Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (5): 105-110.doi: 10.11962/1006-4990.2020-0285

• Catalytic Materials • Previous Articles

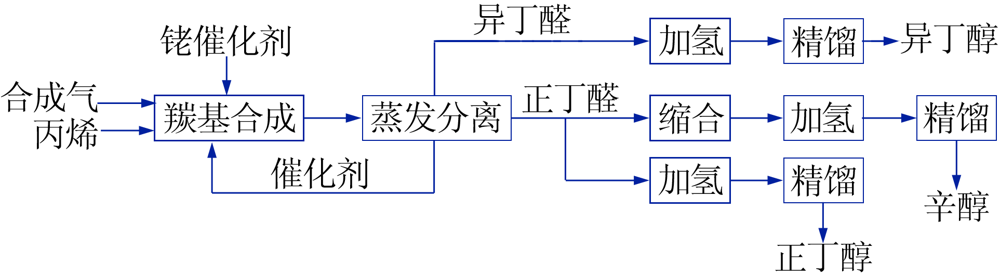

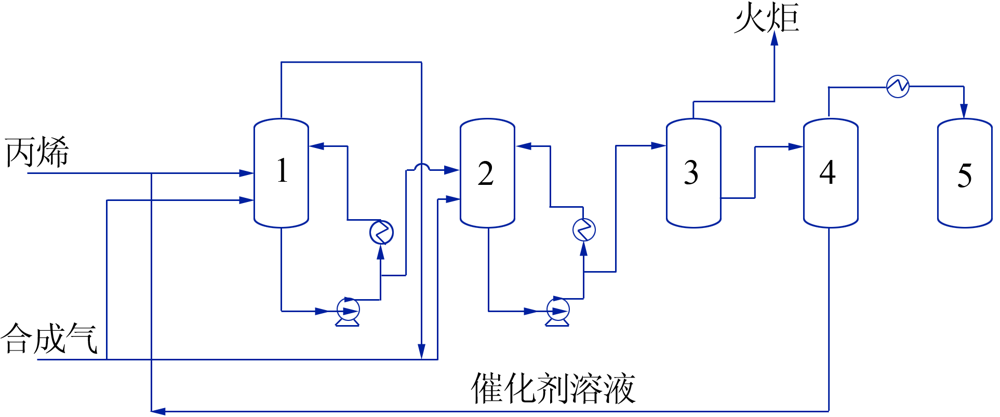

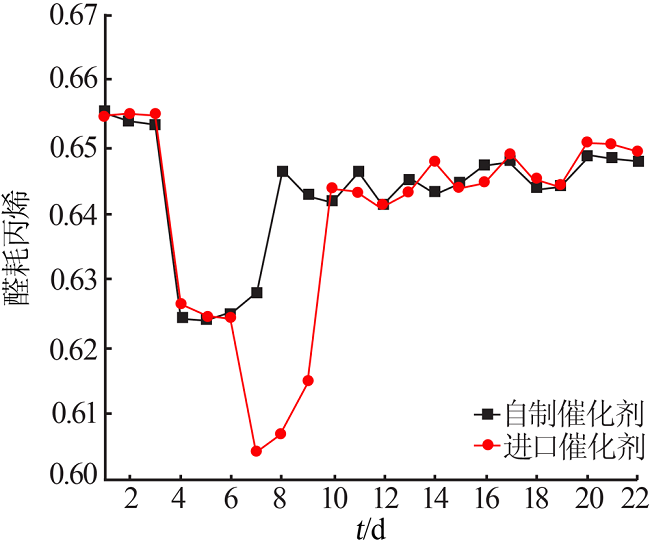

Stndy on preparation and industrial side line experiment of catalyst in synthesis of butyl octanol

Wang Pengfei1,2( ),Jiang Lingyun1,2,Li Chen1,2,Li Jixia1,2,Hao Tingting1,2,Wang Benlei1,2,Zang Jiazhong1,2,Wu Qing3

),Jiang Lingyun1,2,Li Chen1,2,Li Jixia1,2,Hao Tingting1,2,Wang Benlei1,2,Zang Jiazhong1,2,Wu Qing3

- 1. CenerTech Tianjin Chemical Research and Design Institute Co.,Ltd.,Tianjin 300131,China

2. Tianjin Refining and Catalytic Technology Engineering Center

3. China National Offshore Oil Co.,Ltd.