Inorganic Chemicals Industry ›› 2021, Vol. 53 ›› Issue (4): 73-75.doi: 10.11962/1006-4990.2020-0304

• Industrial Techniques • Previous Articles Next Articles

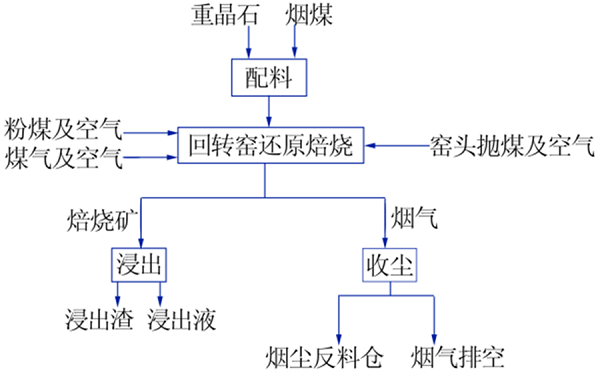

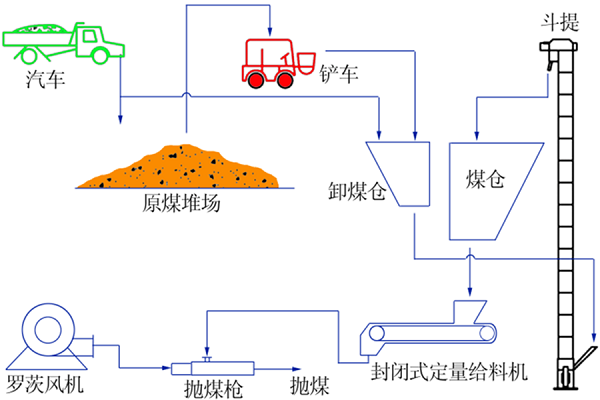

Study on rotary kiln reduction roasting production process of barite in Tianzhu of Guizhou

Yan Zhenzong1,Wang Dong2

- 1. Hebei Xinji Chemical Group,Shi Jiazhuang 052360,China

2. Changsha Research Institute of Mining and Metallurgy Co.,Ltd.