Inorganic Chemicals Industry ›› 2020, Vol. 52 ›› Issue (11): 79-85.doi: 10.11962/1006-4990.2019-0664

• Environment·Health·Safety • Previous Articles Next Articles

Effect of heat-treated desulfurized gypsum on properties of super sulfated cement

Zhou Jianwei( ),Cheng Baojun,Yu Baoying(

),Cheng Baojun,Yu Baoying( ),Ma Pengfei,He Pingxian

),Ma Pengfei,He Pingxian

- Building Materials Science Academy of China West Construction Group Co.,Ltd.,Chengdu 610094,China

-

Received:2020-05-20Online:2020-11-10Published:2020-12-01 -

Contact:Yu Baoying E-mail:jianzhucat@163.com;yby2872@163.com

CLC Number:

Cite this article

Zhou Jianwei,Cheng Baojun,Yu Baoying,Ma Pengfei,He Pingxian. Effect of heat-treated desulfurized gypsum on properties of super sulfated cement[J]. Inorganic Chemicals Industry, 2020, 52(11): 79-85.

share this article

"

| 原料 | w(CaO) | w(SiO2) | w(Al2O3) | w(MgO) | w(K2O) | w(SO3) | w(Na2O) |

|---|---|---|---|---|---|---|---|

| 熟料 | 69.19 | 25.12 | 2.11 | 1.26 | 0.667 | 0.596 | 0.367 |

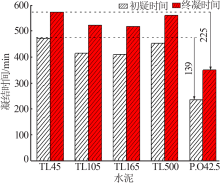

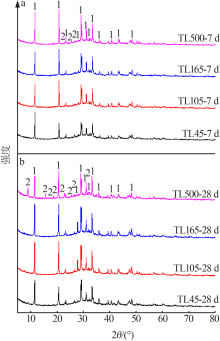

| 矿粉 | 40.39 | 35.56 | 11.55 | 7.16 | 0.517 | — | 1.04 |

| 石膏 | 48.75 | 4.66 | 1.27 | 0.876 | 0.173 | 40.2 | 0.375 |

| 原料 | w(Fe2O3) | w(P2O5) | w(TiO2) | w(ZnO) | w(MnO) | w(Cl) | w(其他) |

| 熟料 | 0.232 | 0.145 | 0.127 | 0.063 6 | 0.06 | 0.052 6 | 0.029 8 |

| 矿粉 | 0.398 | — | 1.59 | 0.06 | 0.13 | — | 1.605 |

| 石膏 | 0.527 | 0.456 | 0.056 6 | 0.033 | 0.011 7 | 1.27 | 1.341 7 |

| [1] | 卢兰萍, 李阳, 王稷良, 等. 脱硫石膏综合利用的现状与分析[J].粉煤灰综合利用, 2019(3):95-98. |

| [2] | 张凡凡, 陈超, 张西兴, 等. 不同来源石膏的性能特点与应用分析[J]. 无机盐工业, 2017,49(8):10-13. |

| [3] | 昌松. 火电厂湿法烟气脱硫脱硫石膏脱水问题分析及改进措施[J].科学技术创新, 2019(31):44-45. |

| [4] | 尤彩霞, 李军, 孙娜, 等. 电厂脱硫石膏制水泥缓凝剂二水石膏的研究[J]. 无机盐工业, 2019,51(12):71-74. |

| [5] | 苏清发, 周勇敏, 陈永瑞, 等. 脱硫灰/脱硫石膏作为水泥缓凝剂的水化行为[J]. 硅酸盐学报, 2016,44(5):663-667. |

| [6] | 莫奕新, 庞建勇, 黄金坤, 等. 粉煤灰-脱硫石膏复合水泥土渗透性试验研究[J].新型建筑材料, 2018(1):122-125. |

| [7] | 饶益杰, 汪丽娟, 尹祥国, 等. 脱硫石膏代替天然石膏生产加气混凝土砌块的可行性及工艺研究[J].新型建筑材料, 2019(7):75-78. |

| [8] | 李亮. 利用脱硫石膏制备发泡轻质材料的研究[J]. 无机盐工业, 2018,50(11):49-52. |

| [9] | 闫国斌, 许立顺, 赵建文. 利用脱硫灰烧结渣制备新型充填胶凝材料的试验[J]. 矿业研究与开发, 2015,35(12):22-27. |

| [10] | 魏微, 杨志强, 高谦. 全尾砂新型胶凝材料的胶结作用[J]. 建筑材料学报, 2013,16(5):881-887. |

| [11] | 胡军. 脱硫石膏在水泥稳定碎石基层中的工程应用研究[J].城市道桥与防洪, 2014(4):234-237. |

| [12] | 石婧, 黄超, 刘娟, 等. 脱硫石膏不同施用量对新疆盐碱土壤改良效果及作物产量的影响[J]. 环境工程学报, 2018,12(6):1800-1807. |

| [13] | 阿斯古丽·阿吾提, 祁通, 刘国宏, 等.脱硫石膏改良碱化土壤施用技术规程[J].农业科技通讯, 2019(10):204-205. |

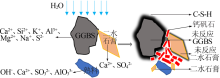

| [14] | 刘数华, 王露, 余保英. 超硫酸盐水泥的水化机理及工程应用综述[J].混凝土世界, 2018(10):46-51. |

| [15] |

Collier N C, Milestone N B, Gordon L E, et al. The suitability of a supersulfated cement for nuclear waste immobilisation[J]. Journal of Nuclear Materials, 2014,452(1/2/3):457-464.

doi: 10.1016/j.jnucmat.2014.05.078 |

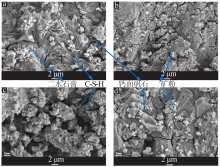

| [16] | 陆建鑫, 水中和, 田素芳, 等. 超硫酸盐水泥与波特兰水泥混凝土显微结构与性能的比较研究[J].武汉理工大学学报, 2013(5):1-7. |

| [17] | Juenger M C G, Winnefeld F, Provis J L, et al. Advances in alterna-tive cementitious binders[J]. Cement & Concrete Research, 2011,41(12):1232-1243. |

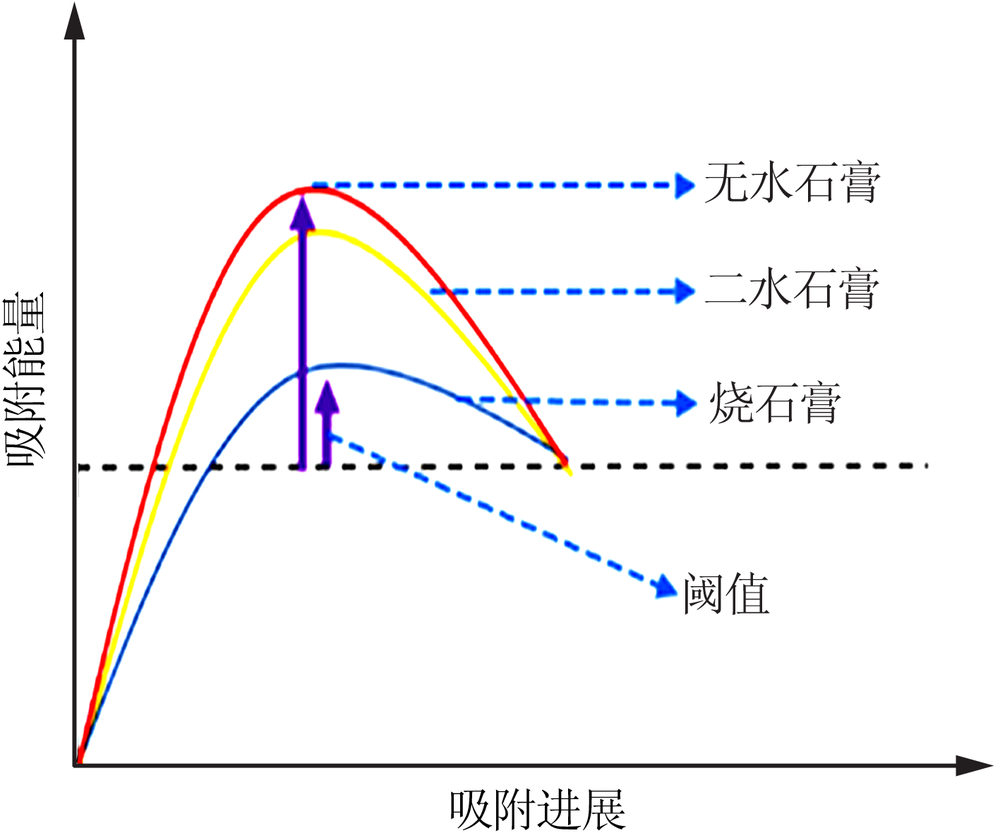

| [18] | 余保英, 高育欣, 王军. 含不同石膏种类的超硫酸盐水泥的水化行为[J]. 建筑材料学报, 2014,17(6):965-971. |

| [19] | 孙正宁, 周健, 慕儒, 等. 新型超硫酸盐水泥水化硬化机理[J]. 硅酸盐通报, 2019,38(8):2362-2368. |

| [20] | 许长红, 王露, 刘数华. 一种超低水化热水泥——超硫酸盐水泥[J].混凝土世界, 2017(10):38-42. |

| [21] | 方佩佩, 刘数华. 改性磷石膏基超硫酸盐水泥研究进展[J]. 硅酸盐通报, 2019,38(8):2430-2434. |

| [22] | 欧阳嘉艺, 刘数华. 磷石膏改性机制及其在超硫酸盐水泥中的应用进展[J].混凝土世界, 2019(9):60-66. |

| [23] | 郭玉萍, 王海波, 牛全林. 超硫酸盐水泥的组成、制备及性能[J]. 工程质量, 2016,34(11):66-68. |

| [24] |

Collier N, Li X, Bai Y, et al. The effect of sulfate activation on the early age hydration of BFS:PC composite cement[J]. Journal of Nuclear Materials, 2015,464:128-134.

doi: 10.1016/j.jnucmat.2015.04.044 |

| [25] | Cabrera-luna K, Maldonado-bandala E, Nieves-mendoza D, et al. Supersulfated binders based on volcanic raw material:optimiza-tion,microstructure and reaction products[J]. Construction & Bu-ilding Materials, 2018,176:145-155. |

| [26] | Abouhussien A A, Hassan A A A.Monitoring early agestrength-gain of SCC with different supplementary cementitious materials using acoustic emission sensors[J]. Construction and Bulding Ma-terials, 2019,229:116858. |

| [27] |

Liu Shuhua, Wang Lu, Gao Yuxin, et al. Influence of fineness on hydration kinetics of supersulfated cement[J]. Thermochimica Acta, 2015,605:37-42.

doi: 10.1016/j.tca.2015.02.013 |

| [1] | Fan Qingke,Meng Qinghua,Luo Fengyu. Study on preparation and properties of cathode materials for vehicle lithium battery [J]. Inorganic Chemicals Industry, 2021, 53(1): 44-49. |

| [2] | Zhao Shihao,Lin Xihua,Ma Pengfei,Yuan Yijin,Gao Yuxin,Zhang Ping,Zhou Dali. Study on formulation calculation of phosphogypsum-based composite cementitious materials based on expansion and failure of critical AFt [J]. Inorganic Chemicals Industry, 2020, 52(9): 91-95. |

| [3] | Zheng Shaocong,Wang Fan,Zhu Liping,Xu Chengkun. Experimental study on influence of phosphogypsum with modified phosphorus slag powder [J]. Inorganic Chemicals Industry, 2020, 52(1): 73-75. |

| [4] | LI San-Xi, SONG De-Zhi, ZHANG Wen-Zheng, WANG Zan, LI Tian-Sheng. Effect of preparation process on the preparation of BiFeO3 film by sol-gel process [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(8): 43-. |

| [5] | CHENG Yun, LIN Mei-Qing, ZHAO Min. Research on preparation of hemihydrate gypsum whiskers from desulfurized gypsum [J]. INORGANICCHEMICALSINDUSTRY, 2016, 48(2): 63-. |

| [6] | Liu Jinping;Zhao Hong;Song Xiaoli;Li Xiaolei. Effects of calcination temperature on structure of titanium oxide photocatalyst [J]. INORGANICCHEMICALSINDUSTRY, 2009, 0(9): 0-0. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|