Inorganic Chemicals Industry ›› 2020, Vol. 52 ›› Issue (2): 23-29.doi: 10.11962/1006-4990.2019-0153

• Research & Development • Previous Articles Next Articles

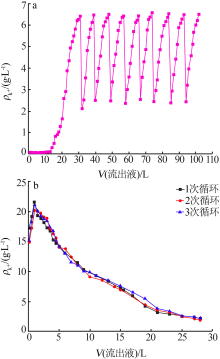

Process of potassium extraction from bittern with modified clinoptilolite

Wang Mucun1,Guo Xiaofu1,2,Zhao Yingying1,2,Yuan Junsheng1,2( )

)

- 1. School of Chemical Engineering and Technology,Hebei University of Technology,Tianjin 300130,China

2. Engineering Research Center of Seawater Utilization Technology,Ministry of Education

-

Received:2019-08-25Online:2020-02-10Published:2020-02-26 -

Contact:Yuan Junsheng E-mail:jsyuan2012@126.com

CLC Number:

Cite this article

Wang Mucun,Guo Xiaofu,Zhao Yingying,Yuan Junsheng. Process of potassium extraction from bittern with modified clinoptilolite[J]. Inorganic Chemicals Industry, 2020, 52(2): 23-29.

share this article

| [1] | 沈镭, 武娜, 钟帅 , 等. 经济新常态下中国矿业供给侧改革发展战略研究[J]. 中国人口、资源与环境, 2017,27(7):8-17. |

| [2] | 陈峥, 刘素芹, 张金娜 . 高纯氧化镁的研究与开发[J]. 盐科学与化工, 2017,46(4):32-35. |

| [3] | 袁俊生, 吴举, 邓会宁 , 等. 中国海盐苦卤综合利用技术的开发进展[J]. 盐业与化工, 2006,35(4):33-37. |

| [4] | 李东洋, 李先国, 冯丽娟 , 等. 卤水中钾和镁的利用[J]. 无机盐工业, 2011,43(11):12-14. |

| [5] | 王世忠 . 以苦卤为原料制取氯化钾的兑卤新工艺[J]. 盐业与化工, 2014,43(5):1-3. |

| [6] | 张浩, 祝桂林, 李明达 . 食用氯化钾生产工艺节能改造[J]. 无机盐工业, 2014,46(2):51-53. |

| [7] | 田凤超, 王惠霞 . 苦卤脱硫改善氯化钾生产工艺的实验研究[J]. 盐业与化工, 2015,44(11):40-42. |

| [8] | 詹光, 郭占成 . 从KCl-NaCl浸出液中分离提纯氯化钾的多效蒸发结晶能耗分析研究[J]. 计算机与应用化学, 2014,31(5):555-561. |

| [9] | 袁俊生, 纪志永, 陈建新 . 海水化学资源利用技术的进展[J]. 化学工业与工程, 2010: 27, 110-116. |

| [10] | 袁俊生, 郭小甫, 王士钊 , 等. 一种基于耦合技术的大型富钾的方法及其装置:中国,107673372A[P]. 2018 -02-09. |

| [11] | 袁俊生, 吕铮 . 一种沸石法从海水提取硫酸钾的方法:中国,1386704A[P]. 2002 -12-25. |

| [12] | 谢英惠, 王维佳, 袁俊生 , 等. 模拟移动床连续处理含钙废水[J]. 非金属矿, 2017(1):89-92. |

| [13] | 王士钊 . 斜发沸石对钾离子交换特性的研究[D]. 天津:河北工业大学, 2002. |

| [14] | 袁俊生 . 离子交换法海水提钾技术的应用基础研究[D]. 天津:天津大学, 2005. |

| [15] | 袁俊生, 王静康 . 型斜发沸石Na+-K+离子交换特性研究(Ⅰ)——离子交换过程热力学特性[J]. 离子交换与吸附, 2004,20(6):541-547. |

| [16] | Yuan J S, Zhao Y Y, Li Q H , et al. Preparation of potassium ionic sieve membrane and its application on extracting potash from sea-water[J]. Separation and Purification Technology, 2012,99:55-60. |

| [17] | 袁俊生, 王静康 . 钠型斜发沸石Na+-K+离子交换特性研究(Ⅱ)——过程传质模型及动力学特性研究[J]. 离子交换与吸附, 2005,21(2):127-136. |

| [18] | Guo X F, Ji Z Y, Yuan J S , et al. Recovery of K+ rom concentrates from brackish and seawater desalination with modified clinoptilo-lite[J]. Desalination and Water Treatment, 2016,57(15):6829-6837. |

| [1] | Zhao Chuang,Fan Jingxin,Guo Chunlei,Li Ben,Li Bin,Zang Jiazhong,Wang Yang,Hou Liwei,Sun Zhenhai. Study on deactivation of diesel aromatic adsorbent [J]. Inorganic Chemicals Industry, 2020, 52(8): 98-102. |

| [2] | Li Yuanchao,Li Qiuxia,Yang Ruiguang,Xu Wenhui. Determination of sulfate ion content in high concentration bittern by ion chromatography [J]. Inorganic Chemicals Industry, 2019, 51(6): 69-71. |

| [3] | YANG Zhao-Juan, CUI Zhen-Hua, CUI Xiang-Mei, LI Xiao-Kun. Study on evaporation process of salt lake brine raw material of magnesium products [J]. INORGANICCHEMICALSINDUSTRY, 2012, 44(3): 25-. |

| [4] | ZHANG Yi-Yong, SHI Min, YU Xue-Feng, HU Cheng-Yin. Comparison of preparation technologies of high purity magnesia by limestone-bittern method and ammonia method [J]. INORGANICCHEMICALSINDUSTRY, 2011, 43(1): 45-47. |

| [5] | Zhang Mei;Yang Haining;Zhang Xiaoxia;Wang Chuanying. Preparation of polyaluminium ferrous chloride by using cryolite mother liquor [J]. INORGANICCHEMICALSINDUSTRY, 2010, 0(3): 0-0. |

| [6] | Cao Guojin;Wu Zhiming;Pang Yuna;Zhou Yuan. Effects of borate on determination of sulfate radical by barium sulfate gravimetric method in high boron bittern system [J]. INORGANICCHEMICALSINDUSTRY, 2009, 0(2): 0-0. |

| [7] | Zhang Zixing;Liu Hailong;Yang Fengling;Cheng Fangqin. Study on decoloration of bittern by hydrogen peroxide oxidative [J]. INORGANICCHEMICALSINDUSTRY, 2008, 0(3): 0-0. |

| [8] | Zhao Xiuping. Impact of organics in bittern on the quality of BaSO4 products [J]. INORGANICCHEMICALSINDUSTRY, 2008, 0(11): 0-0. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||

|