Inorganic Chemicals Industry ›› 2019, Vol. 51 ›› Issue (5): 92-96.

• Catalytic Materials • Previous Articles

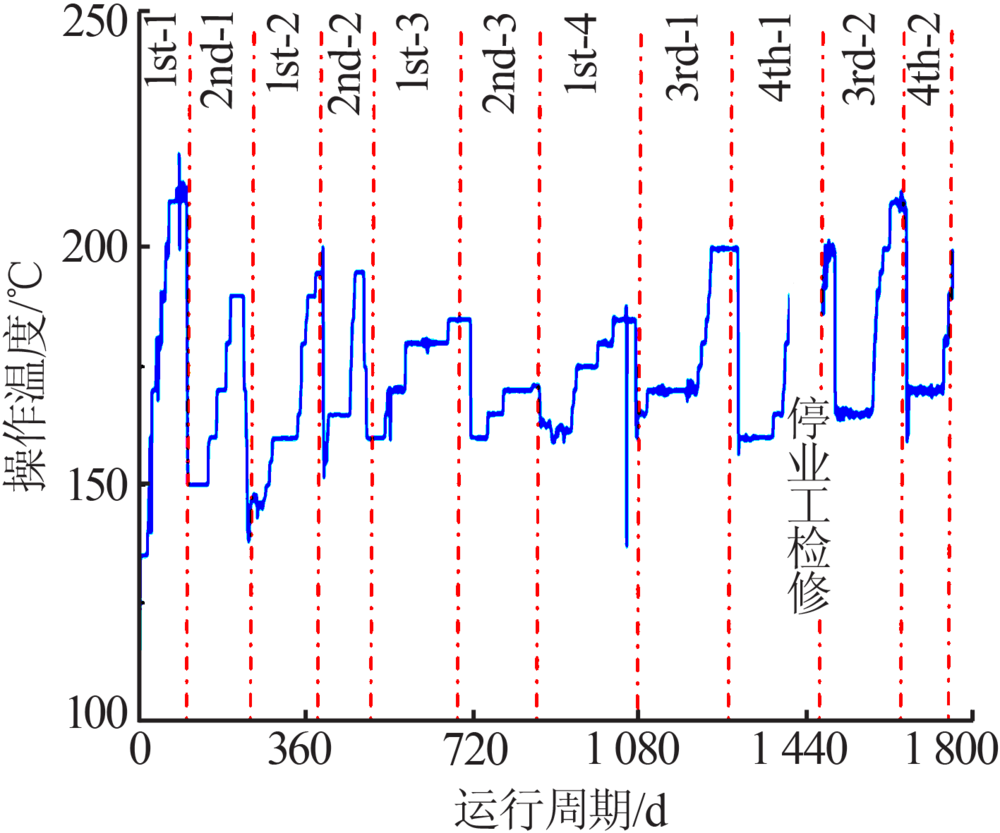

Application of TCDTO-1 olefin-removal refinement catalyst in domestic-manufactured aromatics units

Wang Yubing

- China Petrochemical Co.,Ltd.,Beijing 100728,China