Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (1): 1-6.doi: 10.11962/1006-4990.2020-0213

Research progress of improving gas separation performance of inorganic fillers for mixed matrix membranes

Quan Kaidong1( ),Pan Fusheng1,Chen Zan2,Duan Cuijia2,Yuan Biao2,Yan Shuo2

),Pan Fusheng1,Chen Zan2,Duan Cuijia2,Yuan Biao2,Yan Shuo2

- 1. School of Chemical Engineering and Technology,Tianjin University,Tianjin 300072,China

2. CenerTech Tianjin Chemical Research and Design Institute Co.,Ltd.

-

Received:2020-07-21Online:2021-01-10Published:2021-01-08

CLC Number:

Cite this article

Quan Kaidong,Pan Fusheng,Chen Zan,Duan Cuijia,Yuan Biao,Yan Shuo. Research progress of improving gas separation performance of inorganic fillers for mixed matrix membranes[J]. Inorganic Chemicals Industry, 2021, 53(1): 1-6.

share this article

| [1] | Zhang Y, Zhao W, Fu L, et al. Land use conversion influences soil respiration across a desert-oasis ecoregion in Northwest China,with consideration of cold season CO2 efflux and its significance[J]. Ca-tena, 2020,188:104460. |

| [2] | Zhang S, Shen Y, Wang L, et al. Phase change solvents for post-com-bustion CO2 capture: Principle,advances,and challenges[J]. App-lied Energy, 2019,239:876-897. |

| [3] | Han J, Zhang L, Zhao B, et al. The N-doped activated carbon deriv-ed from sugarcane bagasse for CO2 adsorption[J]. Industrial Cropsand Products, 2019,128:290-297. |

| [4] |

Kim D, Han J. Comprehensive analysis of two catalytic processes to produce formic acid from carbon dioxide[J]. Applied Energy, 2020,264:114711.

doi: 10.1016/j.apenergy.2020.114711 |

| [5] |

Li Z, Yang T, Yuan S, et al. Boudouard reaction driven by thermal plasma for efficient CO2 conversion and energy storage[J]. Journal of Energy Chemistry, 2020,45:128-134.

doi: 10.1016/j.jechem.2019.10.007 |

| [6] |

Mohammad M, Isaifan R J, Weldu Y W, et al. Progress on carbon dioxide capture,storage and utilisation[J]. International Journal of Global Warming, 2020,20(2):124-144.

doi: 10.1504/IJGW.2020.105386 |

| [7] | Hou B S, Zhang Q H, Li Y Y, et al. Influence of corrosion products on the inhibition effect of pyrimidine derivative for the corrosion of carbon steel under supercritical CO2 conditions[J]. Corrosion Sci-ence, 2020,166:108442. |

| [8] | Karaszova M, Zach B, Petrusova Z, et al. Post-combustion carbon ca-pture by membrane separation[J]. Separation and Purification Tech-nology, 2020,238:116448. |

| [9] | Hwang S B, Seo Y T, Park S M, et al. Natural gas treatment system for offshore structure,has carbon dioxide liquefier for liquefying car-bon dioxide heated in carbon dioxide heat exchanger,and carbon dioxide pump for delivering liquefied carbon dioxide to reinjection well:KR,2074084-B1[P]. 2020-02-05. |

| [10] |

Rouzitalab Z, Maklavany D M, Jafarinejad S, et al. Lignocellulose-based adsorbents:A spotlight review of the effective parameters on carbon dioxide capture process[J]. Chemosphere, 2020,246:125756.

doi: 10.1016/j.chemosphere.2019.125756 pmid: 31918088 |

| [11] |

Pang S. Advances in thermochemical conversion of woody biomass to energy,fuels and chemicals[J]. Biotechnology Advances, 2019,37(4):589-597.

doi: 10.1016/j.biotechadv.2018.11.004 pmid: 30447327 |

| [12] | Li X, Sun Y, Feng F, et al. Precious metal extractant comprises ionic liquid,trichloroisocyanuric acid or dichloroisocyanuric acid,and asolvent and anion of the ionic liquid comprises at least one of chloride,bromide,iodide,thiocyanate or dinitrile amine ion:CS,110484746A[P]. 2019-11-22. |

| [13] |

Jiang Z, Chu L, Wu X, et al. Membrane-based separation technolo-gies:from polymeric materials to novel process:an outlook from China[J]. Reviews in Chemical Engineering, 2020,36(1):67-105.

doi: 10.1515/revce-2017-0066 |

| [14] | Park H B, Kamcev J, Robeson L M, et al. Maximizing the right st-uff:The trade-off between membrane permeability and selectivi-ty[J]. Science, 2017,356(6343):28619885. |

| [15] | Tang X, Liu J, Shang H, et al. Gas diffusion and adsorption capaci-ty enhancement via ultrasonic pretreatment for hydrothermal syn-journal of K-KFI zeolite with nano/micro-scale crystals[J]. Micropo-rous and Mesoporous Materials, 2020,297:110036. |

| [16] | Wilson S M W, Kennedy D A, Tezel F H. Adsorbent screening for CO2/CO separation for applications in syngas production[J]. Sepa-ration and Purification Technology, 2020,236:116268. |

| [17] |

Lee D W, Didriksen T, Olsbye U, et al. Shaping of metal-organic framework UiO-66 using alginates:Effect of operation variables[J]. Separation and Purification Technology, 2020,235:116182.

doi: 10.1016/j.seppur.2019.116182 |

| [18] |

Kamble A R, Patel C M, Murthy Z V P. Different 2D materials bas-ed polyetherimide mixed matrix membranes for CO2/N2 separat-ion[J]. Journal of Industrial and Engineering Chemistry, 2020,81:451-463.

doi: 10.1016/j.jiec.2019.09.035 |

| [19] | Favvas E P, Katsaros F K, Papageorgiou S K, et al. A review of the latest development of polyimide based membranes for CO2 separations[J]. Reactive & Functional Polymers, 2017,120:104-130. |

| [20] |

Qian Q, Wu A X, Chi W S, et al. Mixed-matrix membranes formed from imide-functionalized UiO-66-NH2 for improved interfacial compatibility[J]. Acs Applied Materials & Interfaces, 2019,11(34):31257-31269.

doi: 10.1021/acsami.9b07500 pmid: 31362491 |

| [21] |

Rodenas T, Luz I, Prieto G, et al. Metal-organic framework nano-sheets in polymer composite materials for gas separation[J]. Na-ture Materials, 2015,14(1):48-55.

doi: 10.1038/nmat4113 pmid: 25362353 |

| [22] |

Loloei M, Omidkhah M, Moghadassi A, et al. Preparation and cha-racterization of based binary and ternary mixed matrix membranes for CO2 separation[J]. International Journal of Greenhouse Gas Control, 2015,39:225-235.

doi: 10.1016/j.ijggc.2015.04.016 |

| [23] |

Kim S Y, Cho Y, Kang S W. Correlation between functional group and formation of nanoparticles in PEBAX/Ag salt/Al salt complex-es for olefin separation[J]. Polymers, 2020,12(3):667.

doi: 10.3390/polym12030667 |

| [24] | Xin Q, Zhang Y, Shi Y, et al. Tuning the performance of CO2 seps-ration membranes by incorporating multifunctional modified silica microspheres into polymer matrix[J]. Journal of Membrane Scien-ce, 2016,514:73-85. |

| [25] |

Robeson L M. The upper bound revisited[J]. Journal of Membrane Science, 2008,320(1/2):390-400.

doi: 10.1016/j.memsci.2008.04.030 |

| [26] |

Laghaei M, Sadeghi M, Ghalei B, et al. The role of compatibility be-tween polymeric matrix and silane coupling agents on the perfor-mance of mixed matrix membranes:Polyethersulfone/MCM-41[J]. Journal of Membrane Science, 2016,513:20-32.

doi: 10.1016/j.memsci.2016.04.039 |

| [27] |

Xin Q, Liu T, Li Z, et al. Mixed matrix membranes composed of sul-fonated poly(ether ether ketone) and a sulfonated metal-organic framework for gas separation[J]. Journal of Membrane Science, 2015,488:67-78.

doi: 10.1016/j.memsci.2015.03.060 |

| [28] | Michael Lartey. Fabrication of MMMs with improved gas separation properties using externally-functionalized MOF particles[J]. Jour-nal of Materials Chemistry A, 2015,3(9):5014-5022. |

| [29] |

Liu Y, Peng D, He G, et al. Enhanced CO2 permeability of membr-anes by incorporating polyzwitterion@CNT composite particles in-to polyimide matrix[J]. ACS Applied Materials & Interfaces, 2014,6(15):13051-13060.

doi: 10.1021/am502936x pmid: 25068977 |

| [30] |

Bastani D, Esmaeili N, Asadollahi M. Polymeric mixed matrix mem-branes containing zeolites as a filler for gas separation applicatio-ns:A review[J]. Journal of Industrial and Engineering Chemistry, 2013,19(2):375-393.

doi: 10.1016/j.jiec.2012.09.019 |

| [31] | Junaidi M U M, Leo C P, Ahmad A L, et al. Fluorocarbon function-alized SAPO-34 zeolite incorporated in asymmetric mixed matrix membranes for carbon dioxide separation in wet gases[J]. Micropo-rous & Mesoporous Materials, 2015,206:23-33. |

| [32] |

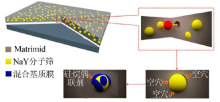

Amooghin A E, Omidkhah M, Kargari A. The effects of aminosilane grafting on NaY zeolite-Matrimid ® 5218 mixed matrix membranes for CO2/CH4 separation [J]. Journal of Membrane Science, 2015,490:364-379.

doi: 10.1016/j.memsci.2015.04.070 |

| [33] |

Su N C, Buss H G, Mccloskey B D, et al. Enhancing separation and mechanical performance of hybrid membranes through nanoparti-cle surface modification[J]. ACS Macro Letters, 2015,4(11):1239-1243.

doi: 10.1021/acsmacrolett.5b00681 |

| [34] |

Ma L, Svec F, Tan T, et al. Mixed matrix membrane based on cross-linked poly[(ethylene glycol) methacrylate] and metal-organic framework for efficient separation of carbon dioxide and metha-ne[J]. ACS Applied Nano Materials, 2018,1(6):2808-2818.

doi: 10.1021/acsanm.8b00459 |

| [35] | Zhang J, Xin Q, Li X, et al. Mixed matrix membranes comprising aminosilane-functionalized graphene oxide for enhanced CO2 separation[J]. Journal of Membrane Science, 2019,570:343-354. |

| [36] |

Li X, Ma L, Zhang H, et al. Synergistic effect of combining carbon nanotubes and graphene oxide in mixed matrix membranes for effi-cient CO2 separation[J]. Journal of Membrane Science, 2015,479:1-10.

doi: 10.1016/j.memsci.2015.01.014 |

| [37] |

Sarfraz M, Ba-Shammakh M. Pursuit of efficient CO2-capture mem-branes:graphene oxide-and MOF-integrated Ultrason® membran-es[J]. Polymer Bulletin, 2018,75(11):5039-5059.

doi: 10.1007/s00289-018-2301-6 |

| [38] | Feijani E A, Mahdavi H, Tavassoli A. Synjournal and gas permselec-tivity of CuBTC-GO-PVDF mixed matrix membranes[J]. New Jo-urnal of Chemistry, 2018,42(14):12013-12023. |

| [39] |

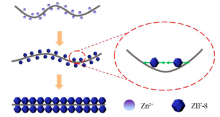

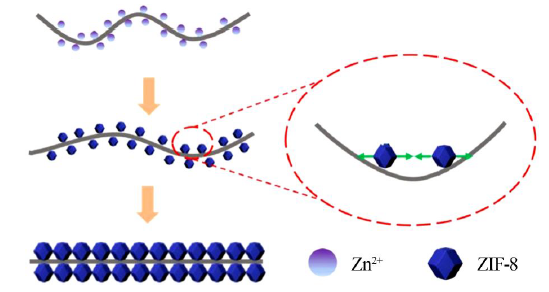

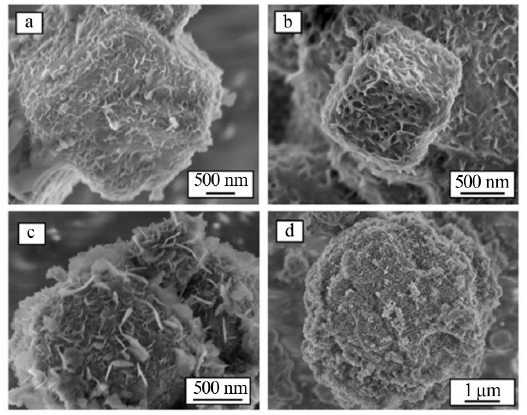

Yang K, Dai Y, Ruan X, et al. Stretched ZIF-8@GO flake-like fi-llers via pre-Zn(Ⅱ)-doping strategy to enhance CO2 permeation in mixed matrix membranes[J]. Journal of Membrane Science, 2020,601:117934.

doi: 10.1016/j.memsci.2020.117934 |

| [40] |

Lin R, Ge L, Liu S, et al. Mixed-matrix membranes with metal-orga-nic framework-decorated CNT fillers for efficient CO2 separation[J]. ACS Applied Materials & Interfaces, 2015,7(27):14750-14757.

doi: 10.1021/acsami.5b02680 pmid: 26090690 |

| [41] | Tanh Jeazet H B, Sorribas S, Román-Marín J M, et al. Increased se-lectivity in CO2/CH4 separation with mixed-matrix membranes of polysulfone and mixed-MOFs MIL-101(Cr) and ZIF-8[J]. Euro-pean Journal of Inorganic Chemistry, 2016,27:4363-4367. |

| [42] |

Castarlenas S, Téllez C, Coronas J. Gas separation with mixed ma-trix membranes obtained from MOF UiO-66-graphite oxide hybri-ds[J]. Journal of Membrane Science, 2017,526:205-211.

doi: 10.1016/j.memsci.2016.12.041 |

| [43] | Sarfraz M, Ba-Shammakh M. Synergistic effect of incorporating ZIF-302 and graphene oxide to polysulfone to develop highly se-lective mixed-matrix membranes for carbon dioxide separation from wet post combustion flue gases[J]. Journal of Industrial & Engin-eering Chemistry, 2016,36:154-162. |

| [44] |

Gong H, Lee S S, Bae T H, et al. Mixed-matrix membranes contain-ing inorganically surface-modified 5A zeolite for enhanced CO2/CH4 separation[J]. Microporous and Mesoporous Materials, 2017,237:82-89.

doi: 10.1016/j.micromeso.2016.09.017 |

| [45] |

Rodenas T, Luz I, Prieto G, et al. Metal-organic framework nano-sheets in polymer composite materials for gas separation[J]. Na-ture Materials, 2015,14(1):48-55.

doi: 10.1038/nmat4113 pmid: 25362353 |

| [46] | Sabetghadam A, Seoane B, Keskin D, et al. Metal organic frame-work crystals in mixed-matrix membranes:impact of the filler mo-rphology on the gas separation performance[J]. Advanced Functi-onal Materials, 2016,26(18):3154-3163. |

| [1] | Xing Shujian;Zang Jiazhong;Liu Wei;Liu Guanfeng;Sun Chunhui;Yu Haibin. Progress on industrial application of molecular sieve adsorbents [J]. INORGANICCHEMICALSINDUSTRY, 2009, 0(3): 0-0. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|