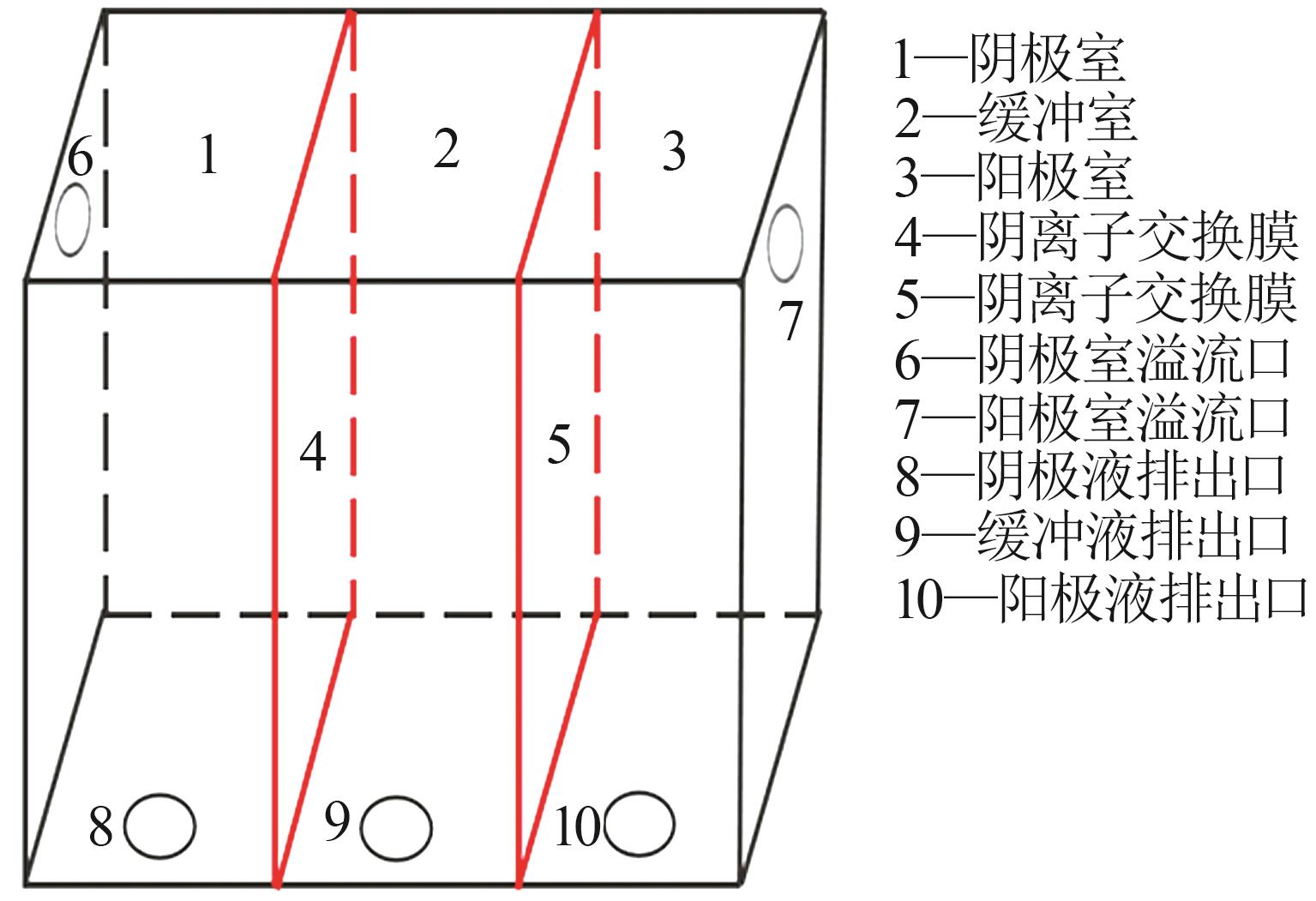

| 广州二轻所 | 中国 | 在硫酸盐三价铬电镀和钛基涂层阳极两方面进行研发工艺 | 镀层产品及钛基涂层已面市销售 | CN200910042266.1 |

| 湖南工业大学 | 中国 | 氯化铬作为主盐,改善电镀液性能 | 获得硬度高、色泽光亮、无裂纹的镀层产品 | CN103993336A |

| 1 | 邓正平, 田志斌, 詹益腾, 等. 代六价铬电镀现状及趋势[J]. 电镀与涂饰, 2020, 39(7):440-443. |

| DENG Zhengping, TIAN Zhibin, ZHAN Yiteng, et al. Current status and development trends of alternative processes to hexavalent chromium electroplating[J]. Electroplating & Finishing, 2020, 39(7):440-443. | |

| 2 |

ZHANG Bo, FENG Haitao, LIN Feng, et al. Superhydrophobic surface fabricated on iron substrate by black chromium electrodeposition and its corrosion resistance property[J]. Applied Surface Science, 2016, 378:388-396.

doi: 10.1016/j.apsusc.2016.04.004 |

| 3 | KARTHIKEYAN S, JEEVA P A, RAJA K, et al. An eco-friendly process on the improvement of hardness and corrosion resistance characteristics of trivalent hard chromium electrodeposition[J]. Materials Today:Proceedings, 2018, 5(5):13085-13089. |

| 4 | 徐凌云. 电沉积技术在锂金属二次电池及三价铬硬铬电镀中的应用研究[D]. 武汉: 武汉大学, 2021. |

| XU Lingyun. Application research of electrodeposition technology in lithium metal secondary battery and trivalent chromium hard chromium electroplating[D]. Wuhan: Wuhan University, 2021. | |

| 5 | 周磊. 环保型三价铬镀硬铬的研究[D]. 赣州: 江西理工大学, 2010. |

| ZHOU Lei. Study on environment-friendly trivalent chromium plating with hard chromium[D]. Ganzhou: Jiangxi University of Science and Technology, 2010. | |

| 6 |

BAYRAMOGLU M, ONAT B, GEREN N. Statistical optimization of process parameters to obtain maximum thickness and brightness in chromium plating[J]. Journal of Materials Processing Technology, 2008, 203(1/2/3):277-286.

doi: 10.1016/j.jmatprotec.2007.09.063 |

| 7 | 张曼珂, 明庭云, 周启运, 等. 铬金属的电沉积研究进展[J]. 电镀与精饰, 2019, 41(3):28-30. |

| ZHANG Manke, MING Tingyun, ZHOU Qiyun, et al. Research progress of chromium plating[J]. Plating & Finishing, 2019, 41(3):28-30. | |

| 8 | HAY W W. Exploring the electromagnetic spectrum[M]// Experimenting on a small planet. Berlin,Heidelberg: Springer, 2013:238-258. |

| 9 |

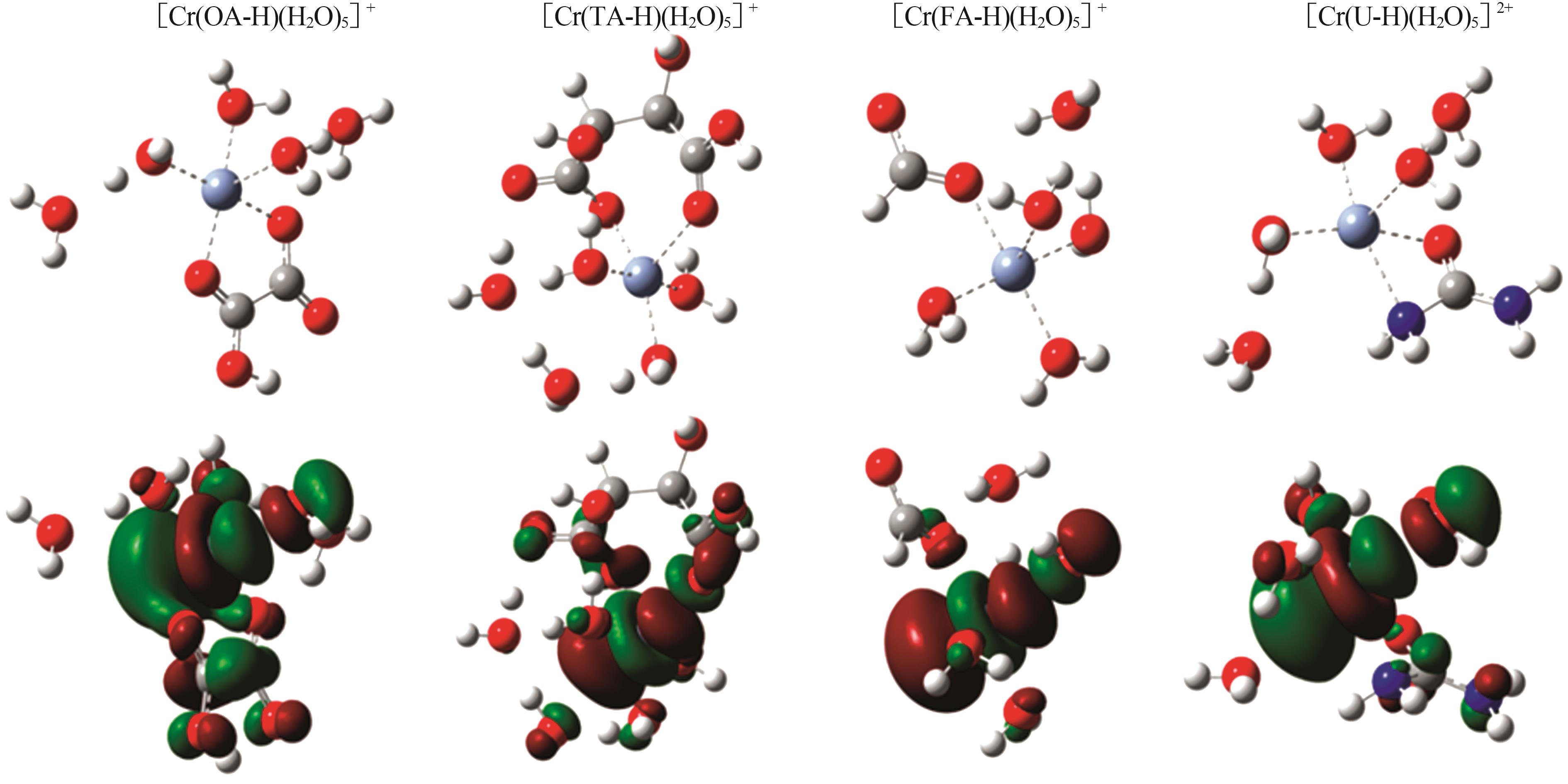

ZENG Zhixiang, SUN Yaling, ZHANG Junyan. The electrochemical reduction mechanism of trivalent chromium in the presence of formic acid[J]. Electrochemistry Communications, 2009, 11(2):331-334.

doi: 10.1016/j.elecom.2008.11.055 |

| 10 | 陈棽, 朱莎莎, 李巧云, 等. 三价铬离子阴极电沉积机理的探讨[J]. 闽南师范大学学报(自然科学版), 2016(1):80-82. |

| CHEN Chen, ZHU Shasha, LI Qiaoyun, et al. Cathodic electroreduction mechanistic study on trivalent chromium ions in an aqueous solution[J]. Journal of Minnan Normal University(Natural Science), 2016(1):80-82. | |

| 11 |

BIKULČIUS G, ČEŠUNIENĖ A, SELSKIENĖ A, et al. Dry sliding tribological behavior of Cr coatings electrodeposited in trivalent chromium sulphate baths[J]. Surface and Coatings Technology, 2017, 315:130-138.

doi: 10.1016/j.surfcoat.2017.01.076 |

| 12 | 李烨, 高云芳, 徐新, 等. 尿素对甲酸盐体系三价铬电沉积的作用机理[J]. 电镀与涂饰, 2013, 32(9):5-8. |

| LI Ye, GAO Yunfang, XU Xin, et al. Mechanism of the effect of urea on electrodeposition of trivalent chromium from Cr(Ⅲ)-formate plating system[J]. Electroplating & Finishing, 2013, 32(9):5-8. | |

| 13 |

SONG Y B, CHIN D T. Current efficiency and polarization behavior of trivalent chromium electrodeposition process[J]. Electrochimica Acta, 2002, 48(4):349-356.

doi: 10.1016/S0013-4686(02)00678-3 |

| 14 |

DEL PIANTA D, FRAYRET J, GLEYZES C, et al. Determination of the chromium(Ⅲ) reduction mechanism during chromium electroplating[J]. Electrochimica Acta, 2018, 284:234-241.

doi: 10.1016/j.electacta.2018.07.114 |

| 15 | HSIEH A, EE Y H, CHEN K N. Electrochemistry of chromium deposition from thiocyanato trivalent system[J]. Metal Finishing, 1993, 91:53-57. |

| 16 | 舒绪刚, 廖列文, 何湘柱, 等. 氯化物水溶液体系三价铬电沉积机理研究[J]. 表面技术, 2010, 39(2):1-4,13. |

| SHU Xugang, LIAO Liewen, HE Xiangzhu, et al. The mechanism of trivalent chromium electrodeposition and electrocrystallization from trivalent chromium in chloride system[J]. Surface Technology, 2010, 39(2):1-4,13. | |

| 17 | 张鹏飞, 梅军云. 三价铬硬铬电镀及镀层性能镀层性能研究[J]. 中国设备工程, 2022(14):140-142. |

| ZHANG Pengfei, MEI Junyun. Study on trivalent chromium hard chromium electroplating and coating properties[J]. China Plant Engineering, 2022(14):140-142. | |

| 18 |

ENDRES F, BUKOWSKI M, HEMPELMANN R, et al. Electrodeposition of nanocrystalline metals and alloys from ionic liquids[J]. Angewandte Chemie International Edition, 2003, 42(29):3428-3430.

doi: 10.1002/anie.v42:29 |

| 19 |

ZENG Zhixiang, ZHANG Yingxin, ZHAO Wenjie, et al. Role of complexing ligands in trivalent chromium electrodeposition[J]. Surface and Coatings Technology, 2011, 205(20):4771-4775.

doi: 10.1016/j.surfcoat.2011.04.019 |

| 20 | 朱莎莎. 硫酸铬/草酸钠体系中三价铬阴极电沉积过程的研究[D]. 漳州: 闽南师范大学, 2016. |

| ZHU Shasha. Study on trivalent chromium cathodic electrodeposition process in chromium sulfate/sodium oxalate system[D]. Zhangzhou: Minnan Normal University, 2016. | |

| 21 | XU Lingyun, PI Liu, DOU Yiheng, et al. Electroplating of thick hard chromium coating from a trivalent chromium bath containing a ternary complexing agent:A methodological and mechanistic study[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(41):15540-15549. |

| 22 |

LEE J Y, KIM M, KWON S C. Effect of polyethylene glycol on electrochemically deposited trivalent chromium layers[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(4):819-823.

doi: 10.1016/S1003-6326(08)60357-X |

| 23 | YAGI S, OSHIMA H, MURASE K, et al. Alternating pulsed electrolysis for Fe-Cr surface alloying of conventional carbon steel[J]. ECS Transactions, 2008, 11(18):23-34. |

| 24 | PEARSON T, HANDY S. Process for plating chromium from a trivalent chromium plating bath: US, 7780840[P]. 2010-08-24. |

| 25 | 吴扬, 崔楠, 张颖. 碳钢基体环保型三价铬镀铬工艺及镀铬层性能[J]. 电镀与环保, 2019, 39(5):1-4. |

| WU Yang, CUI Nan, ZHANG Ying. Eco-friendly trivalent chromium plating process on carbon steel substrate and properties of the chromium coatings[J]. Electroplating & Pollution Control, 2019, 39(5):1-4. | |

| 26 |

ADACHI K, KITADA A, FUKAMI K, et al. Crystalline chromium electroplating with high current efficiency using chloride hydrate melt-based trivalent chromium baths[J]. Electrochimica Acta, 2020, 338:135873.

doi: 10.1016/j.electacta.2020.135873 |

| 27 | 梁智鹏, 王一雍, 金辉, 等. Ni-Co/ZrO2复合镀层的制备与研究[J]. 电镀与环保, 2019, 39(1):13-16. |

| LIANG Zhipeng, WANG Yiyong, JIN Hui, et al. Preparation and investigation of Ni-Co/ZrO2 composite coating[J]. Electroplating & Pollution Control, 2019, 39(1):13-16. | |

| 28 | 周琳燕, 古雅菁, 欧阳小琴, 等. 三价铬电镀工艺研究现状及展望[J]. 电镀与精饰, 2015, 37(8):14-18. |

| ZHOU Linyan, GU Yajing, OUYANG Xiaoqin, et al. Review on the trivalent chromium plating process[J]. Plating & Finishing, 2015, 37(8):14-18. | |

| 29 |

QI Jiantao, ŚWIATOWSKA J, SKELDON P, et al. Chromium valence change in trivalent chromium conversion coatings on aluminium deposited under applied potentials[J]. Corrosion Science, 2020, 167:108482.

doi: 10.1016/j.corsci.2020.108482 |

| 30 |

LEIMBACH M, TSCHAAR C, SCHMIDT U, et al. Electrochemical characterization of chromium deposition from trivalent solutions for decorative applications by EQCM and near-surface pH measurements[J]. Electrochimica Acta, 2018, 270:104-109.

doi: 10.1016/j.electacta.2018.03.011 |

| 31 | BARAL A, ENGELKEN R. Modeling,optimization and comparative analysis of trivalent electrodeposition from aqueous glycine and formic acid baths[J]. Elec-trochemical Society, 2005, 152(7):504-512. |

| 32 | 舒莉. 多元络合剂体系三价铬电镀工艺及其机理的研究[D]. 福州: 福州大学, 2014. |

| SHU Li. Technology and mechanism of trivalent chromium electroplating in multi complexing system[D]. Fuzhou: Fuzhou University, 2014. | |

| 33 | 赵焕, 乔永莲, 董宇, 等. 国内三价铬电镀专利综述[J]. 当代化工, 2019, 48(2):399-402. |

| ZHAO Huan, QIAO Yonglian, DONG Yu, et al. Summary on patents of trivalent chromium electroplating process in China[J]. Contemporary Chemical Industry, 2019, 48(2):399-402. | |

| 34 | 孙浩原. 铬电沉积的研究与进展[J]. 辽宁化工, 2020, 49(7):879-880,888. |

| SUN Haoyuan. Research and progress of chromium electrodeposition[J]. Liaoning Chemical Industry, 2020, 49(7):879-880, 888. | |

| 35 | 蔡再华, 程西川, 吴正松. 一种高浓度硫酸铬—氟化铵三价铬电镀液及制备方法: 中国, 102443825B[P]. 2014-03-26. |

| 36 | JUNG M, LEE G, CHOI J. Electrochemical plating of Cu-Sn alloy in non-cyanide solution to substitute for Ni undercoating layer[J]. Electrochim Acta, 2017(241):229-236. |

| 37 | SNYDER D. Distinguishing trivalent chromium deposits by co-lor[J]. Plating and Surface Finishing, 2003, 90:34-39. |

| 38 | 殷恒波, 漆琳, 尹常庆, 等. 三价铬电镀液及其制备以及应用其电镀不锈钢工件的方法: 中国, 101397685A[P]. 2009-04-01. |

| 39 |

VAN PHUONG N, KWON S C, LEE J Y, et al. Mechanistic study on the effect of PEG molecules in a trivalent chromium electrodeposition process[J]. Microchemical Journal, 2011, 99(1):7-14.

doi: 10.1016/j.microc.2011.02.017 |

| 40 | 王伟. 硫酸盐溶液体系三价铬镀铬添加剂及动力学研究[D]. 广州: 华南理工大学, 2014. |

| WANG Wei. Study on additives and kinetics of trivalent chromium plating from sulfate electrolyte[D]. Guangzhou: South China University of Technology, 2014. | |

| 41 |

王怡捷, 钮东方, 张新胜. 离子液体中18-冠醚-6添加剂对三价铬电沉积的影响[J]. 电化学, 2020, 26(6):859-867.

doi: 10.13208/j.electrochem.191009 |

|

WANG Yijie, NIU Dongfang, ZHANG Xinsheng. Effect of 18-crown-6 additive on chromium electrodeposition in ionic li-quid[J]. Journal of Electrochemistry, 2020, 26(6):859-867.

doi: 10.13208/j.electrochem.191009 |

|

| 42 | 闫慧. 硫酸盐体系电沉积功能性三价铬工艺、性能与机理研究[D]. 厦门: 厦门大学, 2017. |

| YAN Hui. Study on electrodeposition process,characterization and mechanism of functional trivalent chromium in sulfate ba-th[D]. Xiamen: Xiamen University, 2017. | |

| 43 |

TREJO J, TOLOSA R, RUIZ N, et al. Comparative study of the main properties associated with thin layers of coatings with the cobalt-chromium-tungsten alloy(stellite) and hard chromium plating used as reinforcements for wood sawing[J]. Mechanics of Materials, 2021, 152:103637.

doi: 10.1016/j.mechmat.2020.103637 |

| 44 | 钮 挺, 赵韦韦. 国内外三价铬电镀发展专利综述[J]. 机电技术专用, 2019(2):146. |

| 45 | COOPER C J. Electrowinning of Chromium Metal[P]. US,3766028A, 1973-10-16. |

| 46 |

VINCENT J B. Recent developments in the biochemistry of chromium(Ⅲ)[J]. Biological Trace Element Research, 2004, 99(1):1-16.

doi: 10.1385/BTER:99:1-3 |

| 47 | 张鉴, 华青松, 郑莉莉, 等. 质子交换膜燃料电池建模综述[J]. 电源技术, 2019, 43(6):1051-1053,1082. |

| ZHANG Jian, HUA Qingsong, ZHENG Lili, et al. Review of modeling of proton exchange membrane fuel cell[J]. Chinese Journal of Power Sources, 2019, 43(6):1051-1053,1082. | |

| 48 |

PARK J E, KANG S Y, OH S H, et al. High-performance anion-exchange membrane water electrolysis[J]. Electrochimica Acta, 2019, 295:99-106.

doi: 10.1016/j.electacta.2018.10.143 |

| 49 |

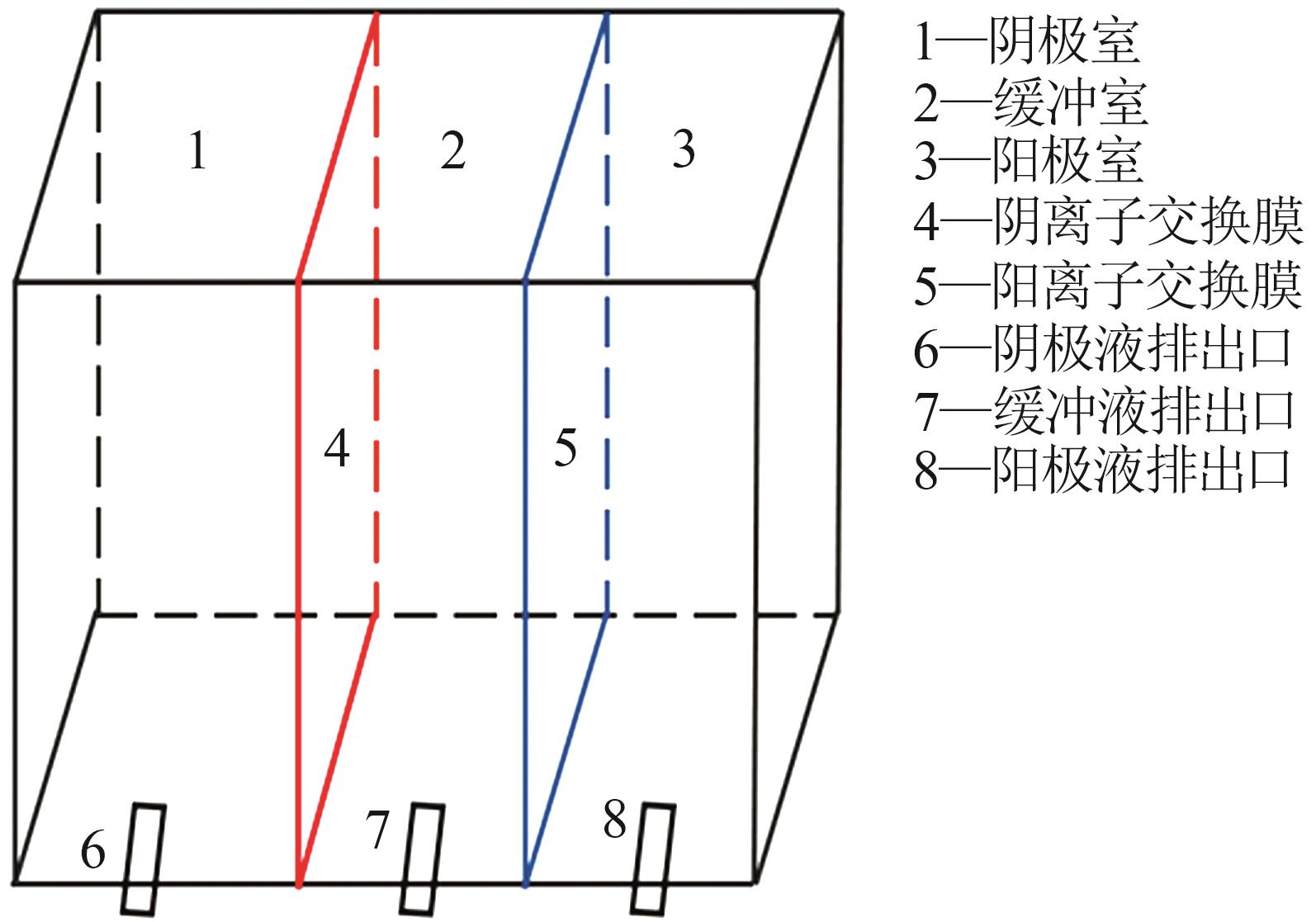

QIU Xuejing, HU Huiping, HU Fang, et al. Simultaneous recovery of copper(Ⅱ) from two different feed solutions based on a three-compartment module with selective polymer inclusion membranes[J]. Hydrometallurgy, 2019, 188:64-72.

doi: 10.1016/j.hydromet.2019.06.007 |

| 50 | 陈文超. 三室双膜电解槽电解高纯铬[D]. 鞍山: 辽宁科技大学, 2008. |

| CHEN Wenchao. Electroanalysis pure Cr using two membrane three room electroplate[D]. Anshan: University of Science and Technology Liaoning, 2008. | |

| 51 | 阳伦庄. 电解法制备高纯金属铬的工艺研究[D]. 长沙: 中南大学, 2011. |

| YANG Lunzhuang. The research of technology on high-purity chromium preparation by electrolytic method[D]. Changsha: Central South University, 2011. | |

| 52 | 熊能. 铬铁矿高效浸出及制备金属铬的工艺研究[D]. 重庆: 重庆理工大学, 2022. |

| XIONG Neng. Theresearch on high-efficiency leaching of chromite and preparation pross of chrome metal[D]. Chongqing: Chongqing University of Technology, 2022. |

| [1] | HUA Man, CHE Ying, YANG Hexiong, WEN Qihao. Determination method of trivalent chromium in iron chromium flow electrolytes [J]. Inorganic Chemicals Industry, 2024, 56(1): 121-125. |

| [2] | JI Zhu. Development direction of chromium salts:Development of new chromium products and uses [J]. INORGANICCHEMICALSINDUSTRY, 2014, 46(10): 1-. |

| [3] | JI Zhu. Preparation of trivalent chromium compounds from chromite by acid-leaching technique [J]. INORGANICCHEMICALSINDUSTRY, 2012, 44(12): 1-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||