Inorganic Chemicals Industry ›› 2023, Vol. 55 ›› Issue (12): 12-25.doi: 10.19964/j.issn.1006-4990.2023-0243

• Reviews and Special Topics • Previous Articles Next Articles

Research progress of zero liquid discharge pretreatment process for flue gas desulfurization wastewater from coal-fired power plants

LIU Jingying1,2( ), JIA Yangjie3, YANG Fengling1,2(

), JIA Yangjie3, YANG Fengling1,2( ), REN Lei1,2, LI Pengfei4, WANG Fei5, CHENG Fangqin1,2(

), REN Lei1,2, LI Pengfei4, WANG Fei5, CHENG Fangqin1,2( )

)

- 1. Shanxi University,Taiyuan 030006,China

2. Collaborative Innovation Center of High Value-added Utilization of Coal-related Wastes,State Environmental Protection Key Laboratory of Efficient Utilization Technology of Coal Waste Resources,Shanxi University,Taiyuan 030006,China

3. Shanxi Rui En Ze Technology Co.,Ltd.,Taiyuan 030006,China

4. Shanxi Dadi Haike Environmental Protection Technology Co.,Ltd.,Yangquan County 045000,China

5. Shanxi International Energy Yuguang Coal Power Co.,Ltd.,Yangquan County 045000,China

-

Received:2023-04-26Online:2023-12-10Published:2023-12-14 -

Contact:YANG Fengling, CHENG Fangqin E-mail:13294937768@163.com;yangfl@sxu.edu.cn;cfangqin@sxu.edu.cn

CLC Number:

Cite this article

LIU Jingying, JIA Yangjie, YANG Fengling, REN Lei, LI Pengfei, WANG Fei, CHENG Fangqin. Research progress of zero liquid discharge pretreatment process for flue gas desulfurization wastewater from coal-fired power plants[J]. Inorganic Chemicals Industry, 2023, 55(12): 12-25.

share this article

Table 1

Analysis of process routes and problems of zero liquid discharge of flue gas desulfurization wastewater at domestic and foreign"

公司 名称 | 机组/ MW | 设计进 水量/ (m3·h-1) | 总投资 费用/ 万元 | 工艺路线 | 工艺分析 | 存在问题 |

|---|---|---|---|---|---|---|

| 威尔雅公司[ | 336 | 离子交换/化学软化预处理+(晶种式)降膜蒸发器+MED | 产水中的高质量蒸馏液可回用于电厂,循环水最大TDS低于2×10-5 mg/L | 化学软化除硬,后续蒸发需加入晶种法 | ||

| 澳大利亚能源资源公司[ | 110 | 软化+MVR+结晶 | 出水TDS小于20 mg/L,水质好 | 进水水量大 | ||

| ENEL电厂[ | 70、35、15、 35、12 | 中和-混凝-沉淀和软化+晶种式竖管降膜蒸发器浓缩+MED | 操作稳定,蒸发传热效率高;处理效果良好 | 软化不彻底,后续蒸发需加入晶种法 | ||

| 国电汉川电厂[ | 2×1 000 | 36 | 8 600 | 双碱法+集成管式超滤膜 (TUF)+NF+特殊流道卷式反渗透膜(SCRO)+DTRO+MVR | 出水水质好,淡水回收率达93.4%;预处理后水中钙镁离子质量浓度可降到2 mg/L以下;整个系统用水量减少28万t/a,固体废物排放量减少近 7 000 t/a;NaCl纯度高于98.60% | 流程长,设备复杂,占地面积大;预处理加药量大,污泥产生量大,软化成本高;膜浓缩部件对水质波动的适应性差,TUF污堵率高;运行费用较高 |

| 华电包头电厂[ | 2×600 | 120 | 12 900 | 预处理+NF+RO+DTRO+MVR | 淡水回收率为50%~55%;可实现Na2SO4和NaCl分别回收;电耗为60 kW·h/t,吨水造价为108万元,运行成本低 | 进水量大;预处理加药量大,软化成本高;RO膜易污染、浓差极化、结垢 |

| 三水恒益电厂[ | 2×600 | 20 | 6 000 | 常规预处理+两级卧式喷淋MVC+两级卧式MED+卧式圆盘结晶 | 能耗较低,蒸汽消耗为50~60 kg/t,电耗为20~25 kW·h/t,吨水造价为 300万元 | 水质未经软化处理,结垢严重;结晶盐含有重金属无法高效利用,处理成本高 |

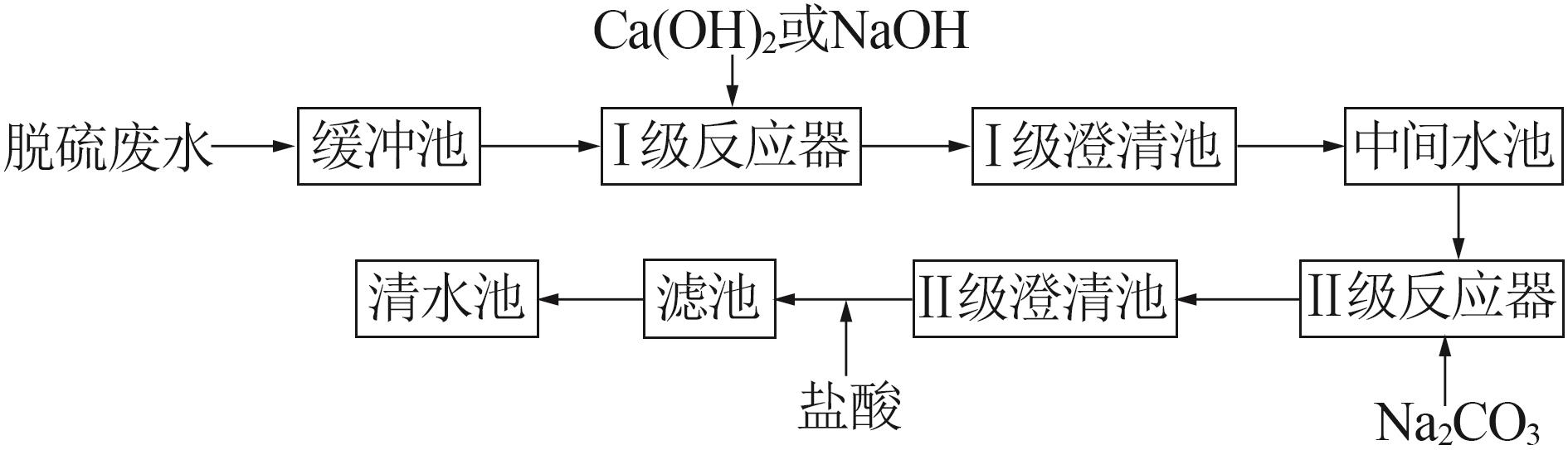

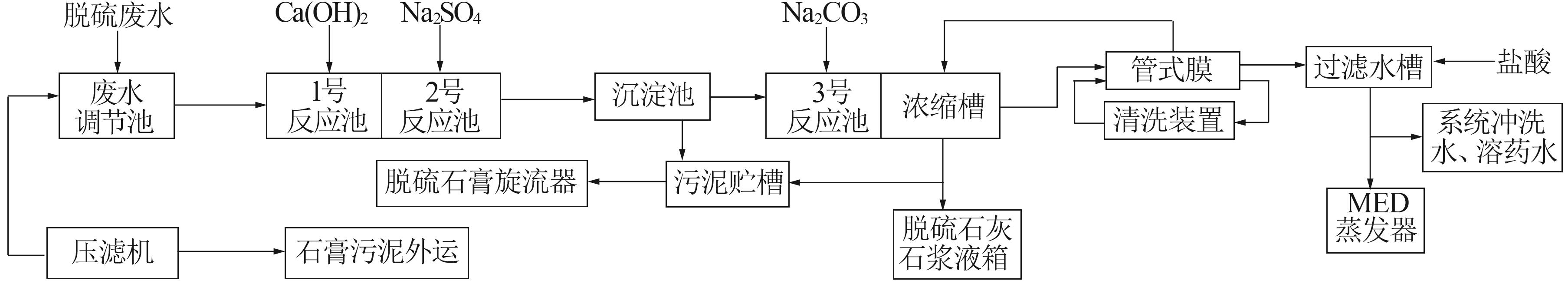

| 深能河源电厂[ | 2×600 | 22 | 9 750 | 两级反应器+两级澄清器+四效立管强制循环蒸发结晶 | 流程适中,水质波动适应性较强;固体盐干燥后达工业二级盐标准,NaCl纯度达95%;蒸汽消耗为280 kg/t,电耗为30 kW·h/t,吨水造价为443万元 | 预处理加药量大,污泥产生量大,软化成本高;MED设备蒸汽消耗较大;投资成本高,系统运行费用高 |

| 华能长兴电厂[ | 2×600 | 22 | 8 000 | 预处理(澄清+过滤+离子交换)+RO+MBC+TVC蒸发结晶 | 系统可实现全自动运行和维护;淡水回收率为80%以上,可回用于锅炉补给水;脱盐率可达97%以上;蒸汽消耗为203 kg/t,电耗为10.4 kW·h/t,吨水造价为364万元 | 流程长;预处理加药量大,污泥产生量大;RO膜易污染、浓差极化、结垢,MBC对水质波动适应性较差;TVC蒸汽耗量较大,产品为杂盐,回收利用困难,运行费用较高 |

| 焦作万方电厂方正汇总行[ | 2×350 | 20 | 3 500 | 双碱(NaOH+Na2CO3)双膜 [微滤(MF)和RO]法预处理 减量+高温烟气旁路蒸发系统 | 淡水回收率达80%;重金属和氯含量符合标准,不影响粉煤灰综合利用;吨水运行费用为25万元 | 流程复杂;可蒸发废水量较低,锅炉效率小幅下降,成本增加 |

Table 2

Comparative analysis of different pretreatment processes"

| 项目 | 运行 成本 | 药剂消耗 | 软化效果 | 工艺流程 | 适用范围 |

|---|---|---|---|---|---|

| 双碱法 | 高 | 种类多、消耗量较大 | 钙镁等硬度离子完全软化、SO42-部分去除、悬浮物和浊度降低 | 较简单 | 水量中等、硬度高、出水水质要求高的燃煤电厂 |

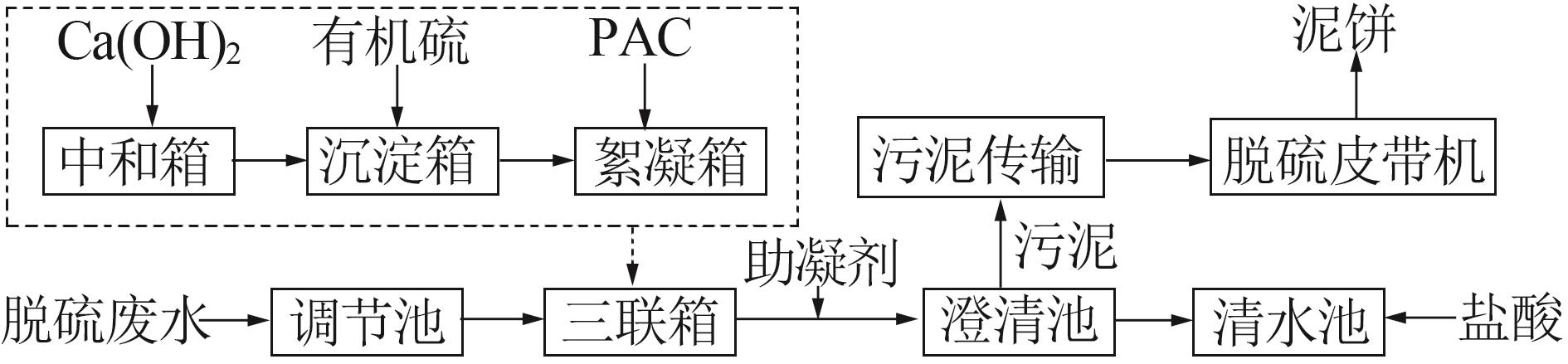

| 三联箱 | 较低 | 种类多、消耗量大 | 钙镁等硬度离子、悬浮物和浊度较高 | 简单 | 水量小、硬度低、出水水质要求低的燃煤电厂 |

| 二氧化碳捕集软化工艺 | 低 | 种类少、消耗量小 | Ca2+、Mg2+、悬浮物去除效果好 | 较复杂 | 水量大、烟道气充足、出水水质要求较高的燃煤电厂 |

| 石灰-铝沉淀法 | 较高 | 种类多、消耗量大 | 钙镁等硬度离子完全软化、SO42-完全去除、悬浮物和浊度极低、沉淀实现分级高效利用 | 复杂 | 出水水质要求高、用地充裕、高浓度SO42-废水的燃煤电厂 |

Table 3

Composition of black filter slag by pressure filtration in pretreatment process"

| w(CaO)/% | w(SiO2)/% | w(Fe2O3)/% | w(Al2O3)/% | w(S)/% | w(Cl)/% | w(K)/% | w(TiO2)/% | w(MnO)/% | w(Zn)/% |

|---|---|---|---|---|---|---|---|---|---|

| 31.55 | 18.95 | 15.58 | 13.97 | 12.31 | 2.05 | 2.71 | 0.99 | 0.95 | 0.14 |

| w(Sc)/10-6 | w(Ni)/10-6 | w(Co)/10-6 | w(V)/10-6 | w(Cu)/10-6 | w(As)/10-6 | w(Pb)/10-6 | w(Cd)/10-6 | w(Cr)/10-6 | w(P)/10-6 |

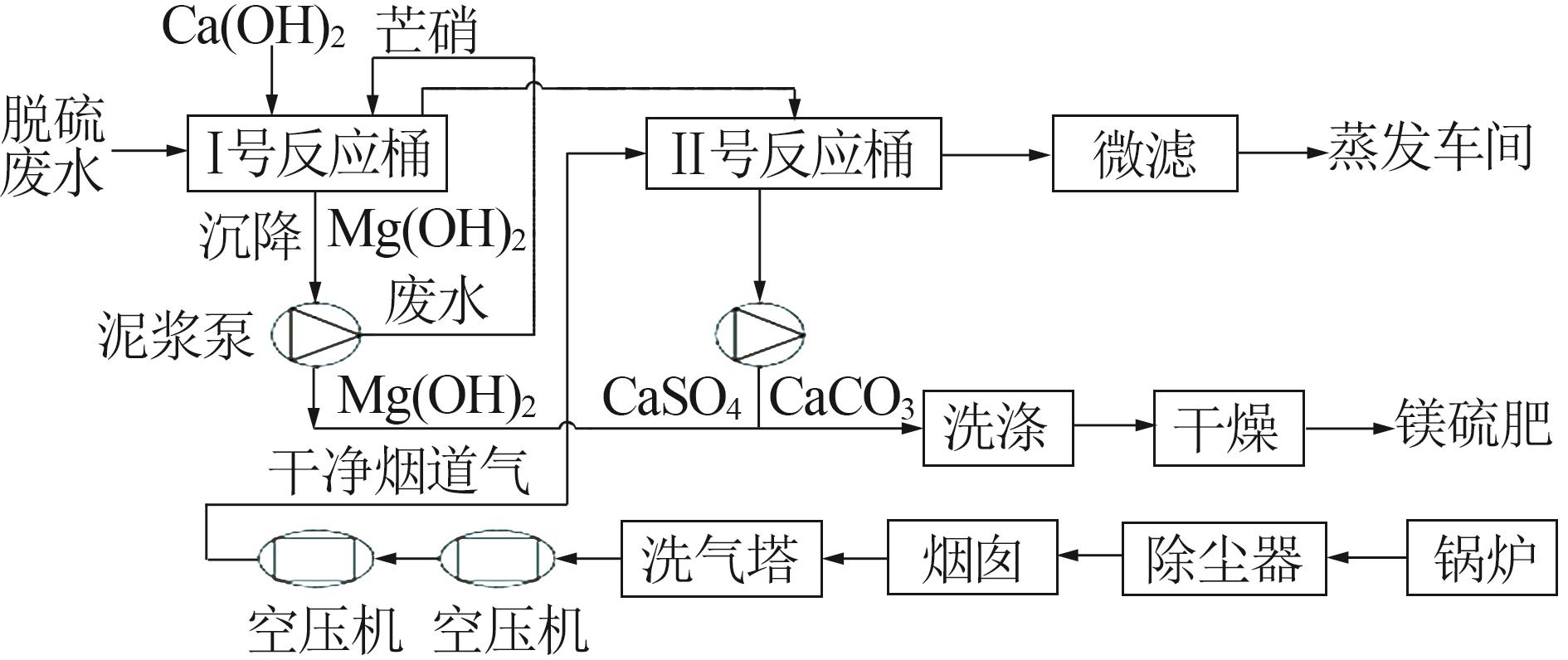

| 614.10 | 595.50 | 579.20 | 176.40 | 84.33 | 69.93 | 26.45 | 29.98 | — | 678.10 |

Table 4

Composition of white filter slag by pressure filtration in secondary clarifier"

| w(CaO)/% | w(S)/% | w(Al2O3)/% | w(Cl)/% | w(Fe2O3)/% | w(SiO2)/% | w(Sc)/% | w(Ni)/% | w(MnO)/% | |

|---|---|---|---|---|---|---|---|---|---|

| 72.96 | 14.54 | 7.90 | 2.01 | 0.75 | 0.59 | 0.34 | 0.19 | 0.17 | |

| w(K)/10-6 | w(TiO2)/10-6 | w(Zn)/10-6 | w(Co)/10-6 | w(Cd)/10-6 | w(Cu)/10-6 | w(V)/10-6 | w(As)/10-6 | w(Cr)/10-6 | w(Pb)/10-6 |

| 820.40 | 533.10 | 179.10 | 131.70 | 43.36 | 42.92 | 23.81 | 15.57 | — | 19.45 |

| 1 | 水利部水资源管理司. 2021年度《中国水资源公报》发布[J]. 水资源开发与管理, 2022, 8(7):85. |

| 2 | 王晓磊, 陈贵锋, 李文博, 等. 双碳背景下煤炭清洁高效利用方向构建[J]. 煤质技术, 2021, 36(6):1-5. |

| WANG Xiaolei, CHEN Guifeng, LI Wenbo, et al. Construction of clean and efficient utilization direction of coal under the background of double carbon[J]. Coal Quality Technology, 2021, 36(6):1-5. | |

| 3 | 国务院. 国务院关于印发水污染防治行动计划的通知[EB/OL].[ 2015-04-16][ 2023-04-26].http:∥www.gov.cn/zhengce/content/2015-04/16/ content_9613.htm. |

| 4 | 唐章程, 黄廷林, 胡瑞柱, 等. 诱导结晶法软化热电厂高永久性硬度水实验研究[J]. 水处理技术, 2019, 45(1):28-32,41. |

| TANG Zhangcheng, HUANG Tinglin, HU Ruizhu, et al. Experimental study on softening the high permanent hardness wastewater from thermal power plant by induced crystallization process[J]. Technology of Water Treatment, 2019, 45(1):28-32,41. | |

| 5 | 何文丽, 何灿, 赵永志, 等. 燃煤电厂脱硫废水零排放技术及工程应用[J]. 给水排水, 2020, 56(4):114-118. |

| HE Wenli, HE Can, ZHAO Yongzhi, et al. Zero-liquid discharge treatment technology of desulfurization wastewater from coal-fired plants and its engineering application[J]. Water & Wastewater Engineering, 2020, 56(4):114-118. | |

| 6 |

TONG Tiezheng, ELIMELECH M. The global rise of zero liquid discharge for wastewater management:Drivers,technologies,and future directions[J]. Environmental Science & Technology, 2016, 50(13):6846-6855.

doi: 10.1021/acs.est.6b01000 |

| 7 | 刘艇安, 许勇毅, 郭磊, 等. 火电厂湿法脱硫废水零排技术研究进展[J]. 应用化工, 2021, 50(8):2313-2316. |

| LIU Tingan, XU Yongyi, GUO Lei, et al. Research progress on non-discharge technology of desulfurization wastewater from coal-fired power plants[J]. Applied Chemical Industry, 2021, 50(8):2313-2316. | |

| 8 |

段威, 姚宣, 王冬生. 燃煤电厂脱硫废水零排放技术对比及经济性分析[J]. 工业水处理, 2021, 41(3):129-132,136.

doi: 10.11894/iwt.2020-0393 |

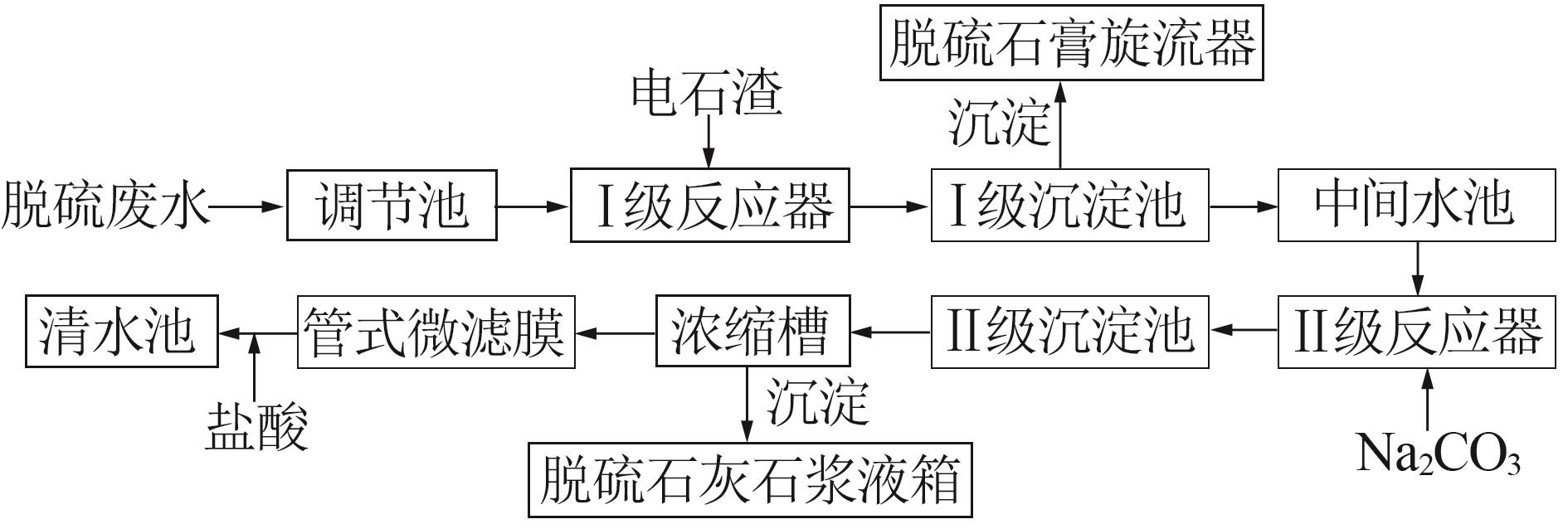

|

DUAN Wei, YAO Xuan, WANG Dongsheng. Technical comparison and economic analysis of desulfurization wastewater zero discharge from coal-fired power plant[J]. Industrial Water Treatment, 2021, 41(3):129-132,136.

doi: 10.11894/iwt.2020-0393 |

|

| 9 | 胡石, 丁绍峰, 樊兆世. 燃煤电厂脱硫废水零排放工艺研究[J]. 洁净煤技术, 2015, 21(2):129-133. |

| HU Shi, DING Shaofeng, FAN Zhaoshi. Zero release technology of desulfurization waste water in coal-fired power plant[J]. Clean Coal Technology, 2015, 21(2):129-133. | |

| 10 | 马双忱, 温佳琪, 万忠诚, 等. 中国燃煤电厂脱硫废水处理技术研究进展及标准修订建议[J]. 洁净煤技术, 2017, 23(4):18-28,35. |

| MA Shuangchen, WEN Jiaqi, WAN Zhongcheng, et al. Treatment progress and standard modification suggestion for FGD wastewater from coal-fire power plants in China[J]. Clean Coal Technology, 2017, 23(4):18-28,35. | |

| 11 | 王正飞. 火力发电厂全厂废水零排放改造方案优化研究:以天津某电厂为例[D]. 济南: 山东建筑大学, 2021. |

| WANG Zhengfei. Study on the optimization of zero discharge of wastewater in Tianjin XXX thermal power plant[D]. Jinan: Shandong Jianzhu University, 2021. | |

| 12 | 杨冬, 杜欣, 王冰. 燃煤电厂脱硫废水零排放技术对比研究[J]. 东北电力大学学报, 2021, 41(4):52-59. |

| YANG Dong, DU Xin, WANG Bing. Comparative study on zero discharge technology of desulfurization wastewater from coal-fired power plant[J]. Journal of Northeast Electric Power University, 2021, 41(4):52-59. | |

| 13 | 王吻, 齐立强, 李晶欣, 等. 脱硫废水中不同类型污染物零排放技术的研究与应用[J]. 应用化工, 2022, 51(7):2126-2133. |

| WANG Wen, QI Liqiang, LI Jingxin, et al. Research and application of zero discharge technology of different pollutants in desulfurization wastewater[J]. Applied Chemical Industry, 2022, 51(7):2126-2133. | |

| 14 |

尹力, 岳春妹, 费剑影. 燃气电厂废水零排放工程应用与研究[J]. 工业水处理, 2022, 42(6):193-197.

doi: 10.19965/j.cnki.iwt.2021-0896 |

|

YIN Li, YUE Chunmei, FEI Jianying. Research and application of wastewater zero discharge process in gas power plant[J]. Industrial Water Treatment, 2022, 42(6):193-197.

doi: 10.19965/j.cnki.iwt.2021-0896 |

|

| 15 | 王水新, 王国庆. 燃煤电厂脱硫废水零排放工艺进展[J]. 节能与环保, 2020(7):70-71. |

| WANG Shuixin, WANG Guoqing. Progress in zero discharge process of desulfurization wastewater from coal fired power plant[J]. Energy Conservation & Environmental Protection, 2020(7):70-71. | |

| 16 | 张江涛, 曹红梅, 李海燕, 等. 火电厂脱硫废水浓缩技术研究进展[J]. 水处理技术, 2022, 48(10):26-32. |

| ZHANG Jiangtao, CAO Hongmei, LI Haiyan, et al. Research progress of desulfurization wastewater concentration technology in thermal power plant[J]. Technology of Water Treatment, 2022, 48(10):26-32. | |

| 17 |

胡大龙, 余耀宏, 于胜利, 等. 燃煤电厂脱硫废水处理技术现状与发展[J]. 工业水处理, 2023, 43(2):43-52.

doi: 10.19965/j.cnki.iwt.2021-1324 |

|

HU Dalong, YU Yaohong, YU Shengli, et al. Present situation and development of treatment technology for desulfurization wastewater in coal-fired power station[J]. Industrial Water Treatment, 2023, 43(2):43-52.

doi: 10.19965/j.cnki.iwt.2021-1324 |

|

| 18 | 刘俊. 脱硫废水零排放软化浓缩工艺应用实例[J]. 工业用水与废水, 2021, 52(6):52-56. |

| LIU Jun. Application example of softening and concentration process of zero discharge of desulfurization wastewater[J]. Industrial Water & Wastewater, 2021, 52(6):52-56. | |

| 19 | 郭宗林, 何志军, 吕超, 等. 多通道电渗析应用于高盐废水处理的试验研究[J]. 水利技术监督, 2022, 30(7):177-179. |

| GUO Zonglin, HE Zhijun, Chao LÜ, et al. Experimental study on the application of multi-channel electrodialysis in the treatment of high-salt wastewater[J]. Technical Supervision in Water Resources, 2022, 30(7):177-179. | |

| 20 |

LI Bing, KE Xiaoxue, YUAN Zhihua, et al. High performance electrospun thin-film composite forward osmosis membrane by tailoring polyamide active layer with polydopamine interlayer for desulfulrization wastewater desalination[J]. Desalination, 2022, 534:115781.

doi: 10.1016/j.desal.2022.115781 |

| 21 |

LI Bing, KE Xiaoxue, ZHONG Lubin, et al. Super-hydrophilic nanofiber substrate supported forward osmosis membrane with less polyamide layer defects by polydopamine-graphene oxide modification for high salinity desulfurization wastewater desalination[J]. Journal of Membrane Science, 2022, 659:120767.

doi: 10.1016/j.memsci.2022.120767 |

| 22 | 高永钢, 史志伟. 膜蒸馏在火电厂脱硫废水零排工艺中的技术经济分析[J]. 华电技术, 2020, 42(3):25-30. |

| GAO Yonggang, SHI Zhiwei. Techno-economic analysis on membrane distillation in desulfurization wastewater ZLD process of coal-fired power plants[J]. Huadian Technology, 2020, 42(3):25-30. | |

| 23 |

HAN Xiaoqu, ZHANG Dan, YAN Junjie, et al. Process development of flue gas desulphurization wastewater treatment in coal-fired power plants towards zero liquid discharge:Energetic,economic and environmental analyses[J]. Journal of Cleaner Production, 2020, 261:121144.

doi: 10.1016/j.jclepro.2020.121144 |

| 24 | 赵舒然, 韩小渠, 张丹, 等. 燃煤电厂脱硫废水热法零排放技术热成本分析[J]. 中国电力, 2020, 53(7):184-188,196. |

| ZHAO Shuran, HAN Xiaoqu, ZHANG Dan, et al. Thermal cost analysis on thermal zero discharge technology for flue gas desulfurization(FGD) wastewater of coal-fired units[J]. Electric Power, 2020, 53(7):184-188,196. | |

| 25 | 万勇刚, 徐峰, 田旭峰, 等. 国电汉川发电有限公司脱硫废水蒸发结晶项目工艺解析[J]. 华电技术, 2017, 39(10):74-76,80. |

| WAN Yonggang, XU Feng, TIAN Xufeng, et al. Guodian hanchuan power generation company limited desulfurization waste water evaporative crystallization project process analysis[J]. Huadian Technology, 2017, 39(10):74-76,80. | |

| 26 | 韩倩倩, 游晓宏, 朱一鸣, 等. 膜浓缩+蒸发塘处理工艺在燃气电厂废水零排放中的应用[J]. 现代化工, 2022, 42(8):215-219. |

| HAN Qianqian, YOU Xiaohong, ZHU Yiming, et al. Application of membrane concentration+evaporation pond process in zero discharge treatment of wastewater from gas-fired power plant[J]. Modern Chemical Industry, 2022, 42(8):215-219. | |

| 27 | 杨跃伞, 苑志华, 张净瑞, 等. 燃煤电厂脱硫废水零排放技术研究进展[J]. 水处理技术, 2017, 43(6):29-33. |

| YANG Yuesan, YUAN Zhihua, ZHANG Jingrui, et al. Research progress of technologies for zero-discharge of desulfurization wastewater from coal-fired power plants[J]. Technology of Water Treatment, 2017, 43(6):29-33. | |

| 28 | 周川, 吴其荣, 喻江涛, 等. 2×350 MW燃煤发电机组主烟道脱硫废水蒸发数值模拟[J]. 环境工程, 2020, 38(5):96-101. |

| ZHOU Chuan, WU Qirong, YU Jiangtao, et al. Numerical simulation for fgd wastewater evaporation in the flue duct of a 2×350 MW coal-fired unit[J]. Environmental Engineering, 2020, 38(5):96-101. | |

| 29 | 张净瑞, 梁海山, 郑煜铭, 等. 基于旁路烟道蒸发的脱硫废水零排放技术在火电厂的应用[J]. 环境工程, 2017, 35(10):5-9. |

| ZHANG Jingrui, LIANG Haishan, ZHENG Yuming, et al. Application of zero liquid discharge system of the desulfurization wastewater based on bypass flue evaporation system in thermal power plants[J]. Environmental Engineering, 2017, 35(10):5-9. | |

| 30 |

FU Jiangtao, HU Ning, YANG Zhongqing, et al. Experimental study on zero liquid discharge(ZLD) of FGD wastewater from a coal-fired power plant by flue gas exhausted heat[J]. Journal of Water Process Engineering, 2018, 26:100-107.

doi: 10.1016/j.jwpe.2018.10.005 |

| 31 |

马双忱, 陈嘉宁, 万忠诚, 等. 高盐脱硫废水水泥化固定技术的研究现状与发展[J]. 化工进展, 2019, 38(9):4275-4283.

doi: 10.16085/j.issn.1000-6613.2018-2422 |

|

MA Shuangchen, CHEN Jianing, WAN Zhongcheng, et al. Research status and development on solidification for high-salt desulfurization wastewater with cement[J]. Chemical Industry and Engineering Progress, 2019, 38(9):4275-4283.

doi: 10.16085/j.issn.1000-6613.2018-2422 |

|

| 32 | 刘世杰, 邝文斌, 李锋, 等. 燃煤电厂废水综合治理近零排放解决方案探讨[J]. 给水排水, 2021, 57(9):69-75,80. |

| LIU Shijie, KUANG Wenbin, LI Feng, et al. Discussion on zero emission solution for comprehensive treatment of wastewater from a coal-fired power plant[J]. Water & Wastewater Engineering, 2021, 57(9):69-75,80. | |

| 33 | 杨铭. 燃煤电厂脱硫废水零排放中试试验研究[D]. 北京: 北京化工大学, 2019. |

| YANG Ming. Pilot test study on zero discharge of desulfurization wastewater from coal-fired power plants[D]. Beijing: Beijing University of Chemical Technology, 2019.. | |

| 34 | 刘果, 李智彪, 徐勤云. 脱硫废水零排放一体化处理工艺研究[J]. 中国资源综合利用, 2017, 35(2):25-27. |

| LIU Guo, LI Zhibiao, XU Qinyun. Study on the integrated process of desulfurization waste water′s zero-draining disposal[J]. China Resources Comprehensive Utilization, 2017, 35(2):25-27. | |

| 35 |

MA Hongpeng, WANG Hualin, TIAN Chengcheng, et al. An optimized design for zero liquid discharge from coal chemical industry:A case study in China[J]. Journal of Cleaner Production, 2021, 319:128572.

doi: 10.1016/j.jclepro.2021.128572 |

| 36 |

CHEN Fayuan, ZHANG Zhong, ZENG Fengmi, et al. Pilot-scale treatment of hypersaline coal chemical wastewater with zero liquid discharge[J]. Desalination, 2021, 518:115303.

doi: 10.1016/j.desal.2021.115303 |

| 37 | 徐志清, 赵焰, 陆梦楠. 燃煤电厂脱硫废水零排放工程案例解析[J]. 电力科技与环保, 2020, 36(2):6-12. |

| XU Zhiqing, ZHAO Yan, LU Mengnan. Engineering case analysis of zero liquid discharge system of desulfurization wastewater in a Power Plant[J]. Electric Power Technology and Environmental Protection, 2020, 36(2):6-12. | |

| 38 | 李飞. 燃煤电厂脱硫废水零排放技术应用与研究进展[J]. 水处理技术, 2020, 46(12):17-24. |

| LI Fei. Application and research progresses of technologies for zero-discharge of desulfurization wastewater from coal-fired power plants[J]. Technology of Water Treatment, 2020, 46(12):17-24. | |

| 39 |

孙振宇, 沈明忠. 燃煤电厂脱硫废水零排放工程案例研究[J]. 工业水处理, 2018, 38(10):102-105.

doi: 10.11894/1005-829x.2018.38(10).102 |

|

SUN Zhenyu, SHEN Mingzhong. Case study on zero discharge engineering of desulphurization wastewater in coal-fired power plants[J]. Industrial Water Treatment, 2018, 38(10):102-105.

doi: 10.11894/1005-829x.2018.38(10).102 |

|

| 40 | 刘秋生. 烟气脱硫废水“零排放”技术应用[J]. 热力发电, 2014, 43(12):114-117. |

| LIU Qiusheng. Application and comparison of′zero discharge′ technology for desulfurization waste water[J]. Thermal Power Generation, 2014, 43(12):114-117. | |

| 41 | 窦晓春, 张婷婷. 对华能长兴电厂废水零排放调研的几点思考[J]. 电力科技与环保, 2017, 33(6):31-33. |

| DOU Xiaochun, ZHANG Tingting. Some thoughts on the zero emission research of huaneng changxing power plant[J]. Electric Power Technology and Environmental Protection, 2017, 33(6):31-33. | |

| 42 | 来勇. 化学沉淀—絮凝法处理双碱法烟气脱硫废水[D]. 杭州: 浙江大学, 2005. |

| LAI Yong. Wastewater treatment for dual-alkali flue gas desulfurization by chemical precipitation and flocculation[D]. Hangzhou: Zhejiang University, 2005. | |

| 43 | 赵硕. 脱硫废水预处理及其溶液结构的研究[D]. 天津: 河北工业大学, 2020. |

| ZHAO Shuo. Pretreatment of desulfurization wastewater and its solution structure[D]. Tianjin: Hebei University of Technology, 2020. | |

| 44 |

CHENG Qingfeng, WU Yalan, HUANG Yang, et al. An integrated process of calcium hydroxide precipitation and air stripping for pretreatment of flue gas desulfurization wastewater towards zero liquid discharge[J]. Journal of Cleaner Production, 2021, 314:128077.

doi: 10.1016/j.jclepro.2021.128077 |

| 45 | 张娟, 刘平元, 吉顺健, 等. 燃煤电厂脱硫废水零排放预处理工艺选择与实践[J]. 动力工程学报, 2019, 39(10):840-846. |

| ZHANG Juan, LIU Pingyuan, JI Shunjian, et al. Selection and practice of pretreatment process for zero liquid discharge of desulfurization wastewater from coal-fired power plant[J]. Journal of Chinese Society of Power Engineering, 2019, 39(10):840-846. | |

| 46 | 王海棠, 钟振成, 王靖宇, 等. 高镁型脱硫废水零排放处理技术研究[J]. 应用化工, 2022, 51(9):2762-2766,2773. |

| WANG Haitang, ZHONG Zhencheng, WANG Jingyu, et al. Study on zero discharge treatment technology of desulfurization wastewater with high magnesium ions[J]. Applied Chemical Industry, 2022, 51(9):2762-2766,2773. | |

| 47 | 连坤宙, 胡特立, 王永前, 等. 燃煤电厂脱硫废水预处理装置设计与中试研究[J]. 中国电力, 2018, 51(6):166-171. |

| LIAN Kunzhou, HU Teli, WANG Yongqian, et al. Pretreatment device design and pilot application of desulfurization wastewater in coal-fired power plants[J]. Electric Power, 2018, 51(6):166-171. | |

| 48 | 刘亚鹏, 王金磊, 陈景硕, 等. 火电厂脱硫废水预处理工艺优化及管式微滤膜实验研究[J]. 中国电力, 2016, 49(2):153-158. |

| LIU Yapeng, WANG Jinlei, CHEN Jingshuo, et al. Optimization of FGD wastewater pretreatment technique for thermal power pl-ant and test studies on tubular crossflow microfiltration process[J]. Electric Power, 2016, 49(2):153-158. | |

| 49 | 庞冬, 贾尔恒·阿哈提, 何秉宇, 等. 某火电厂湿法脱硫废水水质分析及处理工艺优化[J]. 水处理技术, 2018, 44(8):89-93. |

| PANG Dong, JIAERHENG Ahati, HE Bingyu, et al. Water quality analysis and treatment process optimization of wet flue gas desulphurization wastewater in a thermal power plant[J]. Technology of Water Treatment, 2018, 44(8):89-93. | |

| 50 | 汪岚, 蔡井刚, 胡治平. 石灰-芒硝-烟道气法软化脱硫废水的可行性分析[J]. 浙江电力, 2016, 35(2):48-50,67. |

| WANG Lan, CAI Jinggang, HU Zhiping. Feasibility analysis of desulphurization wastewater softening through lime-mirabilite-flue gas method[J]. Zhejiang Electric Power, 2016, 35(2):48-50,67. | |

| 51 | 吴志勇. 废水蒸发浓缩工艺在脱硫废水处理中的应用[J]. 华电技术, 2012, 34(11):63-66,81. |

| WU Zhiyong. Application of wastewater evaporation concentration technology in desulphurization wastewater treatment[J]. Hua-dian Technology, 2012, 34(11):63-66,81. | |

| 52 |

GUO Jiaming, ZHOU Zhen, SUN Dongqi, et al. Recovering double-metal hydroxides precipitate from desalination process of saline wastewater as conditioner for excess sludge dewatering[J]. Chemical Engineering Journal, 2022, 434:134787.

doi: 10.1016/j.cej.2022.134787 |

| 53 |

GUO Jiaming, ZHOU Zhen, MING Qiang, et al. Recovering chemical sludge from the zero liquid discharge system of flue gas desulfurization wastewater as flame retardants by a stepwise precipitation process[J]. Journal of Hazardous Materials, 2021, 417:126054.

doi: 10.1016/j.jhazmat.2021.126054 |

| 54 |

王玉东, 赵丹, 董延茂, 等. 钙矾石沉淀法去除镁剂脱硫废水中硫酸根离子研究[J]. 工业水处理, 2015, 35(6):54-57.

doi: 10.11894/1005-829x.2015.35(6).014 |

|

WANG Yudong, ZHAO Dan, DONG Yanmao, et al. Research on the removal of sulfate from magnesium flue gas desulfurization wastewater by ettringite precipitation method[J]. Industrial Water Treatment, 2015, 35(6):54-57.

doi: 10.11894/1005-829x.2015.35(6).014 |

|

| 55 |

徐敏, 杜洪宇, 窦微笑, 等. 钙矾石法去除脱硫废水硫酸根沉淀物沉降特性研究[J]. 工业水处理, 2022, 42(3):123-130.

doi: 10.19965/j.cnki.iwt.2021-0655 |

|

XU Min, DU Hongyu, DOU Weixiao, et al. Settleability of ettringite precipitate for sulfate removal from flue gas desulfurization wastewater[J]. Industrial Water Treatment, 2022, 42(3):123- 130.

doi: 10.19965/j.cnki.iwt.2021-0655 |

|

| 56 | 徐敏, 杜洪宇, 郭家明, 等. 面向物质资源化的燃煤电厂脱硫废水零排放工艺研究[J]. 环境工程, 2022, 40(10):169-175. |

| XU Min, DU Hongyu, GUO Jiaming, et al. A pilot-scale experiment for zero liquid discharge and resource recovery of flue gas desulfurization wastewater in coal-fired power plants[J]. Environmental Engineering, 2022, 40(10):169-175. | |

| 57 |

XIN Yi, ZHOU Zhen, MING Qiang, et al. A two-stage desalination process for zero liquid discharge of flue gas desulfurization wastewater by chloride precipitation[J]. Journal of Hazardous Materials, 2020, 397:122744.

doi: 10.1016/j.jhazmat.2020.122744 |

| 58 |

SEMBLANTE G U, LEE J Z, LEE L Y, et al. Brine pre-treatment technologies for zero liquid discharge systems[J]. Desalination, 2018, 441:96-111.

doi: 10.1016/j.desal.2018.04.006 |

| 59 | 马双忱, 于伟静, 贾绍广, 等. 燃煤电厂脱硫废水处理技术研究与应用进展[J]. 化工进展, 2016, 35(1):255-262. |

| MA Shuangchen, YU Weijing, JIA Shaoguang, et al. Research and application progresses of flue gas desulfurization(FGD) wastewater treatment technologies in coal-fired plants[J]. Chemical Industry and Engineering Progress, 2016, 35(1):255-262. | |

| 60 | 李岩. 燃煤电厂脱硫废水处理回用的技术研究[D]. 北京: 华北电力大学, 2017. |

| LI Yan. Research on treatment and reuse of desulfurization wastewater in coal-fired power plant[D]. Beijing: North China Electric Power University, 2017. | |

| 61 | 赵国钦. 燃煤电厂废水零排放技术路线适应性分析及研究[J]. 环保科技, 2020, 26(3):16-21,26. |

| ZHAO Guoqin. Analysis and study of adaptation of technical ro-utes for zero wastewater emission from coal-fired power plants[J]. Environmental Protection and Technology, 2020, 26(3):16-21,26. | |

| 62 | 鲁佳. 燃煤锅炉湿法烟气脱硫废水“零排放”新工艺研究[D]. 天津: 天津大学, 2016. |

| LU Jia. The study on new "zero liquid discharge"process for treating wet FGD wastewater from coal-fired boilers[D]. Tianjin: Tianjin University, 2016. | |

| 63 | 刘亚争. 燃煤电厂高镁脱硫废水中钙镁回收工艺研究[D]. 北京: 华北电力大学, 2020. |

| LIU Yazheng. Research on recovery process of calcium and magnesium in high magnesium desulfurization wastewater from coal-fired power plant[D]. Beijing: North China Electric Power University, 2020. | |

| 64 | 刘彦彦, 陈峻峰, 唐美珍, 等. 典型燃煤火力发电厂脱硫废水预处理优化[J]. 曲阜师范大学学报(自然科学版), 2019, 45(2):73-77. |

| LIU Yanyan, CHEN Junfeng, TANG Meizhen, et al. Optimization for desulfurization wastewater pretreatment in a typical coal-fired thermal power plant[J]. Journal of Qufu Normal University(Na-Science) tural, 2019, 45(2):73-77. | |

| 65 | 孙明坤. 基于脱硫废水零排放的软化技术实验研究[D]. 北京: 华北电力大学, 2020. |

| SUN Mingkun. Experimental study on softening technology based on zero liquid discharge of wet-FGD wastewater[D]. Beijing: North China Electric Power University, 2020. | |

| 66 | 赵立文, 朱干宇, 李少鹏, 等. 电石渣特性及综合利用研究进展[J]. 洁净煤技术, 2021, 27(3):13-26. |

| ZHAO Liwen, ZHU Ganyu, LI Shaopeng, et al. Research progress on characteristics and comprehensive utilization of calcium carbide slag[J]. Clean Coal Technology, 2021, 27(3):13-26. | |

| 67 | 梁磊. 电石渣-石膏湿法烟气脱硫工艺技术研究[J]. 中国电力, 2016, 49(6):166-169,175. |

| LIANG Lei. Study on carbide slag-gypsum wet flue gas desulfurization process technology[J]. Electric Power, 2016, 49(6):166-169,175. | |

| 68 | 姜正雄. 燃煤电厂电石渣-石膏湿法烟气脱硫试验及应用分析[J]. 锅炉技术, 2019, 50(4):10-14. |

| JIANG Zhengxiong. Experiment and application analysis on carbide slag-gypsum wet method of flue gas desulfurization technology for coal fired power plant[J]. Boiler Technology, 2019, 50(4):10-14. | |

| 69 | 叶旭润. 燃煤电厂脱硫废水“零排放”工艺技术研究[D]. 北京: 北京交通大学, 2019. |

| YE Xurun. Study on “zero emission”technology of desulfurization wastewater from coal-fired power plants[D]. Beijing: Beijing Jiaotong University, 2019. | |

| 70 |

叶旭润, 李进, 黄忠源, 等. 电石渣-碳酸钠法脱硫废水预处理试验研究[J]. 北京交通大学学报, 2019, 43(6):124-130.

doi: 10.11860/j.issn.1673-0291.20180140 |

|

YE Xurun, LI Jin, HUANG Zhongyuan, et al. Experimental study on the pretreatment of desulphurization waste-water by using carbide slag and sodium carbonate[J]. Journal of Beijing Jiaotong University, 2019, 43(6):124-130.

doi: 10.11860/j.issn.1673-0291.20180140 |

| [1] | JIN Suna, LÜ Ruiliang. Research and application progress of wet flue gas desulfurization wastewater treatment technology [J]. Inorganic Chemicals Industry, 2023, 55(4): 27-37. |

| [2] | LI Li,LI Yu,JIN Yan,QIU Jun,YANG Ying,ZHANG Yonghong,XIAO Fang,YU Jianguo. Key technology and application of lithium extraction from produced water in high sulfur and high hardness gas fields [J]. Inorganic Chemicals Industry, 2023, 55(1): 74-80. |

| [3] | GU Qingshan,LIN Xihua,Zhao Shihao,YUAN Yijin. Effect of different pretreatment processes on properties of phosphogypsum [J]. Inorganic Chemicals Industry, 2022, 54(4): 17-23. |

| [4] | Sun Fengjuan,Liu Wanchao,Yan Kun,E Yishuai. Removal of chloride ion from desulfurization wastewater by ion-exchange resin [J]. Inorganic Chemicals Industry, 2019, 51(6): 45-48. |

| [5] | WEN Yan-Bing, ZHANG Qin, GU Chun-Guang, LU Yu-Lian, ZHANG Lan-Xi, HAN Yu. Research progress on pretreatment technology of medium-and low-grade phosphate rock [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(7): 7-. |

| [6] | Zhang Xuejie;Zhang Zhiye;Wang Xinlong. Study on micro-pores of phosphate rock in sulfuric acid pretreatment process [J]. INORGANICCHEMICALSINDUSTRY, 2010, 0(3): 0-0. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|

||